Edge cutting device for production of sun-shading roller shutter

A sunshade roller blind and edge cutting technology, which is applied in metal processing and other directions, can solve the problems that the cloth is easy to be trampled and dirty, and the cutting width cannot be adjusted, so as to achieve the effect of shortening the working time, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

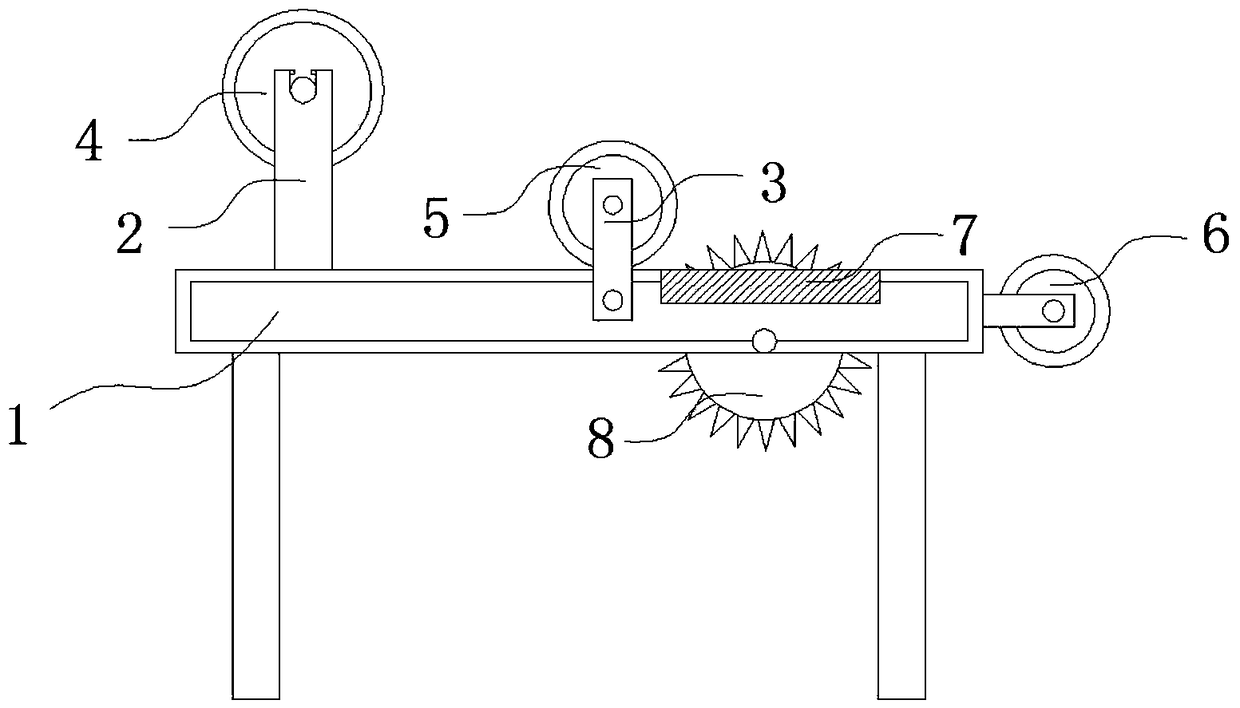

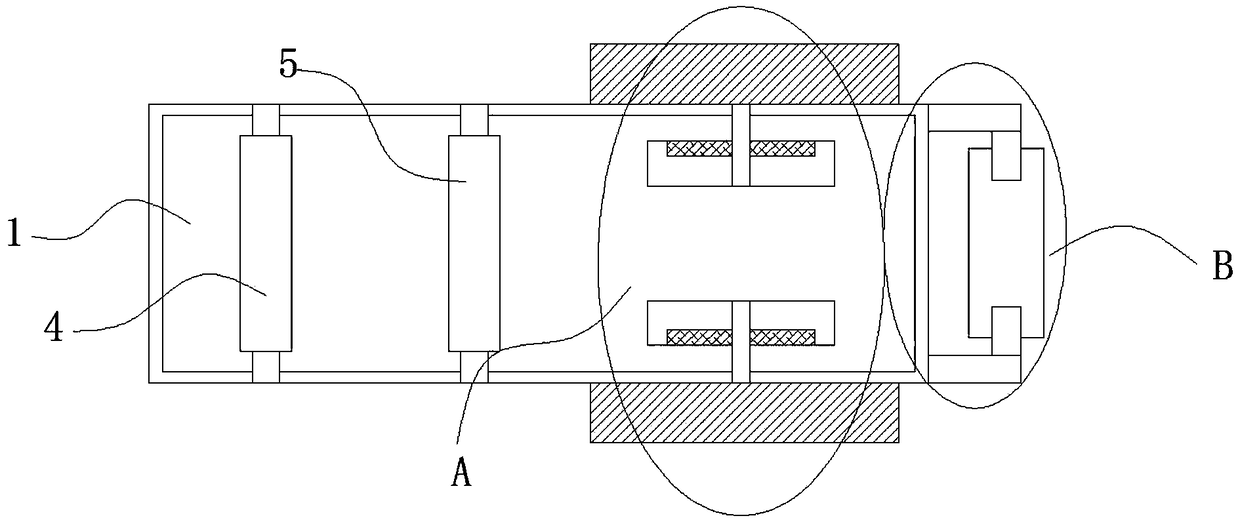

Embodiment 1

[0027] Embodiment 1, insert the roller shaft in the middle of the roller blind roller 4 that needs to be cut, and hang it in the groove of the installation pole 2. The shaft 11 moves into the side support rod 9 (the insertion shaft 11 can move with the rotating handle 12, and the part of the side support rod 9 is positioned at the side of the insertion shaft 11 is opened), and then another person plugs one end of the winding roller 6 into the second position. Place the rewinding roller 6 flat on a rotating shaft 10, and then push the rotating handle 12 to insert the insertion shaft 11 