Projection display based galvanometer automatic synchronization system and method

An automatic synchronization, projection display technology, applied in the field of projection display technology, can solve the problem of inaccurate adjustment of the galvanometer and image frame sequence synchronization, and achieve the effect of accurate synchronization adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The technical scheme of the present invention will be described in detail below with examples.

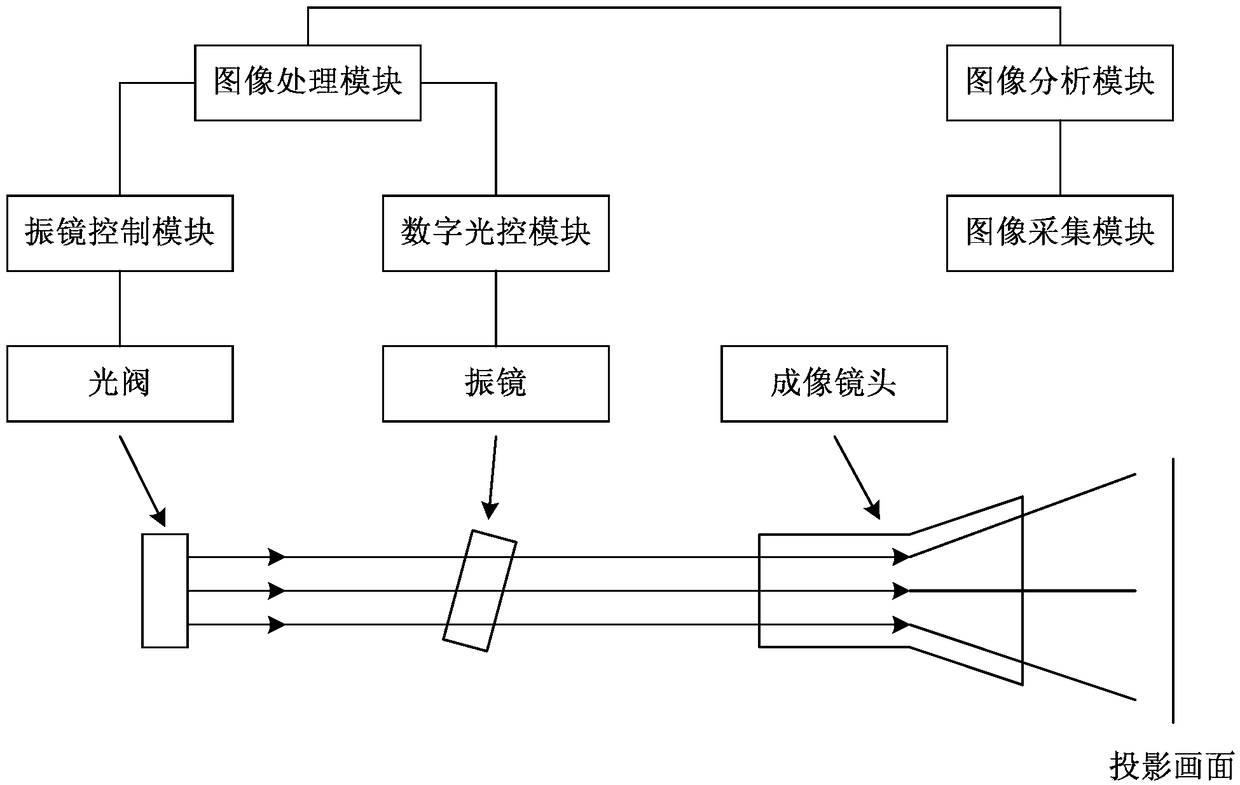

[0067] Such as figure 1 As shown, the hardware system of this example includes an image processing module, a digital light control module, a light valve, a galvanometer control module, a galvanometer, an imaging lens, an image acquisition module, and an image analysis module. The module is connected with the light valve, the vibrating mirror control module is respectively connected with the image processing module and the vibrating mirror, and the image analysis module is respectively connected with the image acquisition module and the image processing module.

[0068] When using it, you need to preset the test picture in the system first. The test picture in this example contains multiple test images with independent areas, and each test image is grayscaled and normalized separately and saved. What is obtained is the standard image corresponding to each test image.

[006...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap