Cooling control apparatus for exposure table surface in exposure machine

A technology of cooling control and exposure machine, which is applied in the direction of photo-plate-making process exposure device, photo-plate-making process of pattern surface, optical mechanical equipment, etc., which can solve problems such as temperature unevenness, image PCB expansion and contraction, and board failure, and achieve Simple structure, improved PCB expansion and contraction, novel design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in conjunction with specific embodiments.

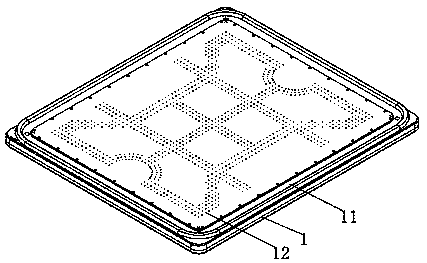

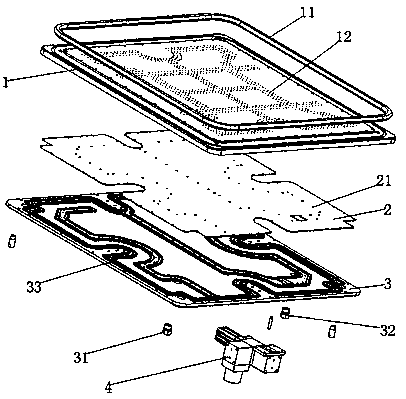

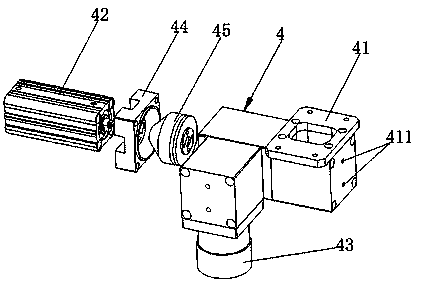

[0025] Such as Figure 1-3 As shown, a cooling control device applied to the exposure table in an exposure machine includes a middle frame 1, a middle frame sealing strip 11 is installed on the upper end of the middle frame 1, a heat dissipation plate 2 is installed on the lower end, and a heat dissipation plate 2 is installed on the lower end. There is a bottom plate 3, the lower end of the bottom plate 3 is equipped with a water inlet 31 and a water outlet 32, and the lower end of the bottom plate 3 is equipped with a device for controlling the positive and negative pressure between the cooling plate 2 and the middle frame 1 and part of the water vapor attached to the cooling plate 2 The gas-liquid splitting device 4, the gas-liquid splitting device 4 is provided with a switcher 41 installed at the lower end of the base plate 3, the switcher 41 is connected with a cylinder 42 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com