A camshaft end face detection device and method

A detection device and detection method technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems that the production quality cannot be effectively controlled in real time, cannot meet the requirements of production and delivery, and the production efficiency is not high. Convenient measurement, elimination of axial movement, accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

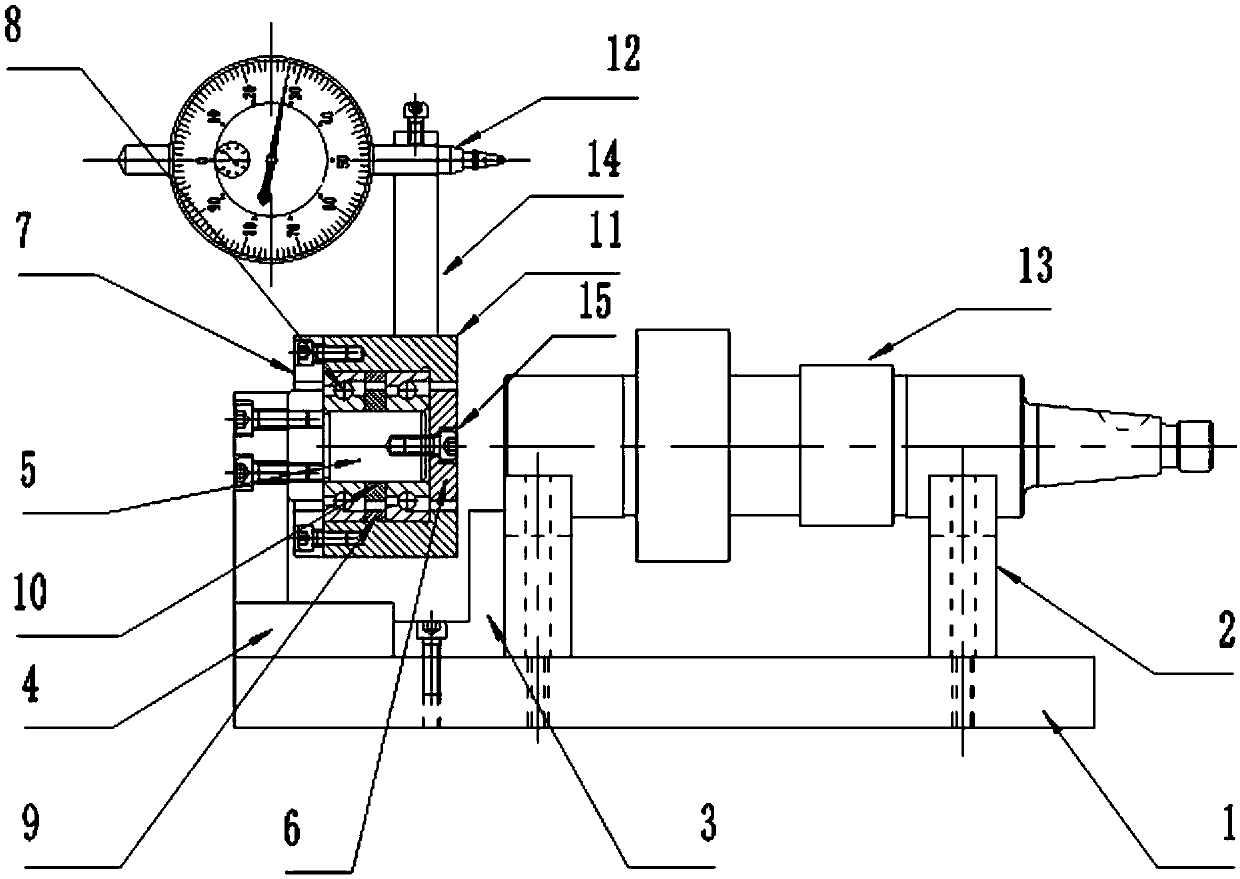

