Vehicle vibration energy recovery type shock absorber

A vibration energy recovery and shock absorber technology, applied in the direction of shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of limited frame space, high cost, low power generation efficiency, etc., and achieve high energy utilization , The effect of small energy loss and extreme energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

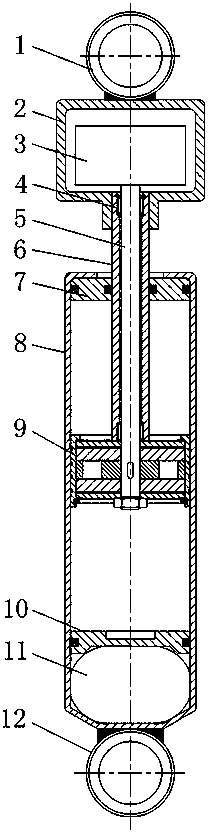

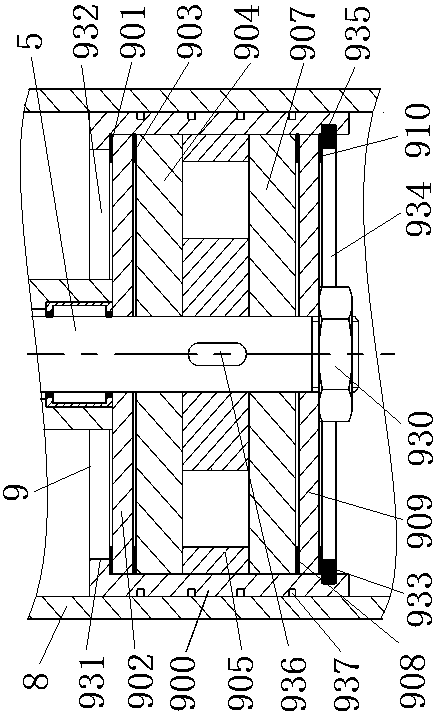

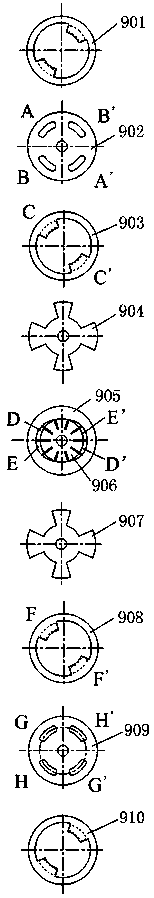

[0040] combine Figure 1~Figure 12 It can be seen that the vehicle vibration energy recovery type shock absorber of the present invention includes a cylinder 8 and a piston 9 matched with the cylinder 8, the end of the piston rod 6 of the piston 9 protrudes from the cylinder 8 and is fixed with the generator 3 , the piston rod 6 is a hollow tube, and the coaxial rotation of the piston rod 6 is connected with an output shaft 5. One end of the output shaft 5 is connected to the main shaft of the generator 3, and the other end is connected to the piston 9. The piston 9 includes a tubular casing 900, which is provided with an annular diaphragm spring A901, an upper valve seat 902, an annular diaphragm spring B903, an upper side plate 904, a vane motor, and a lower side in sequence from top to bottom. Plate 907, annular diaphragm spring C908, lower valve seat 909 and annular diaphragm spring D910, the rotor 906 of the vane motor is fixed to the output shaft 5, and the end of the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com