A step-by-step composite lithium-rich oxide solid solution material and preparation method thereof

An oxide solid solution and material technology, applied in electrochemical generators, structural parts, electrical components, etc., can solve the problems of poor material cycle performance and limited wide application, achieve high specific capacity, improve cycle performance, and inhibit structural damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

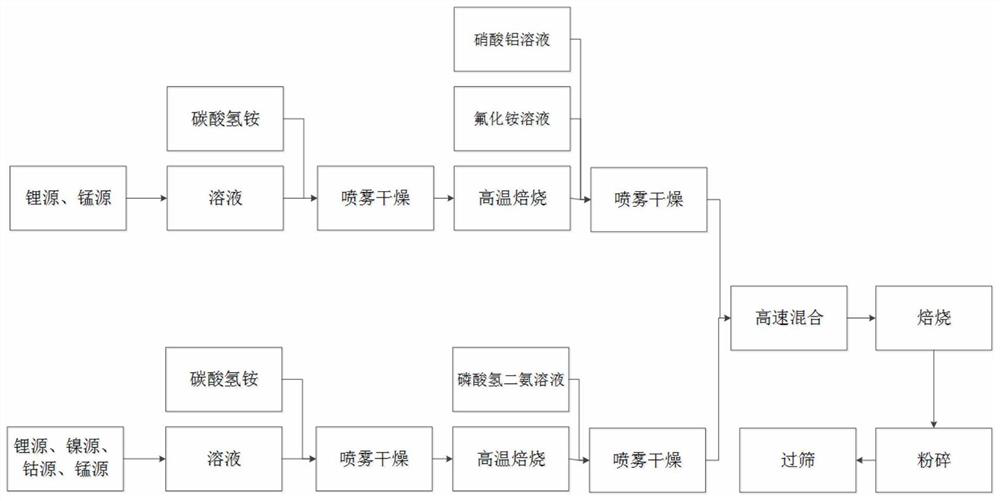

Method used

Image

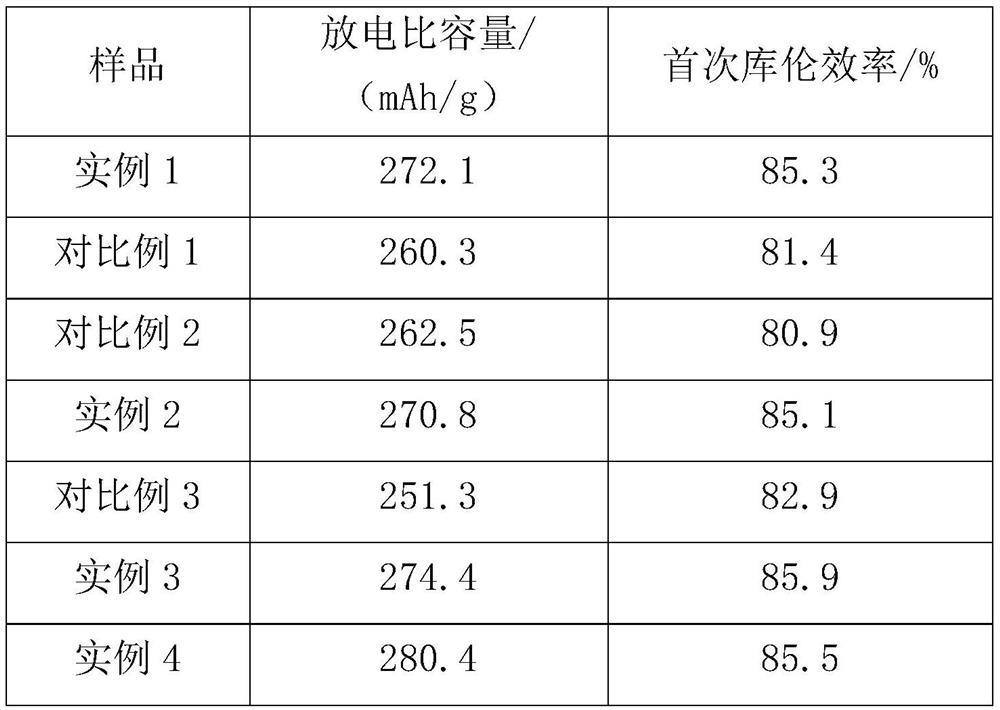

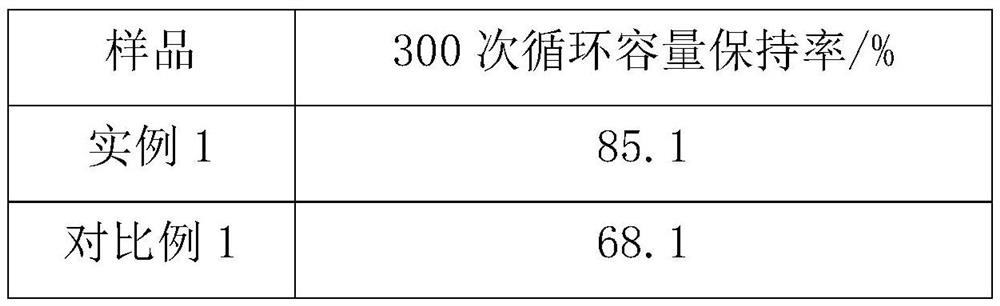

Examples

Embodiment 1

[0033] A step-by-step composite lithium-rich oxide solid solution material and a preparation method thereof, comprising the following steps:

[0034] 1) Lithium nitrate and manganese nitrate were dissolved in deionized water to obtain solution I, wherein the amount of manganese substance was 10mol, and the amount of lithium substance / manganese substance=2:1;

[0035] 2) Add ammonium bicarbonate dropwise to the solution I for 8 hours to obtain a solid-liquid mixture II, wherein the amount of ammonium bicarbonate substance / amount of manganese substance=1.5;

[0036] 3) Spray drying the solid-liquid mixture II at a temperature of 200° C. to obtain material III;

[0037] 4) roasting the material III in an air atmosphere, the roasting temperature is 750° C., and the roasting time is 16 hours to obtain the material IV, the amount of the material IV=the amount of manganese in step 1);

[0038] 5) The material IV was added to deionized water, and the aluminum nitrate solution and the...

Embodiment 1

[0049] Embodiment 1 is modified as follows:

