Calculation method for plant cavitation factor of through-flow turbine

A tubular turbine and cavitation coefficient technology, which is applied in the directions of calculation, electrical digital data processing, design optimization/simulation, etc., can solve the problem that the cavitation coefficient cannot be selected correctly, the power station cavitation coefficient is difficult to meet the new hydropower engineering requirements, and the results are different, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

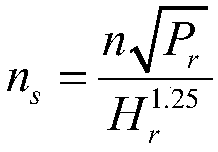

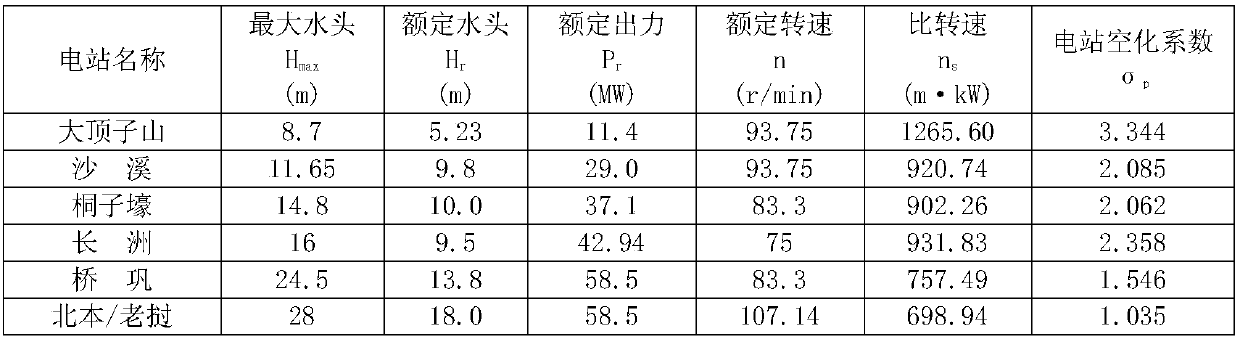

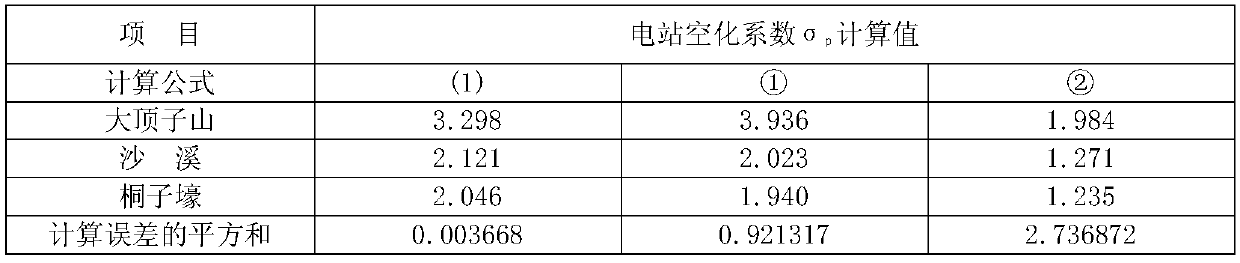

[0013] The present invention first collects and organizes the data of a large number of domestic and foreign well-running tubular water turbine generating sets in the past 30 years, according to the maximum application water head H of the water turbine. max , divide the data into H max ≤15m and H max For two groups > 15m, the least square method is used to use a large number of turbine parameters as sample data, and regression statistics are used to obtain the cavitation coefficient σ of the hydropower station at the two water head sections p Calculation formula: when H max ≤15m, σ p =3.7004×ln(n s )-23.135(1); when H max >15m, σ p =3.6575×ln(n s )-22.84(2), after doing a lot of calculation and derivation work in the early stage, a more reasonable calculation method was creatively summarized for the cavitation coefficient of the tubular hydro turbine power station. Since the present invention will H max The range is divided, so the tubular turbines corresponding to dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com