Transmission case end face large-size form and location tolerance detection device and method based on checkerboard

A form and position tolerance and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of real-time online detection, slow detection speed, low efficiency, etc., to improve detection efficiency and transmission box quality, realize The effect of real-time online detection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is a detailed description of the detection device for the large-size shape and position tolerance of the end face of the transmission box based on the checkerboard standard plate in conjunction with the accompanying drawings.

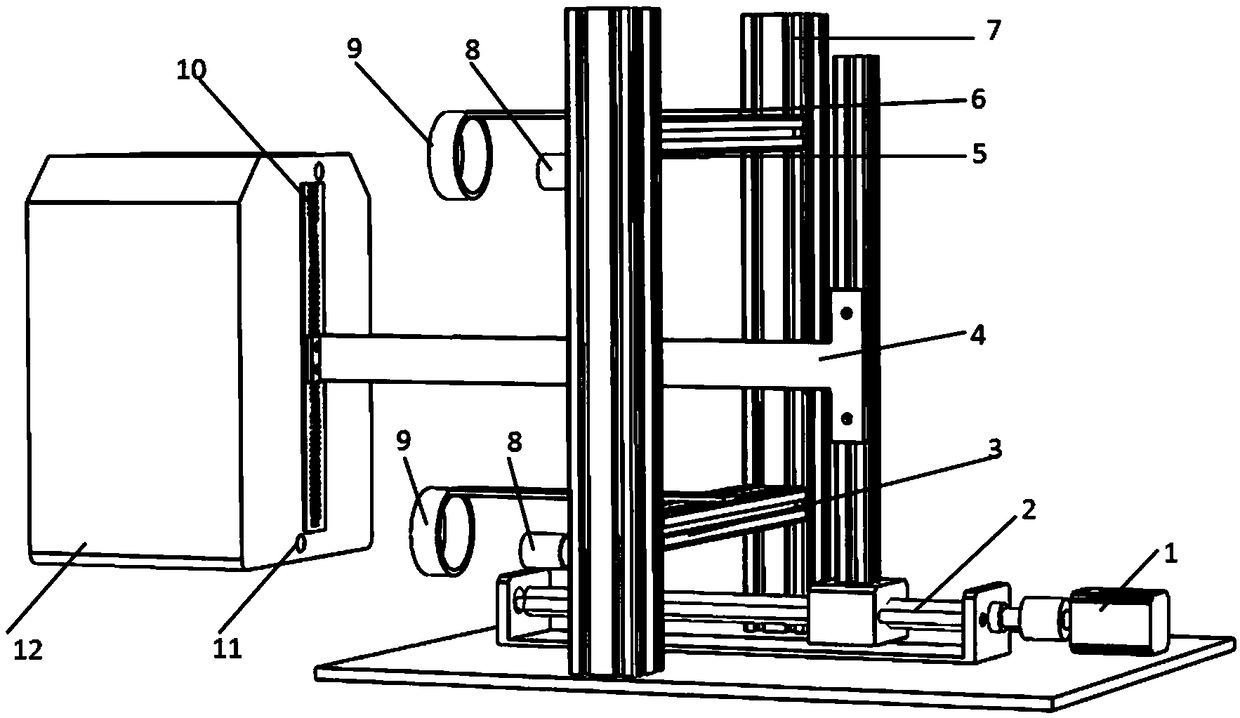

[0044] Such as figure 1 As shown, the specific implementation of the present invention includes a bottom plate, a checkerboard standard plate moving support part, a dual-camera image acquisition part and an image processing part.