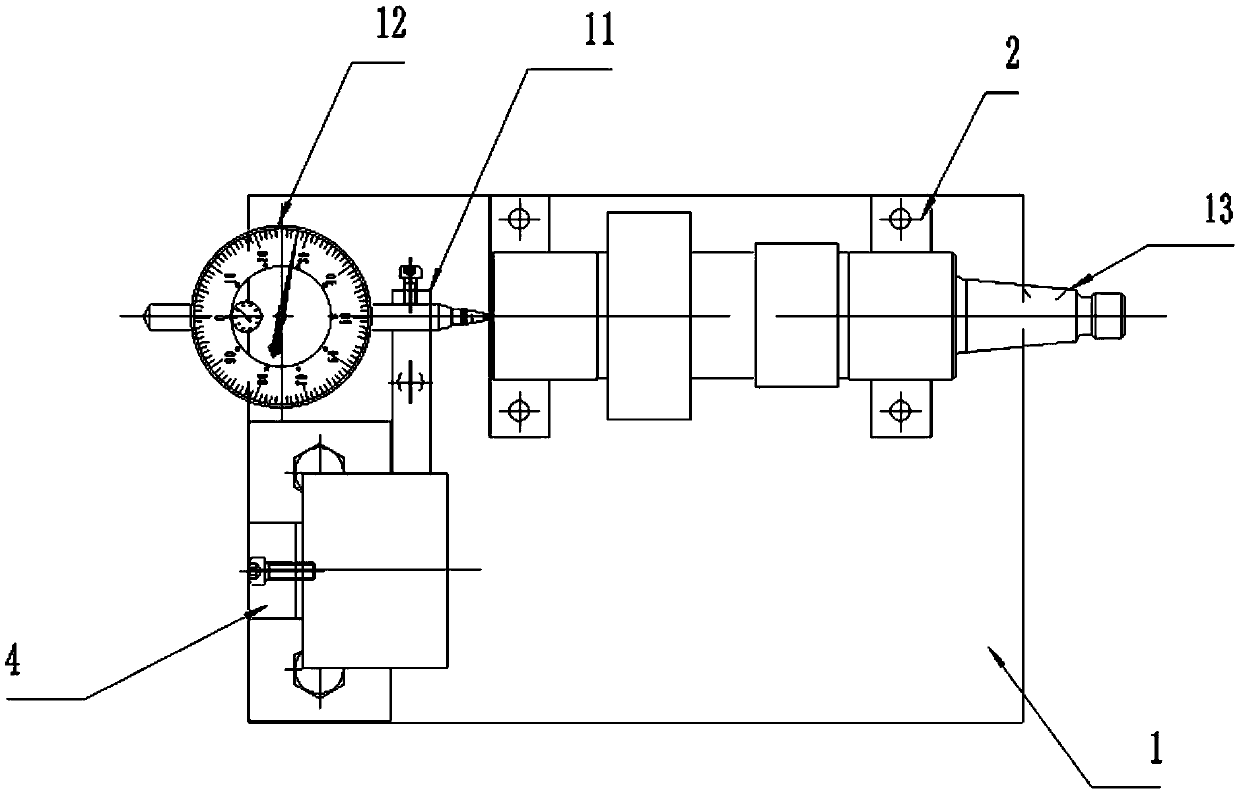

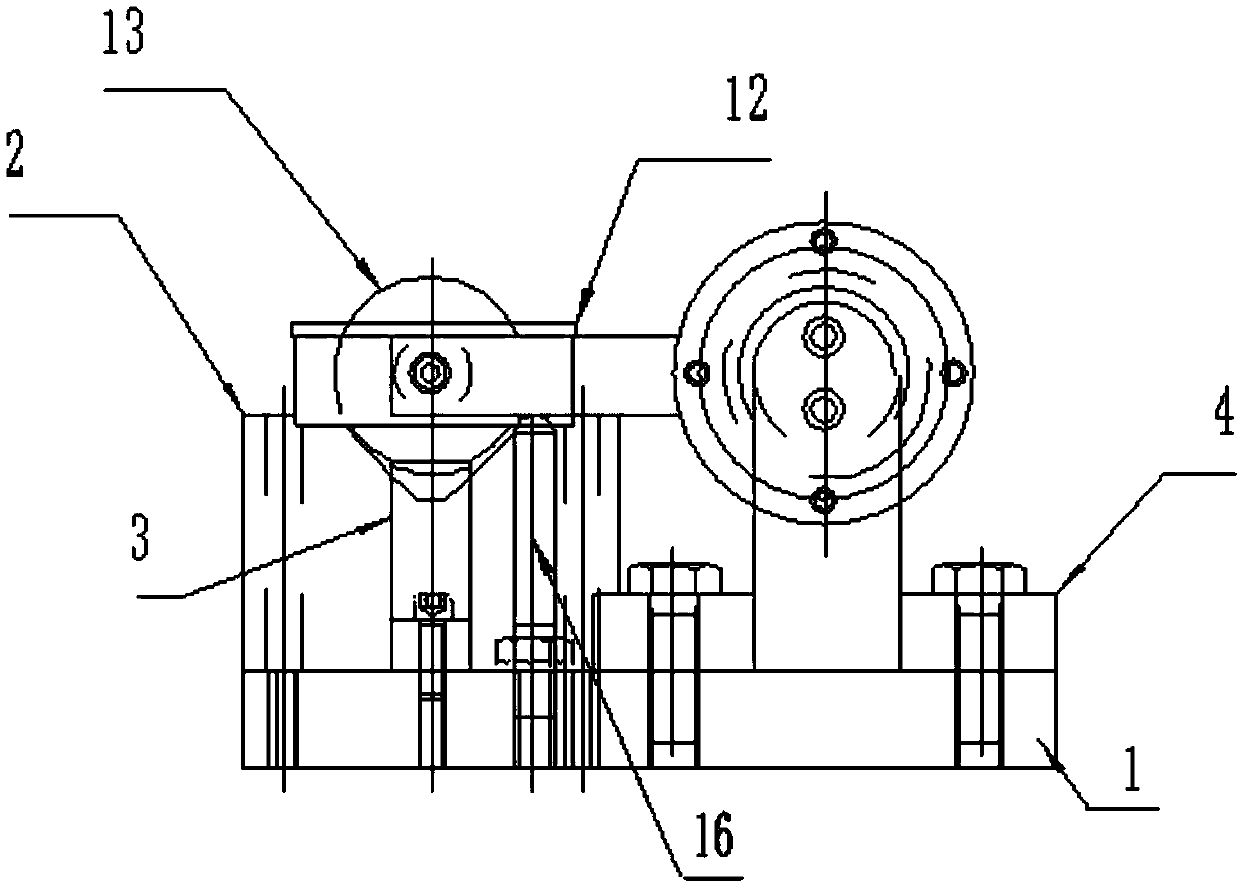

[0026] The invention provides a camshaft end face detection device, referring to Figure 1 to Figure 3 , including a bottom plate 1, on which a bearing seat 4, a positioning block 3 and a group of V-shaped blocks 2 for resting the camshaft 13 are fixed, the bearing seat 4 is located on the rear side of a group of V-shaped blocks 2, and the positioning The block 3 is located behind a group of V-shaped blocks 2, the bearing housing 4 is installed with an angular contact ball bearing 8, and the inner hole of the angular contact ball bearing 8 is installed with a mandrel 5, and the axis direction of the mandrel 5 is in line with a group of V-shaped blocks. The arrangement direction of the block 2 is parallel, the angular contact ball bearing 8 is covered with a bearing sleeve 11, the end cover 7 is fixed on the bearing seat 4, the mandrel 5 rotates in the space closed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com