into the other side of the rewinding roller 6. When the bullet 14 moves to the empty hole 13 with the push of the rotating handle 12 , ejected under the elastic action of the spring on one side, at this time, the turning handle 12 is no longer pushed, and the insertion shaft 11 is also inserted into the inside of the winding roller 6, the trimming wheel 8 is started, and then the roller blind roll...

Embodiment 2

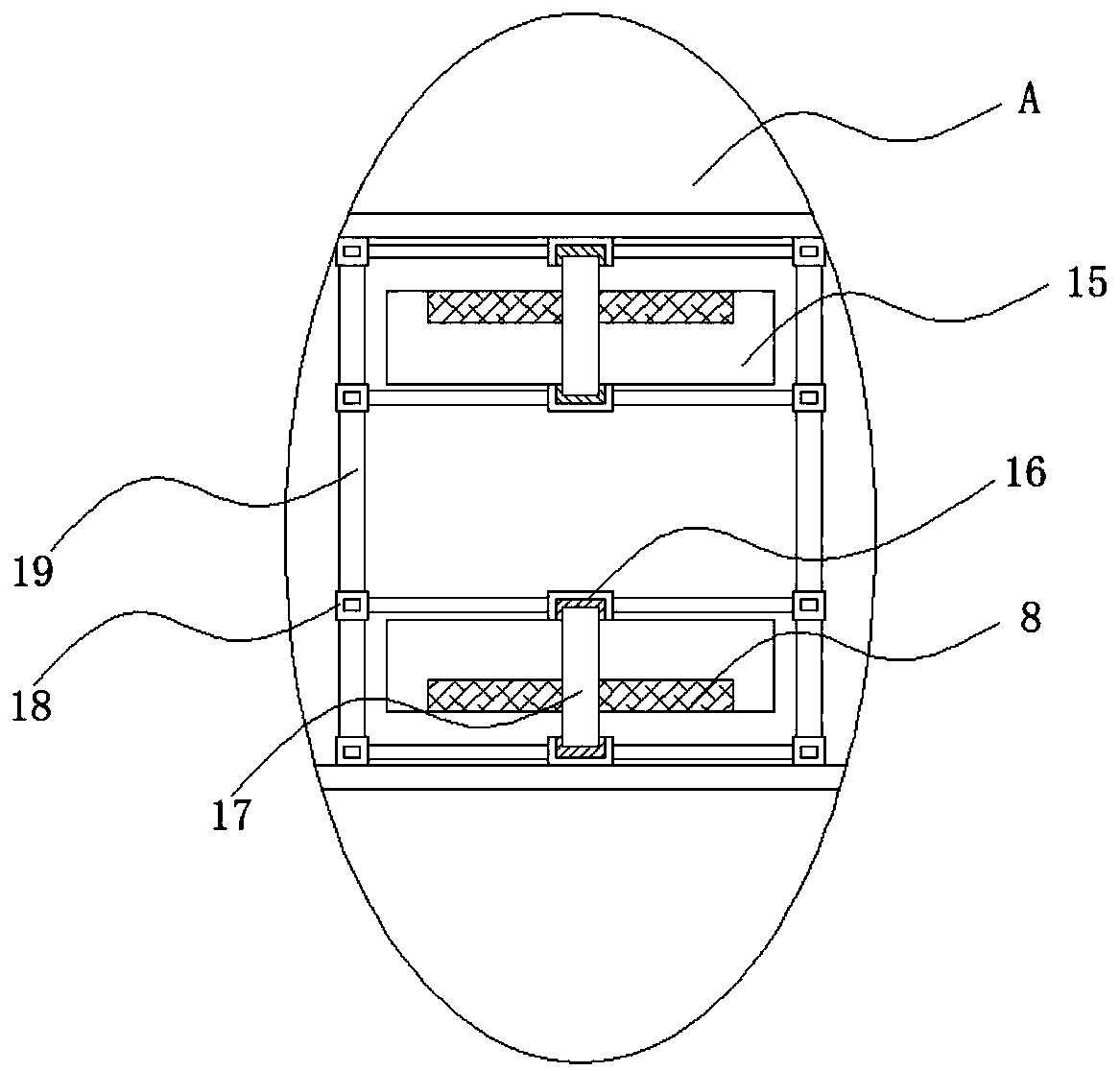

[0028]Embodiment 2, when it is necessary to cut roller blind sides of different widths, manually use a ruler to measure the distance from the width to one side of the workbench, then unscrew the locking block on the movable block 18, put on gloves and hold the second rotating shaft 17 Move back and forth between the wheel holes 15, so that the trimming wheel 8 moves to the measured distance to stop, insert the locking block and tighten it, and then adjust the position of the trimming wheel 8 on the other side in the same way. Insert the locking block and tighten to fix it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com