Full-automatic aluminum bar hot shearing machine

A hot shearing machine, fully automatic technology, applied in shearing machine equipment, shearing devices, accessories of shearing machines, etc., can solve the problems of large fracture deformation of aluminum rods, affecting production scheduling and yield, and rising production costs. To achieve the effect of good profile surface quality, convenient and fast automation, and small fracture deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

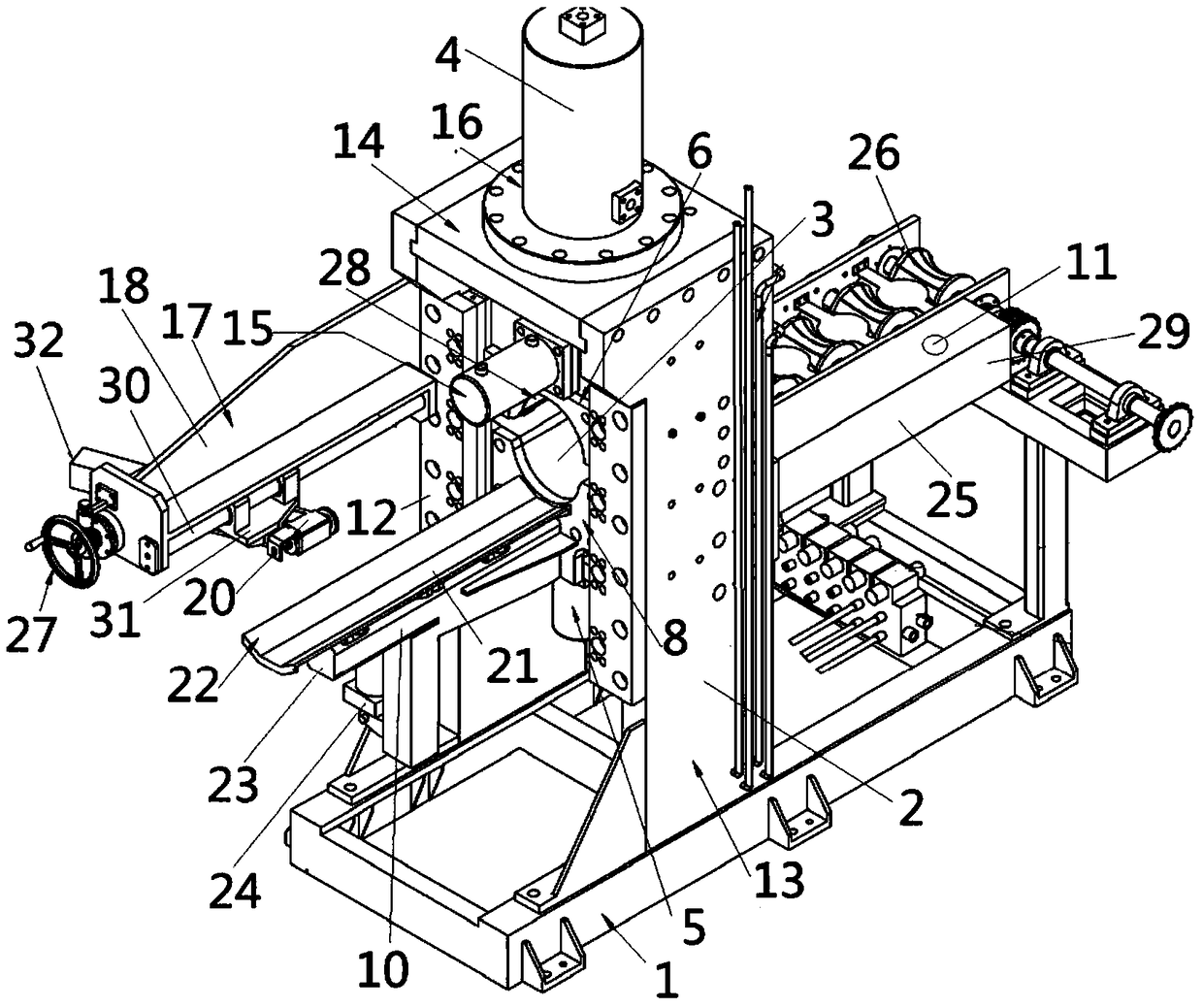

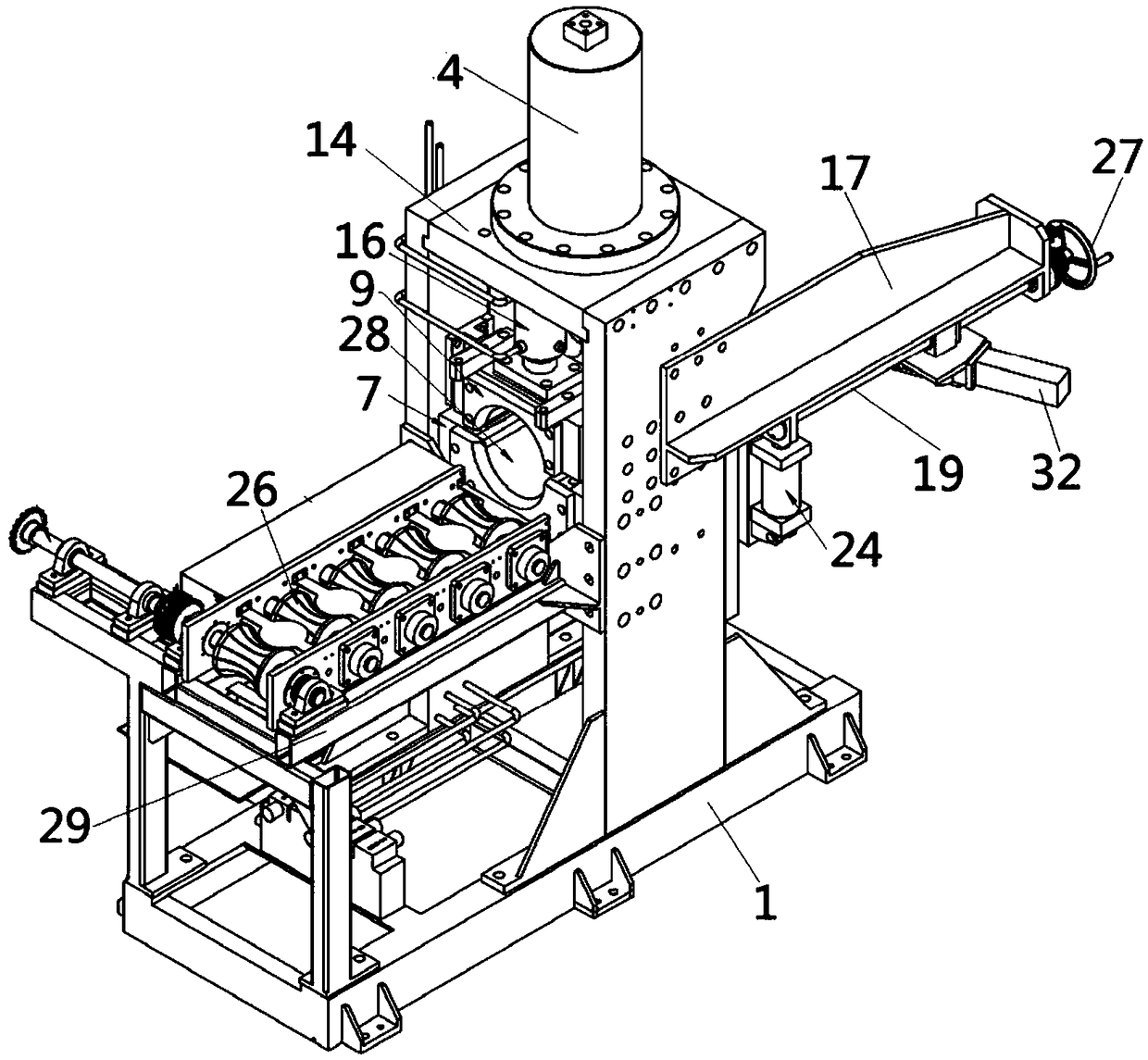

[0029] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0030] as attached figure 1 , attached figure 2 As shown, the present invention is a fully automatic aluminum rod hot shearing machine. The automatic aluminum rod hot shearing machine includes a hot shearing machine base 1. A processing frame 2 is arranged on the hot shearing machine base 1. The processing frame 2 The aluminum rod channel 3 is arranged on the top, the main oil cylinder 4 is arranged on the top plate 14 above the aluminum rod channel 3, the movable knife seat 6 is connected with the main oil cylinder 4, a scissor blade 28 is installed on the movable knife seat 6, and the processing frame below the alu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap