Assembling equipment and assembling method of LED strip lamp lens

An assembly equipment and lens technology, which is applied in the assembly equipment and field of LED strip lighting lenses, can solve the problems of low lens production efficiency, unstable product qualification rate, and uncoordinated cooperation, so as to avoid excessive dependence and realize automation And intelligence, improve the effect of quality and qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

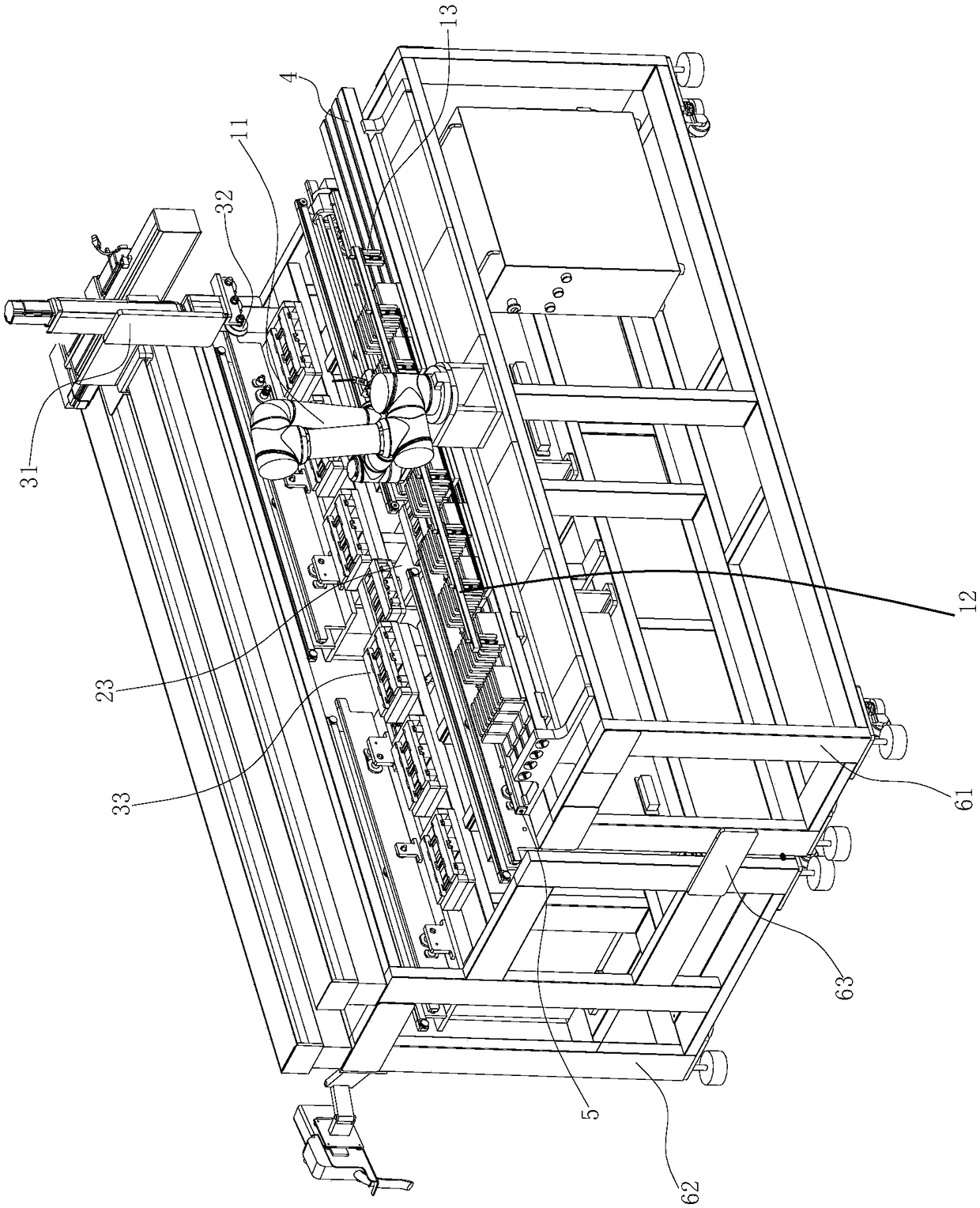

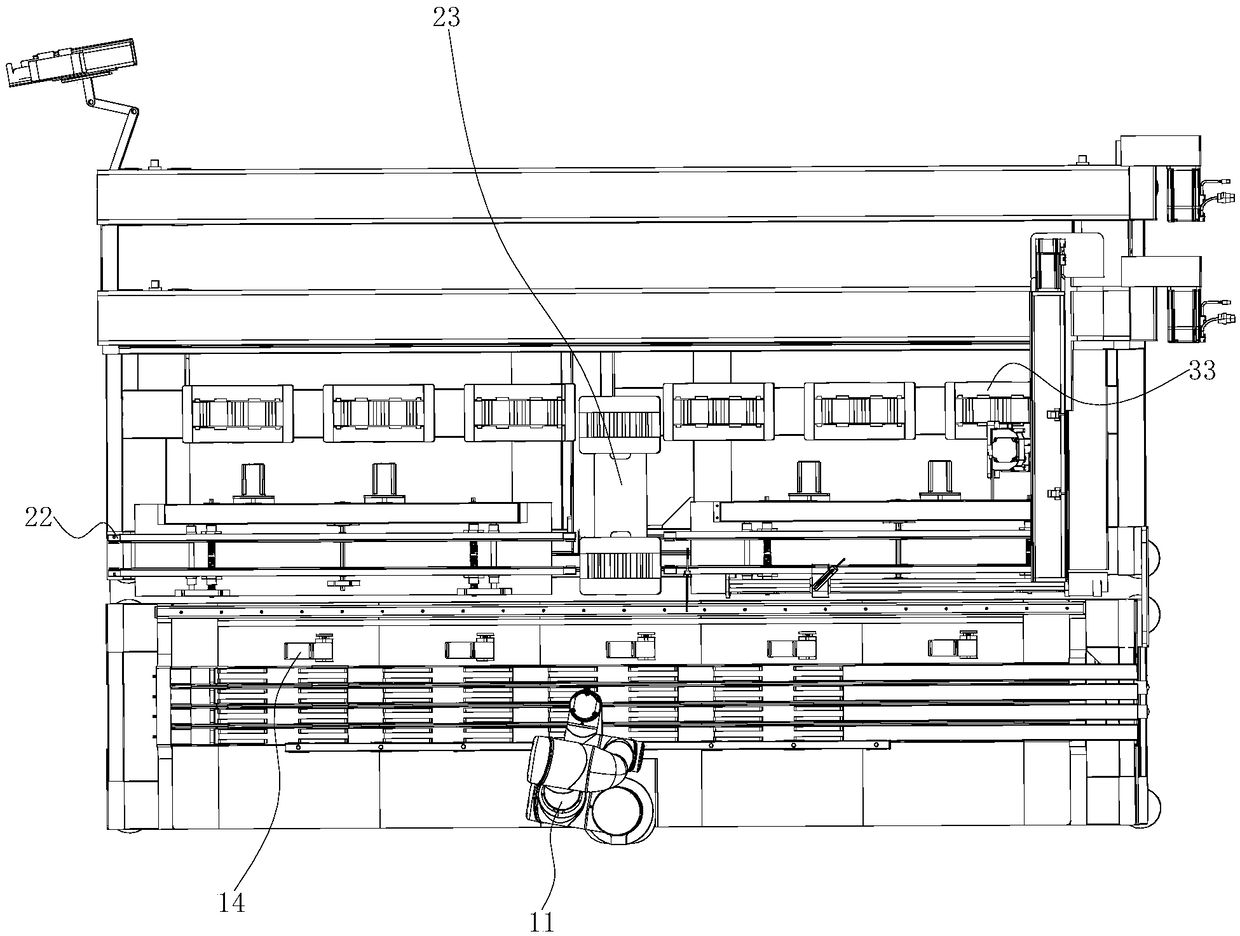

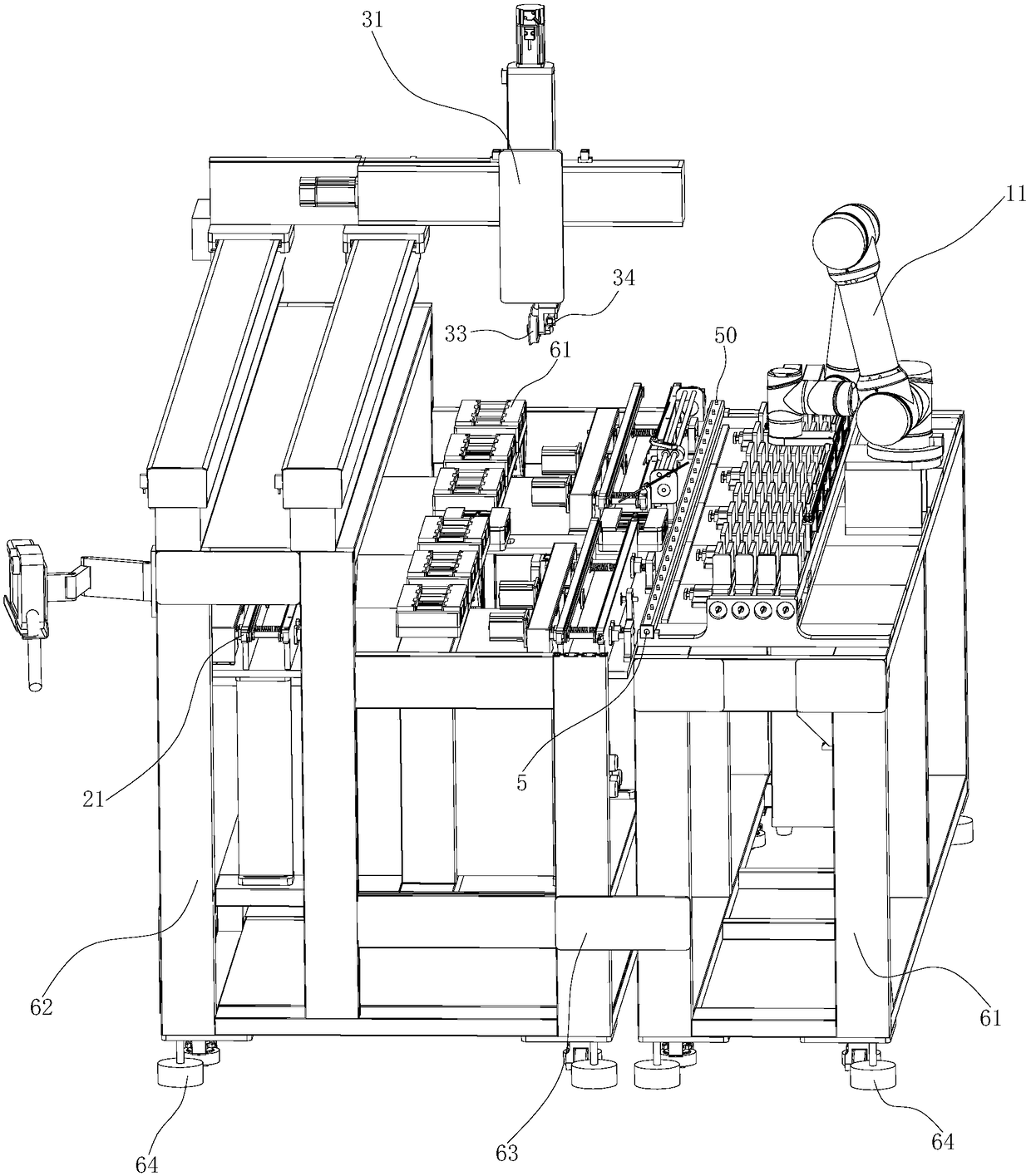

[0051] Such as Figure 1 ~ Figure 3 As shown, the assembly equipment for the LED strip lamp lens in this embodiment includes an equipment bracket, a lens transfer mechanism, a strip lamp aluminum bottom transfer mechanism, a lens assembly mechanism and a controller; the controller can use PLC as required, The controller can also be set at the appropriate position of the assembly equipment according to the needs; the lens transfer mechanism, the aluminum bottom transfer mechanism of the strip lamp and the lens assembly mechanism are installed on the equipment bracket; the equipment bracket can be in the form of double brackets, that is, the equipment Including the first bracket 61 and the second bracket 62, the first bracket 61 and the second bracket 62 are fastened together through the connecting plate 63; a supporting foot cup 64 can also be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com