Test device and test method of shearing strength of UHPC-NC (Ultrahigh Performance Concrete-Normal Concrete) boning interface

A UHPC-NC, shear strength technology, applied in the field of testing, can solve the problems of large specimen size and difficult to control the normal stress accurately, and achieve the effect of clear force performance, strong repeatability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

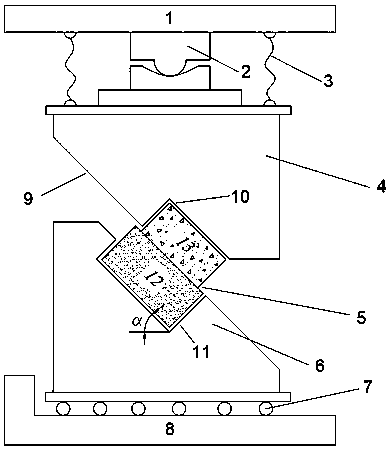

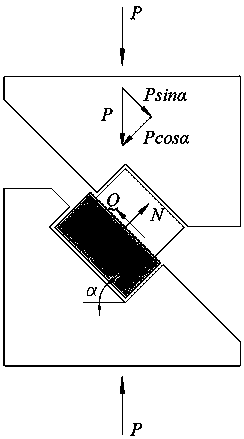

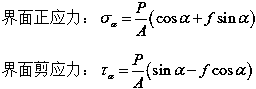

[0024] The invention relates to a method for testing the shear strength of the interface of a UHPC-NC laminated component. The test device includes: an upper testing machine press plate 1, an axial pressure device 2, an anti-drop steel wire rope 3, an upper steel fixture 4, and a UHPC- NC laminated specimen 5, lower steel fixture 6, steel roller 7, lower testing machine pressure plate 8. Wherein the laminated specimen 5 is formed by laminating prefabricated ultra-high performance concrete 12 and cast-in-place ordinary concrete 13 .

[0025] The components of the test device are assembled from bottom to top in the order of: lower testing machine platen→steel rollers→lower steel fixtures→laminated specimens→upper steel fixtures→axial pressure device→upper testing machine platen, The laminated test piece 5 is set between the first groove 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com