Semiconductor refrigeration dehumidifier and dehumidification method thereof

A semiconductor and dehumidifier technology, applied in refrigerators, refrigeration and liquefaction, machine operation and other directions, can solve problems such as low energy efficiency, low failure rate and low service life, improve heat exchange efficiency, reduce flow pressure loss, simplify The effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

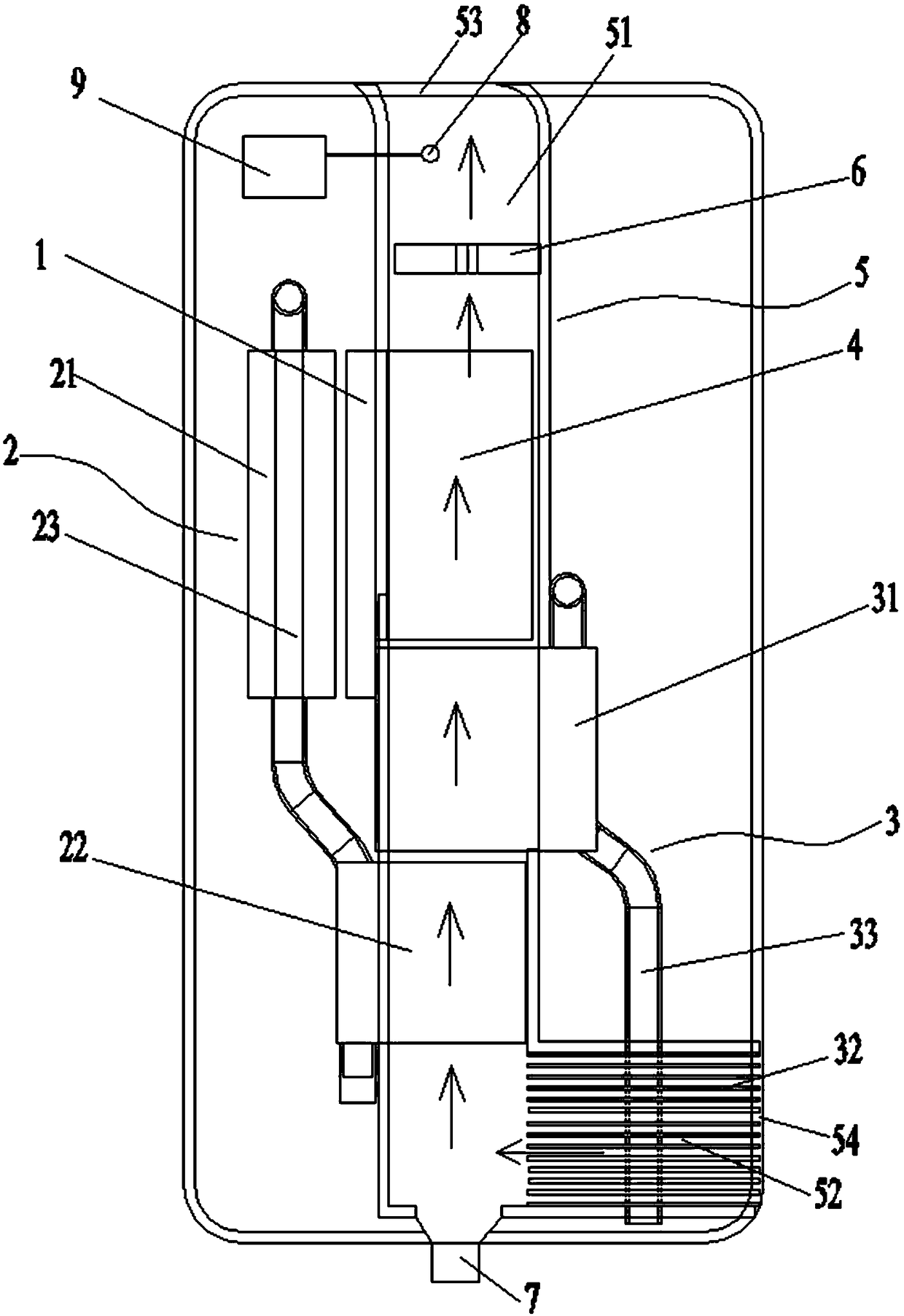

[0042] Such as figure 1 As shown, it is a schematic structural diagram of a semiconductor refrigeration dehumidifier provided in this embodiment, and the dehumidifier includes:

