Structure adhesive steel-to-steel tensile shear strength sample preparation method

A shear strength and adhesive technology, applied in the preparation of test samples, etc., can solve the problems of complex tooling, inability to continuously prepare large quantities of samples, etc., and achieve the effect of simple and easy-to-obtain tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A component: 100 parts by weight of Baling Petrochemical 128, 10 parts of diluent 622;

[0034] Component B: 100 parts by weight of Beijing Jindao Qishi 04 curing agent.

[0035] Stir and mix components A and B in a weight ratio of 2:1 to make an adhesive.

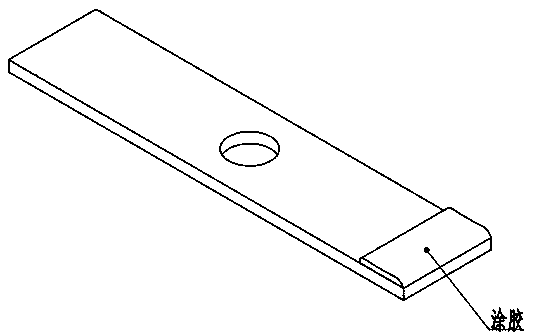

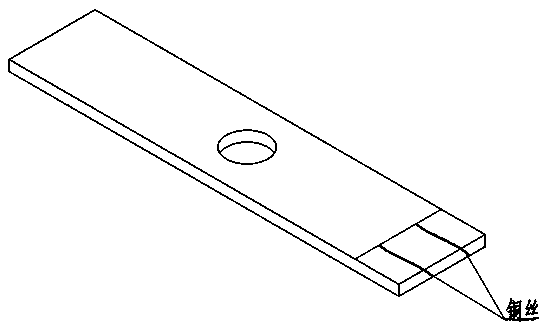

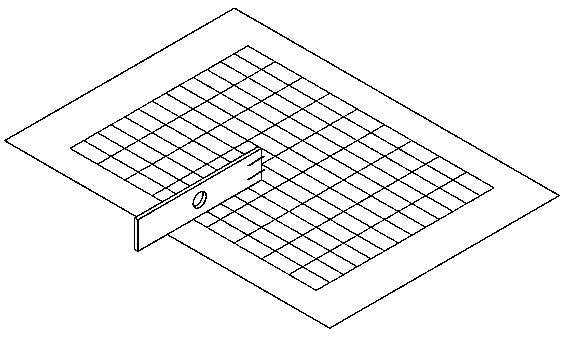

[0036] Wet the surface of the steel sheet after sand blasting, and then place a section of copper wire on one of the steel sheets parallel to the direction of the test piece, and the other steel sheet does not put copper wire, and the surface is treated with glue; Make sure that the horizontal board is placed horizontally; then place the form in turn, and the transparent plastic film should completely cover the form; on the transparent plastic film, fit the above two processes according to the cell size in the form For steel sheets with different treatments, when laminating, compare the cells in the table; then both steel sheets are vertical and aligned with the horizontal plate, and then use a clamping tool to cla...

Embodiment 2

[0038] A component: 100 parts by weight of Baling Petrochemical 128, 15 parts of diluent 622;

[0039] Component B: 100 parts by weight of Beijing Jindao Qishi 04 curing agent.

[0040] Stir and mix components A and B in a weight ratio of 2:1 to make an adhesive.

[0041] Wet the surface of the steel sheet after sand blasting, and then place a section of copper wire on one of the steel sheets parallel to the direction of the test piece, and the other steel sheet does not put copper wire, and the surface is treated with glue; Make sure that the horizontal board is placed horizontally; then place the form in turn, and the transparent plastic film should completely cover the form; on the transparent plastic film, fit the above two processes according to the cell size in the form For steel sheets with different treatments, when laminating, compare the cells in the table; then both steel sheets are vertical and aligned with the horizontal plate, and then use a clamping tool to cla...

Embodiment 3

[0043] Component A: 100 parts by weight of Baling Petrochemical 128, 20 parts of diluent 622;

[0044] Component B: 100 parts by weight of Beijing Jindao Qishi 04 curing agent.

[0045] Stir and mix components A and B in a weight ratio of 2:1 to make an adhesive.

[0046]Wet the surface of the steel sheet after sand blasting, and then place a section of copper wire on one of the steel sheets parallel to the direction of the test piece, and the other steel sheet does not put copper wire, and the surface is treated with glue; Make sure that the horizontal board is placed horizontally; then place the form in turn, and the transparent plastic film should completely cover the form; on the transparent plastic film, fit the above two processes according to the cell size in the form For steel sheets with different treatments, when laminating, compare the cells in the table; then both steel sheets are vertical and aligned with the horizontal plate, and then use a clamping tool to clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com