A variable compression ratio piston and a variable compression ratio engine

A technology with variable compression ratio, applied in the direction of engine control, engine components, machine/engine, etc., can solve the problems of increasing engine volume, high manufacturing cost, difficult mass production, etc., to avoid knocking, compact structure, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

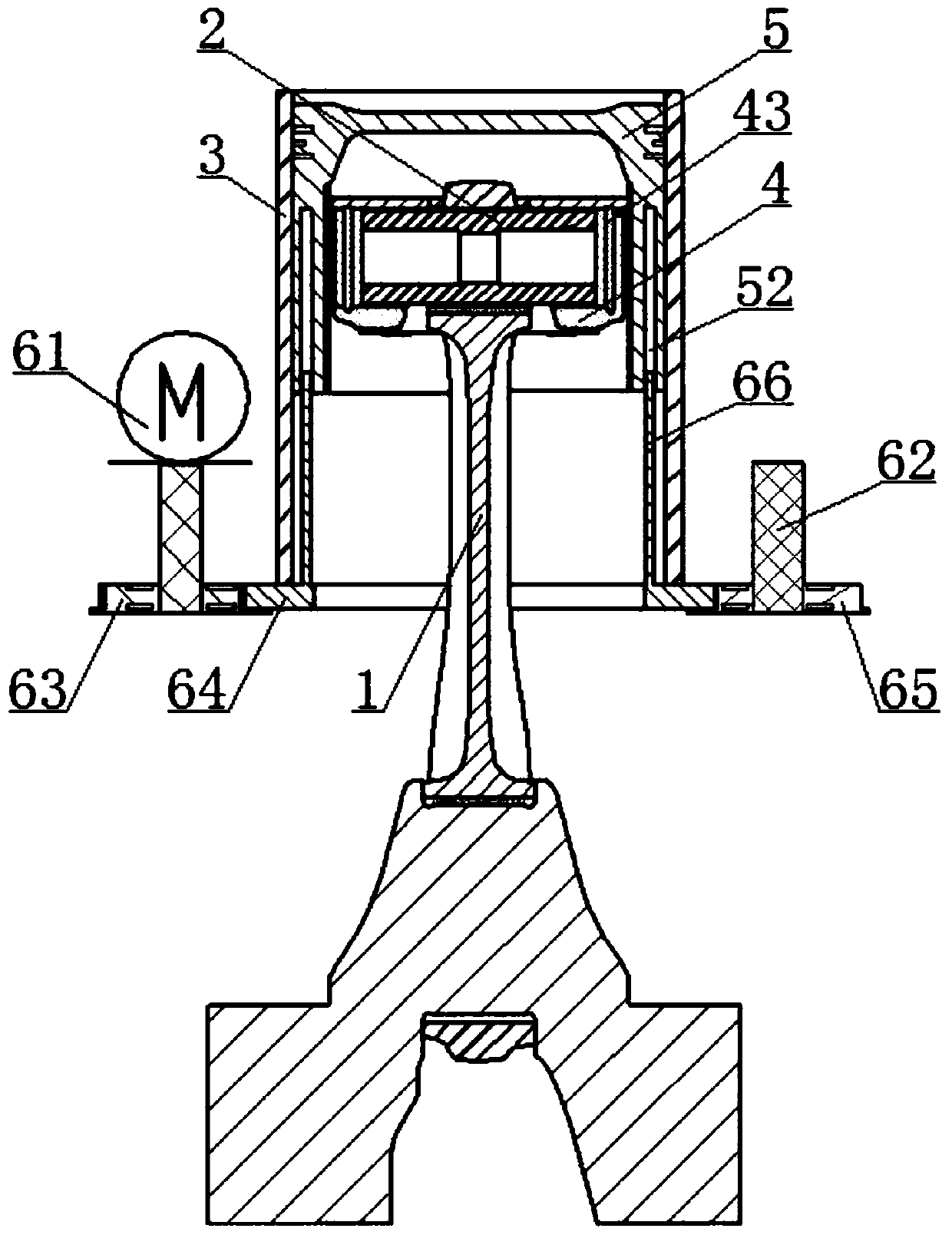

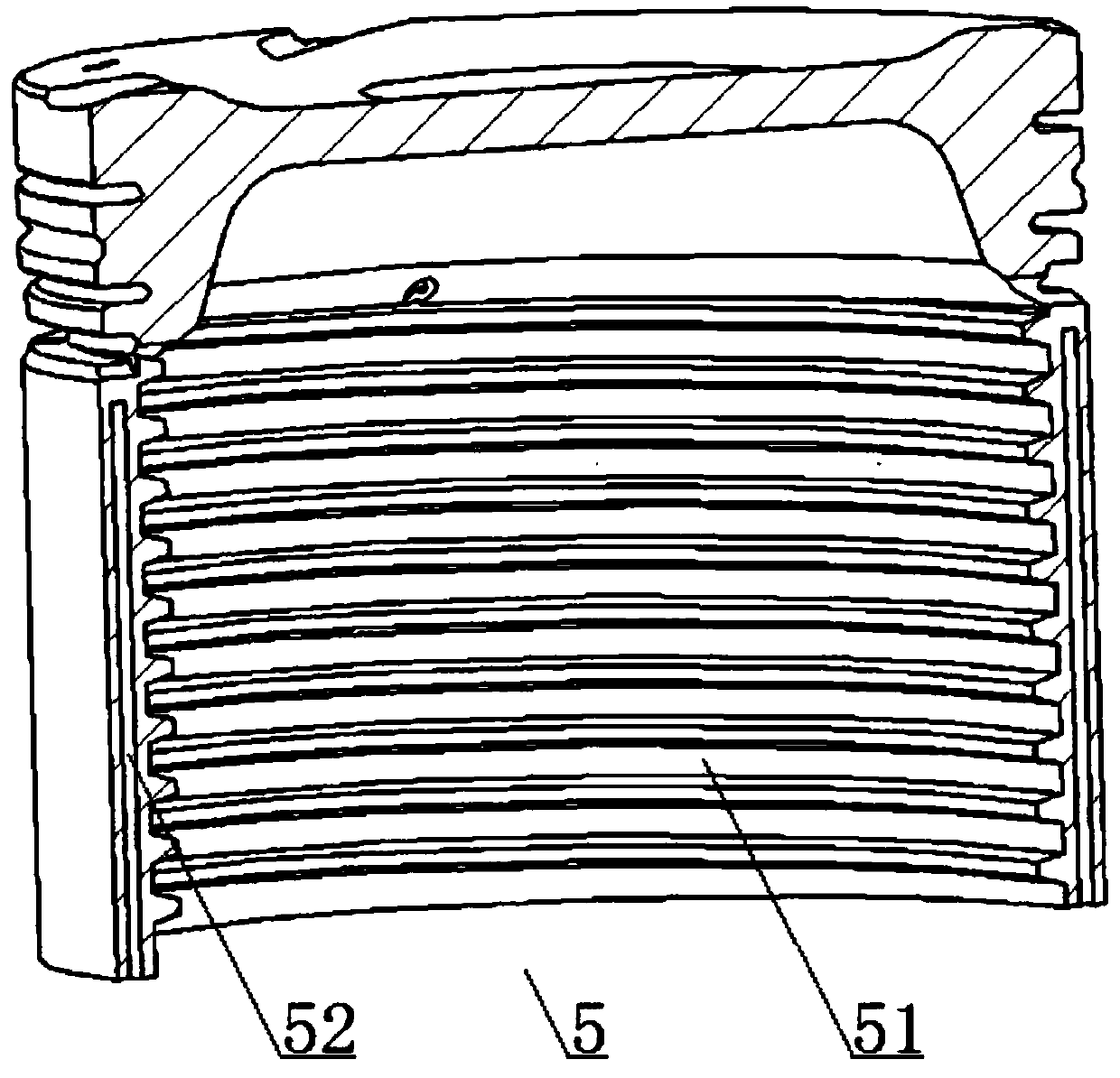

[0025] see Figure 1 to Figure 4 The described variable compression ratio piston is characterized in that it includes an inner piston 4 connected to the small end of the connecting rod 1 through a piston pin 2, an outer piston 5 threadedly engaged with the inner piston 4, and used for driving The drive mechanism 6 for moving the outer piston 5 up and down relative to the inner piston 4 . Through the driving mechanism 6, the outer piston 5 can move up and down relative to the inner piston 4, thereby changing the volume of the combustion chamber, realizing the change of the compression ratio, enabling the fuel to be fully burned, avoiding knocking, improving the thermal efficiency of the engine, and reducing fuel consumption and emissions.

