Hardness detection device for hardware manufacture

A detection device and function technology, applied in the field of hardness detection devices for hardware production, can solve the problems of slow detection speed, insufficient detection accuracy of detection equipment, troublesome operation of detection equipment, etc., and achieve the effect of convenient movement, dispersed gravity, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

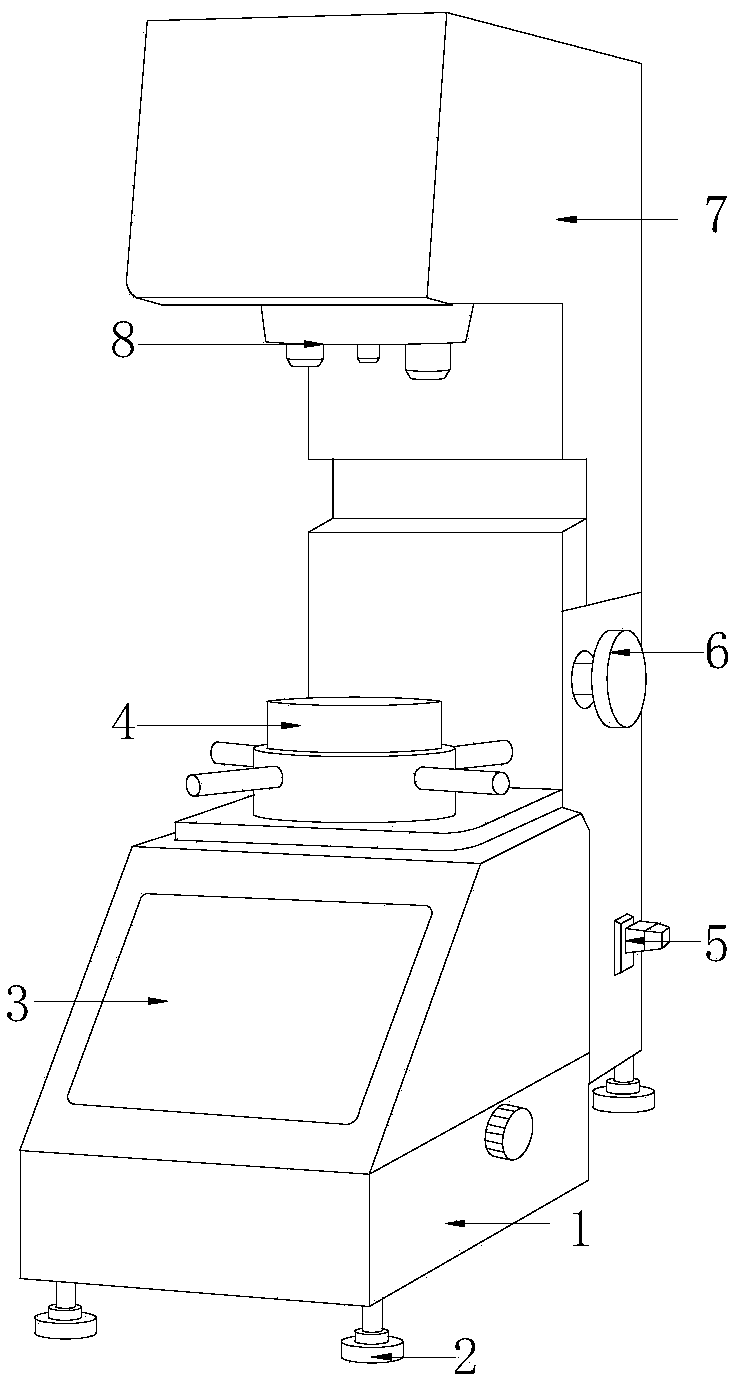

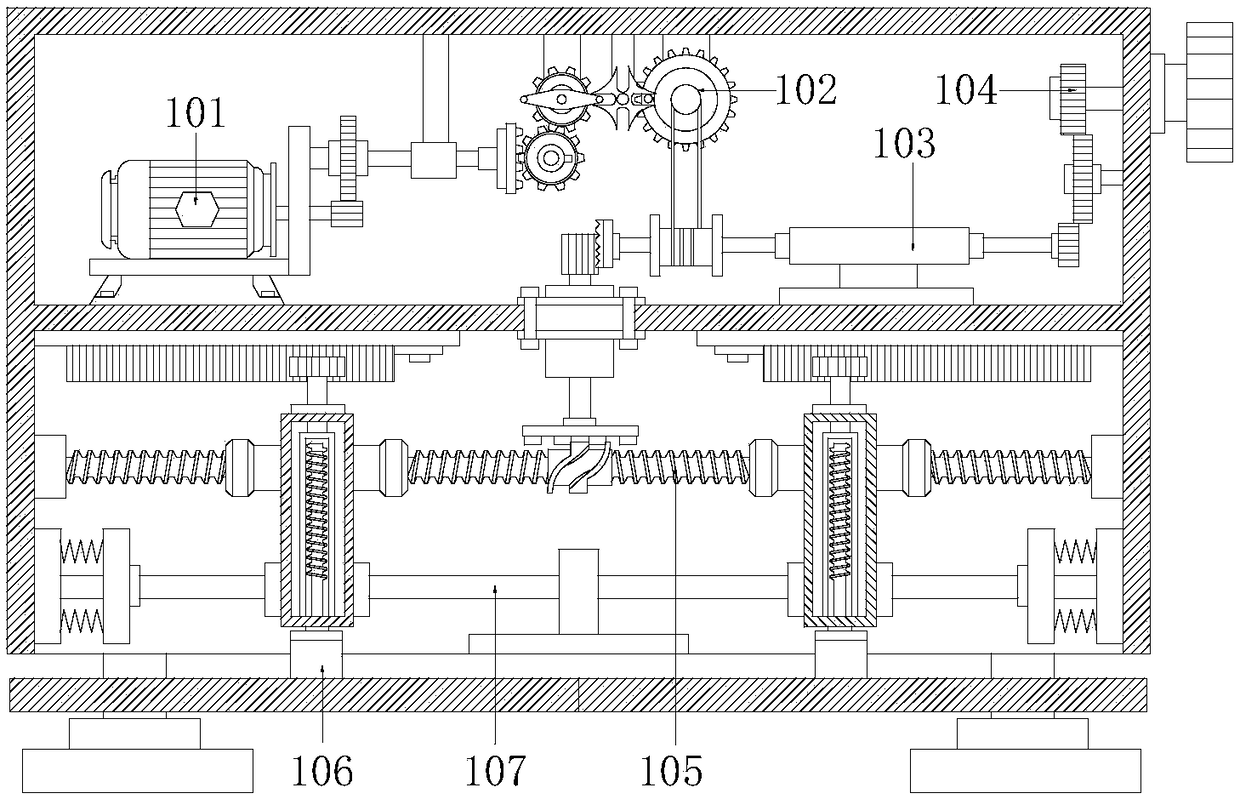

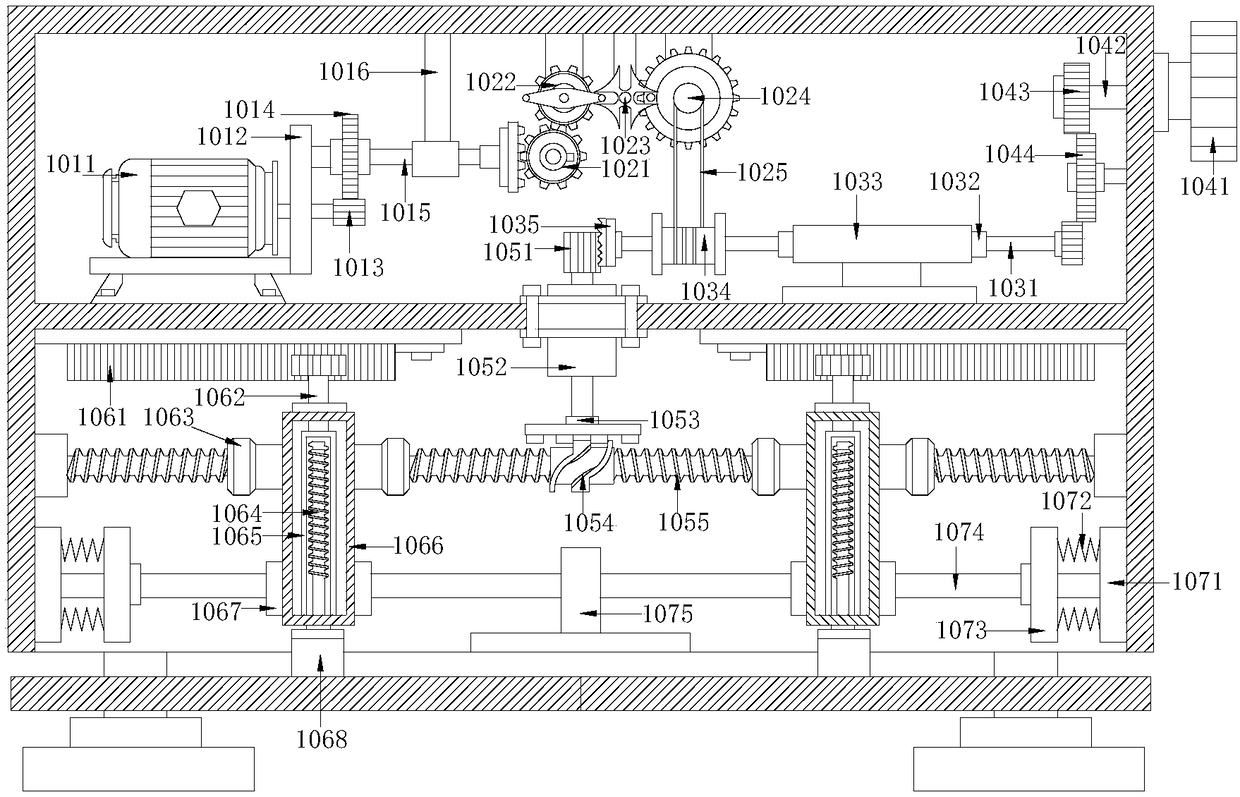

[0021] Such as Figure 1-Figure 4As shown, the present invention provides a hardware hardness testing device, the structure of which includes a support base 1, a foot pad 2, a control box 3, a chuck 4, a power connector 5, an adjustment knob 6, a body 7, and a detection head 8. The shell of the supporting base 1 is matched with the thread clearance on the top of the foot pad 2, and is close to the bottom of the control box 3, the chuck 4 is fixed on the top of the control box 3 by bolts, and the power connector 5 is horizontally nested in the Inside the groove on the right side of the body 7, the upper beam of the body 7 and the detection head 8 are fixed by screws, and are flexibly connected with the control box 3 at the bottom, and the adjustment knob 6 is horizontally fixed on the right side of the body 7, and mechanically connected , the support base 1 is provided with an adjustment motor 101, a gear set 102, a transmission gear rod 103, a fine adjustment knob 104, a later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com