Method and device for checking the pre-installation of cutting rings on pipes

A cutting ring and pre-installation technology, which is applied in the field of pre-installation devices, can solve the problems that the cutting ring cannot ensure the quality of the workmanship and cannot realize complete inspection, and achieve the effect of a uniform light field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

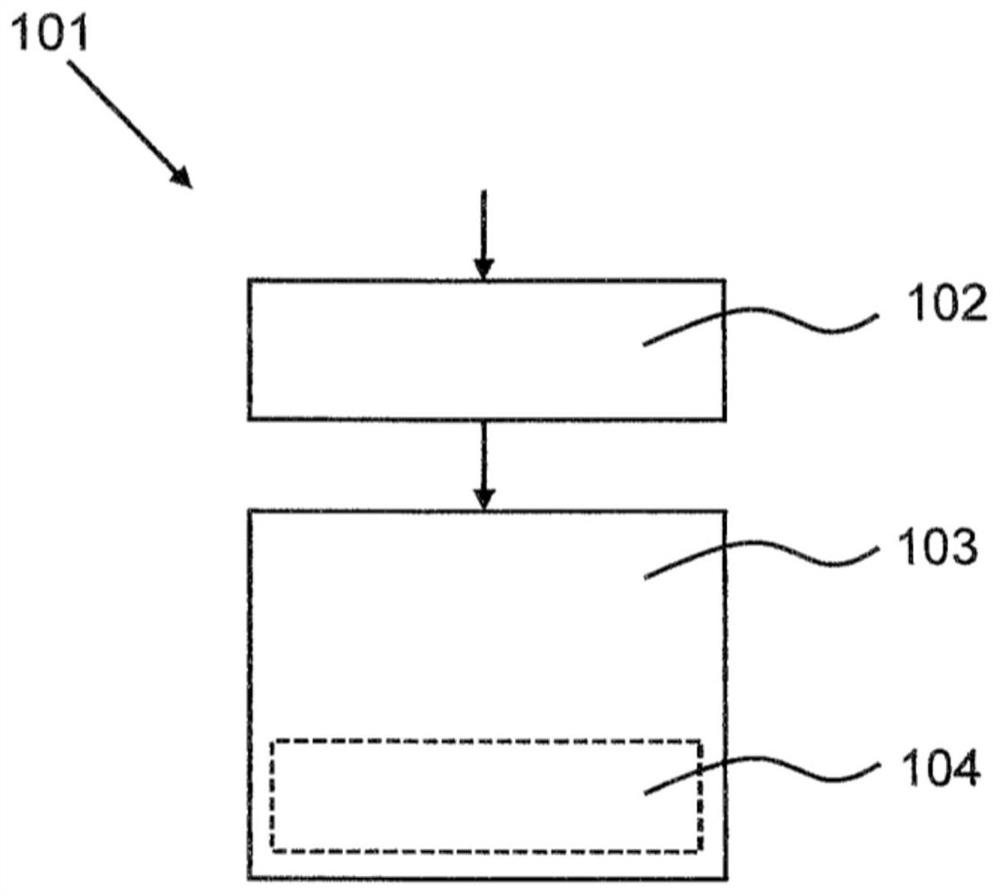

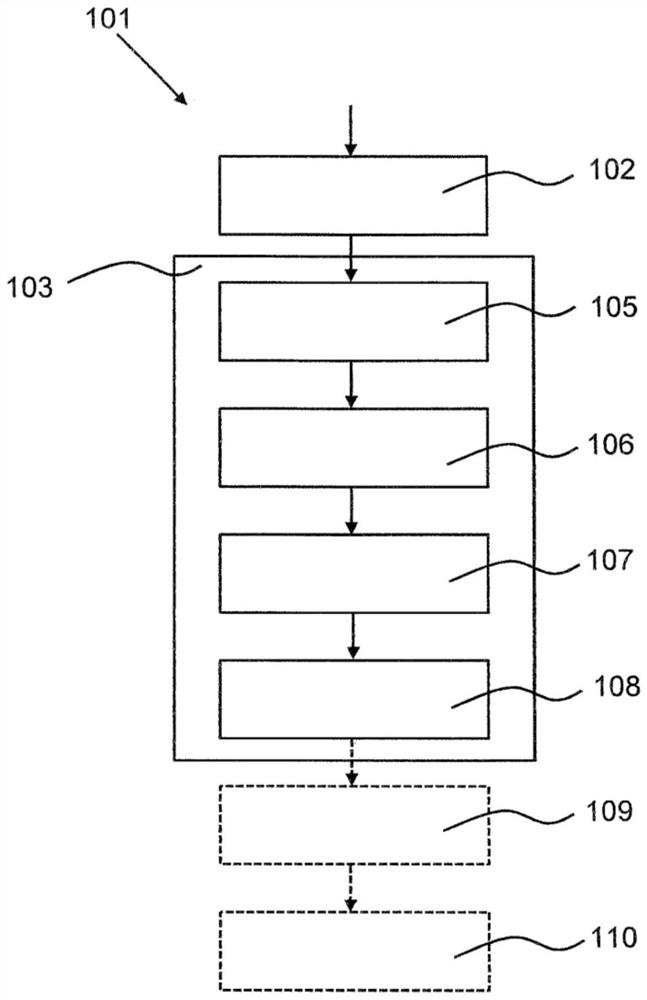

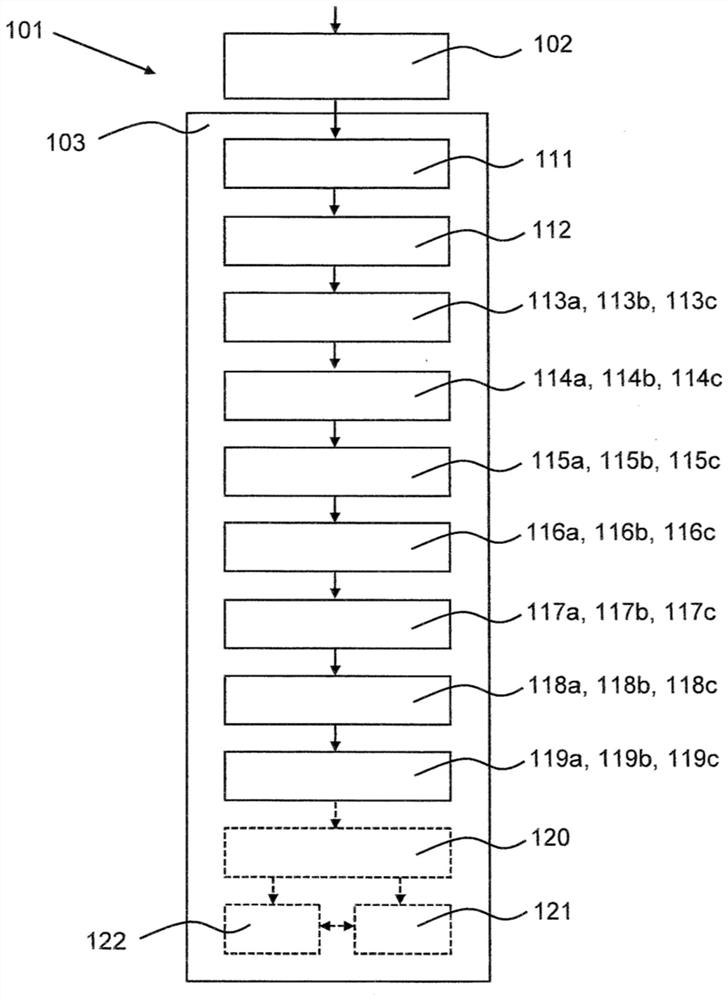

[0150] figure 1 shows an example for checking the Figure 4 The schematic process of an embodiment of the method 101 for the pre-installation of the cutting ring 1 on the pipe 2 is shown in FIG. Does it meet the requirements in order to achieve a sealed cutting ring screw joint (not shown) and the necessary tightening force for the pipe 2 . Method 101 is carried out with device 3 having at least one optical detection device 4 for detecting 102 image data in detection region 5 (see Figure 4 ).

[0151] according to figure 1 , the method 101 comprises at least the method steps described below, namely first detecting 102 at least first image data of the pipe 2 with the pre-mounted cutting ring 1 introduced at least partially into the detection region 5 . At least a part of the first image data is then evaluated 103 with respect to the position of the cutting ring 1 relative to the pipe 2 and / or the geometrical properties of the pipe 2 and / or the geometrical properties of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com