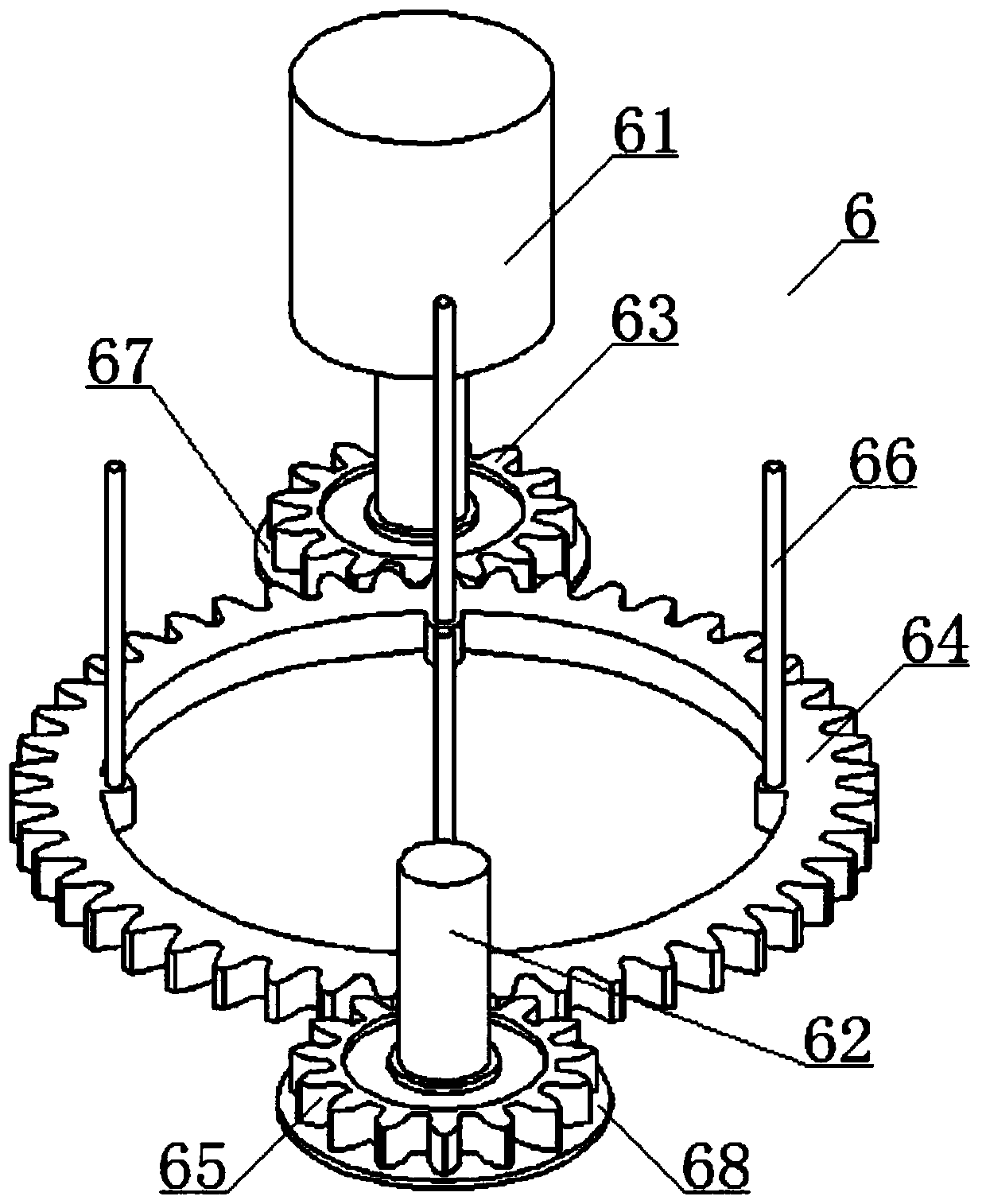

[0026] The drive mechanism 6 includes a drive motor 61 fixed at the end of the cylinder block 3, a drive gear 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com