[0050] 11) The material X was added to deionized water, and the aluminum nitrate solution and the ammonium fluoride solution were added dropwise thereto for 4 hours to obtain a solid-liquid mixture XI, wherein the amount of fluorine substance / aluminum substance = 3:1 , the amount of material X substance / aluminum substance=100:0.5;

[0051] 12) Spray drying the material Ⅺ at a temperature of 200° C. to obtain material Ⅻ, which is a ternary layered material coated with aluminum fluoride phosphate;

[0052] The rest of the steps are the same. The final product obtained is a lithium-rich oxide solid solution material coated with aluminum fluoride, and the main molecular formula of the product is 0.5Li 2 MnO 3 0.5LiNi 0.5 co 0.2 mn 0.3 o 2 .

Embodiment 1

[0059] Embodiment 1 is modified as follows:

[0060] 5) Add the material IV into deionized water, add aluminum nitrate solution and ammonium fluoride solution dropwise therein for 6 hours, add diammonium hydrogen phosphate solution dropwise therein for 4 hours, and obtain a solid-liquid mixture V, Wherein the amount of fluorine substance / aluminum substance=3:1, the amount of material IV substance / aluminum substance=100:1, the amount of material IV substance / phosphate root substance=100:1;

[0061] 6) Spray-dry the solid-liquid mixture V at a temperature of 260° C. to obtain material VI, which is aluminum fluoride phosphate-coated Li 2 MnO 3 Material;

[0062] 11) Add the material X into deionized water, add diammonium hydrogen phosphate solution dropwise for 4 hours, add aluminum nitrate solution and ammonium fluoride solution dropwise for 6 hours at the same time, and obtain a solid-liquid mixed material Ⅺ, wherein the amount of material X substance / amount of phosphate rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com