Large-size liquid crystal display screen defect detecting method based on machine vision

A technology of defect detection and machine vision, which is applied in the direction of optical testing of defects/defects, instruments, measuring devices, etc., can solve the problems of being easily disturbed by the external environment, increasing production costs, and increasing the difficulty of large-size LCD screen detection, etc., to achieve good results. Universal applicability, to achieve the effect of defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

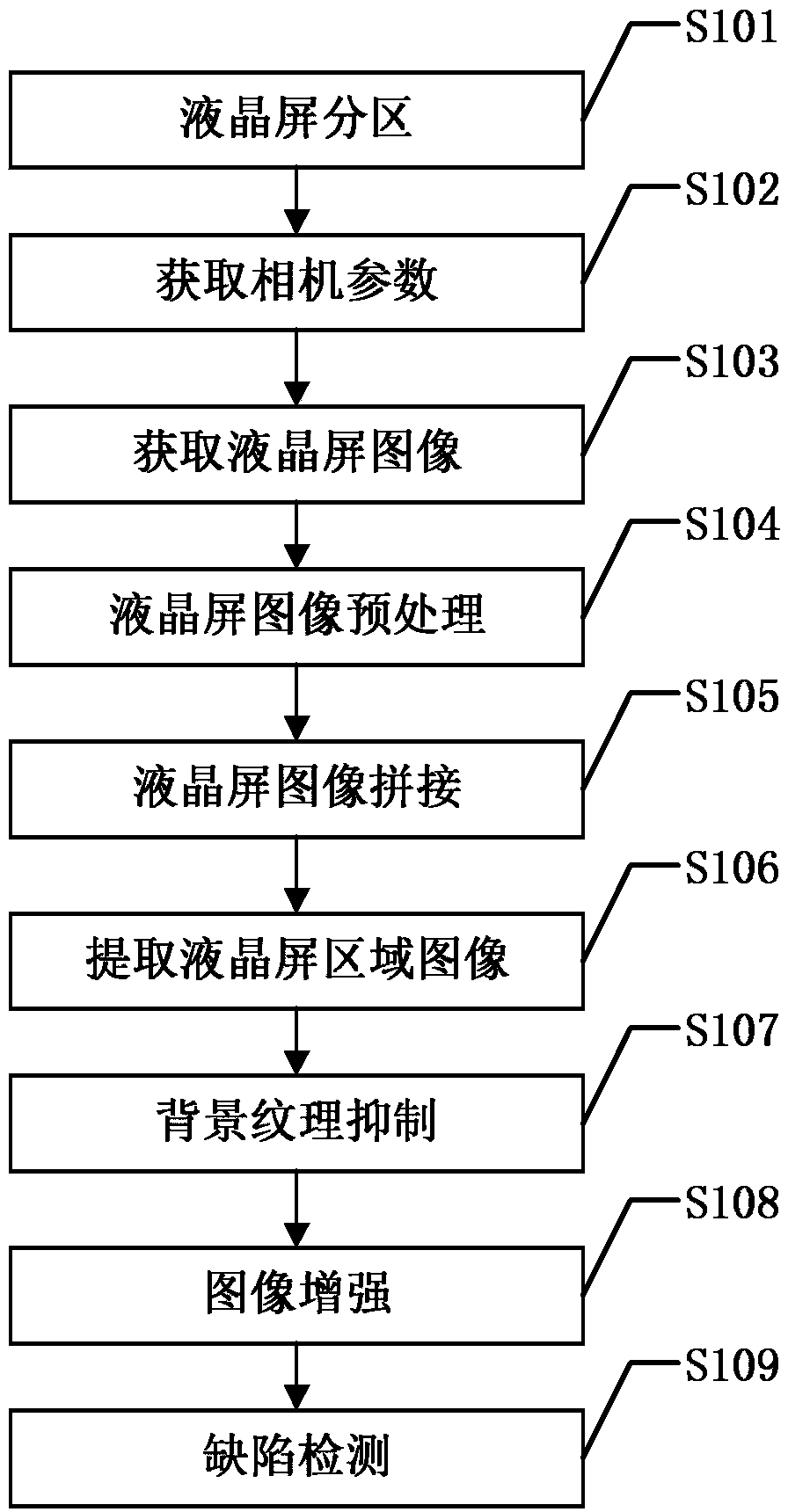

[0032] figure 1 It is a flowchart of a specific implementation of the method for detecting defects of large-size liquid crystal screens based on machine vision of the present invention. Such as figure 1 As shown, the machine vision-based defect detection method for large-size LCD screens of the present invention mainly includes two parts: a calibration part and a detection part. The calibration part is mainly to obtain the distortion parameters and distortion parameters of multiple cameras that shoot the LCD screen before detecting the LCD screen defects. The homography matrix is used for multi-image stitching in the subsequent inspection part. The inspection part is to detect the actual LCD screen defects. The specific steps of the machine vision-based defect detection method for large-size LCD screens of the present invention include:

[0033] S101: LCD screen partition:

[0034] Due to the large size of the large-size LCD screen, when machine vision is used for defect detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com