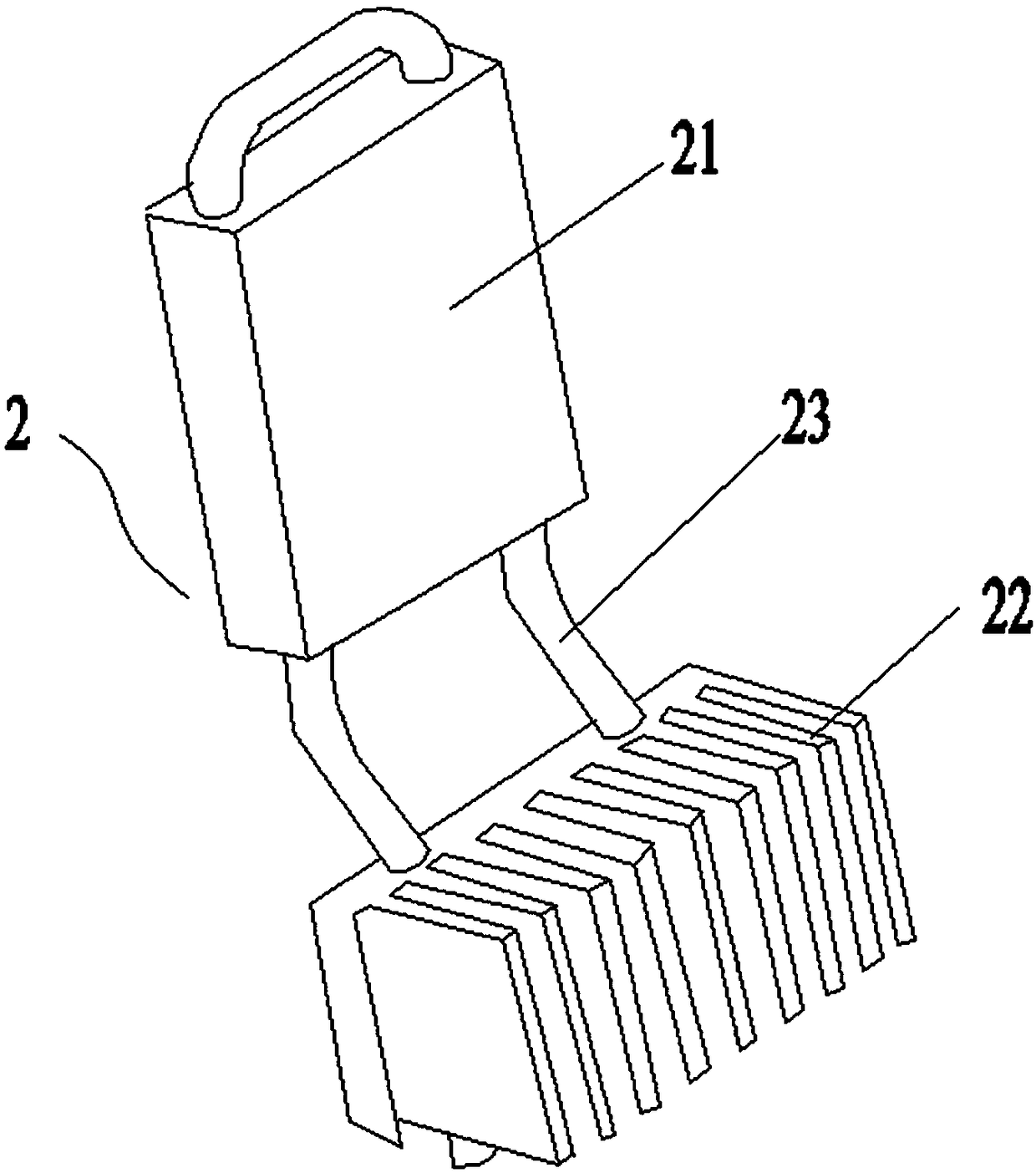

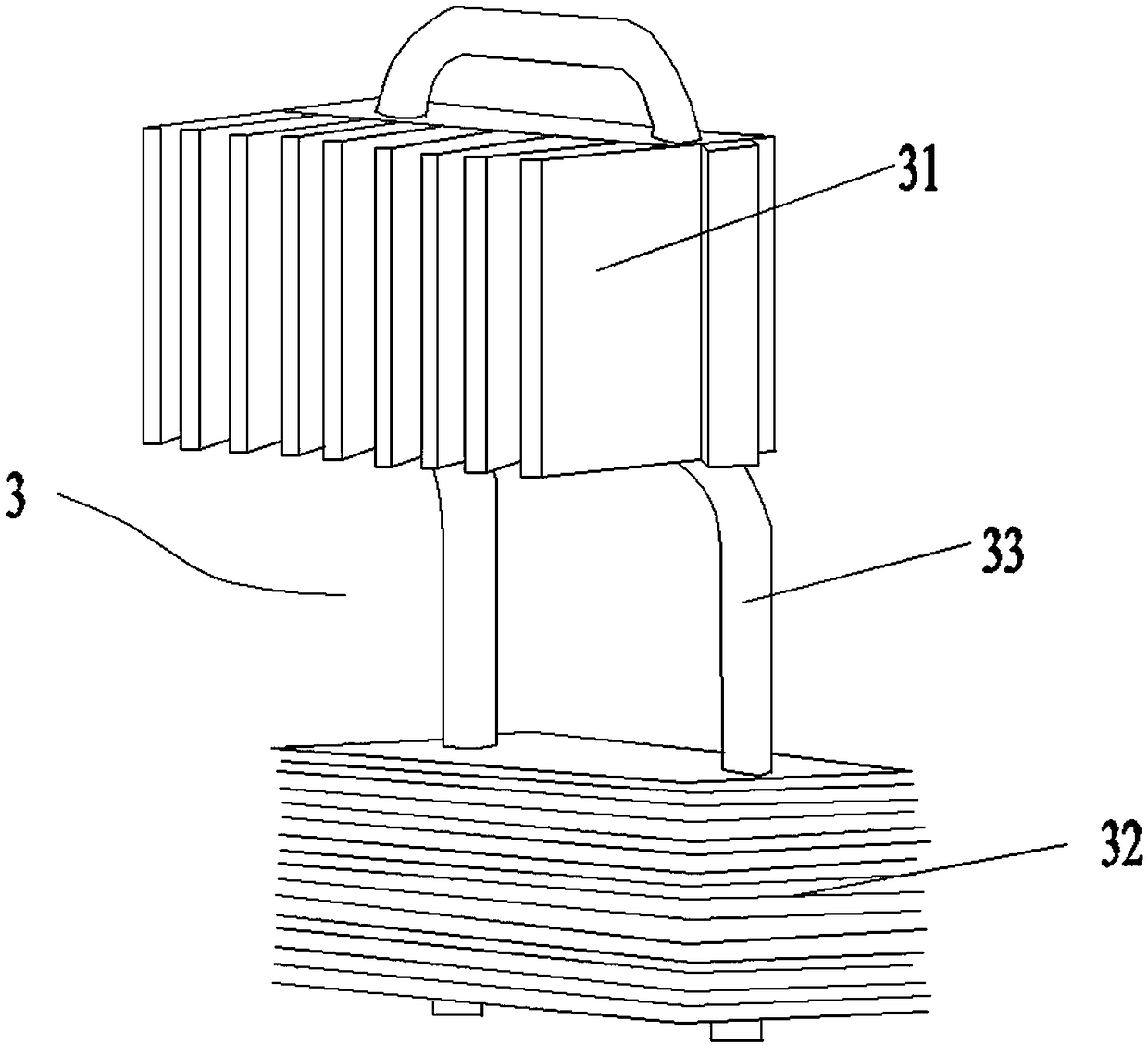

[0043] Semiconductor cooling chip 1, first heat transfer device 2, second heat transfer device 3, third heat transfer device 4, air duct 5, exhaust fan 6, water outlet 7;

[0044] The air passage 5 includes an air outlet 51 and an air inlet 52; the outlet of the air outlet 51 is provided with an air outlet 53, and the exhaust fan 6 is located at the air outlet 53; the air inlet The entrance of 52 is provided with an air inlet 54;

[0045] One end of the second heat transfer device 3 is located in the air inlet channel 52, pre-cools the air entering from the air inlet 54, and transfers the absorbed air heat to the other part of the second heat transfer device 3. one end;

[0046] One end of the first heat transfer device 2 is located in the air outlet channel 51 to secondary cool the pre-cooled air;...

Embodiment 2

[0059] Such as figure 1 As shown, it is a schematic structural diagram of a semiconductor refrigeration dehumidifier provided in this embodiment. The difference between this embodiment and the above embodiment is that a humidity sensor 8 is also provided at the air outlet 53 of the air outlet duct 51; A controller 9 is also arranged outside the air outlet 51; the controller 9 is electrically connected with the humidity sensor 8, the semiconductor refrigeration sheet 1 and the exhaust fan 6, receives the humidity data detected by the humidity sensor 8, and passes the humidity data at the air outlet 53 Analyze and control the operation of semiconductor refrigeration sheet 1 and exhaust fan 6.

[0060] The setting of the humidity sensor 3 and the controller facilitates real-time monitoring of the dehumidification effect of the dehumidifier.

[0061] The dehumidification method of the above-mentioned semiconductor refrigeration dehumidifier comprises the following steps:

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com