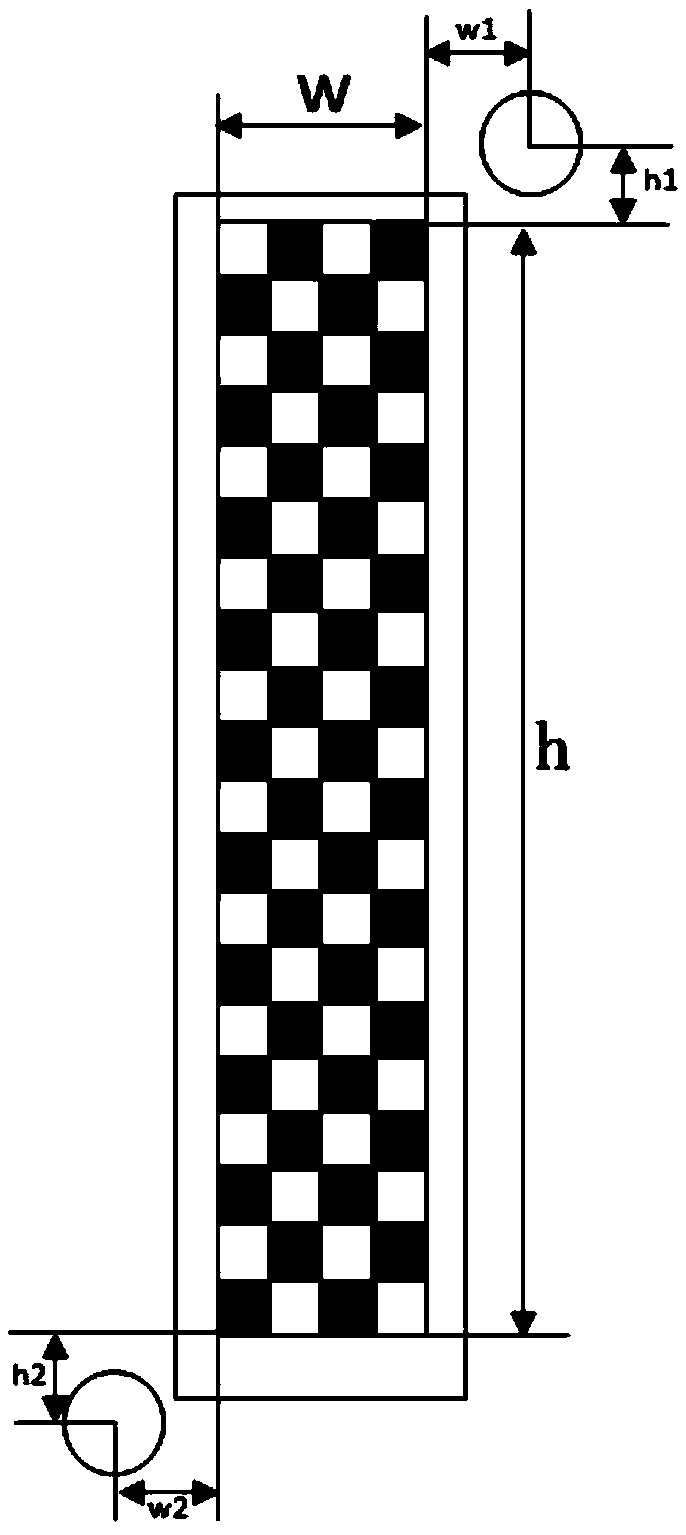

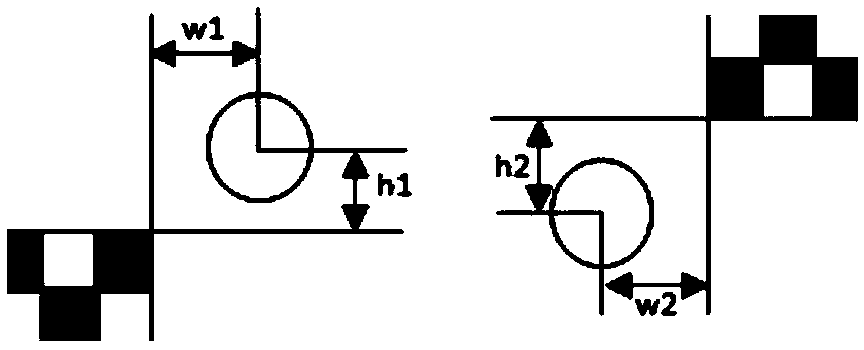

[0045]The mobile support part of the checkerboard standard board is used to support and move the checkerboard standard board 10, including the checkerboard standard board 10, the checkerboard support 4, the checkerboard mobile controller 1 and the guide rail 2; the guide rail 2 is fixed on the base plate and the guide rail 2 A checkerboard support 4 is fixed, and the checkerboard support 4 extends towards the end face of the tractor transmission box and is fixed with a checkerboard standard plate 10 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com