Oil drum nozzle in-mold forming robot

An in-mold forming and robotic technology, applied in household components, household appliances, other household appliances, etc., can solve problems such as low work efficiency, save labor, improve efficiency, and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

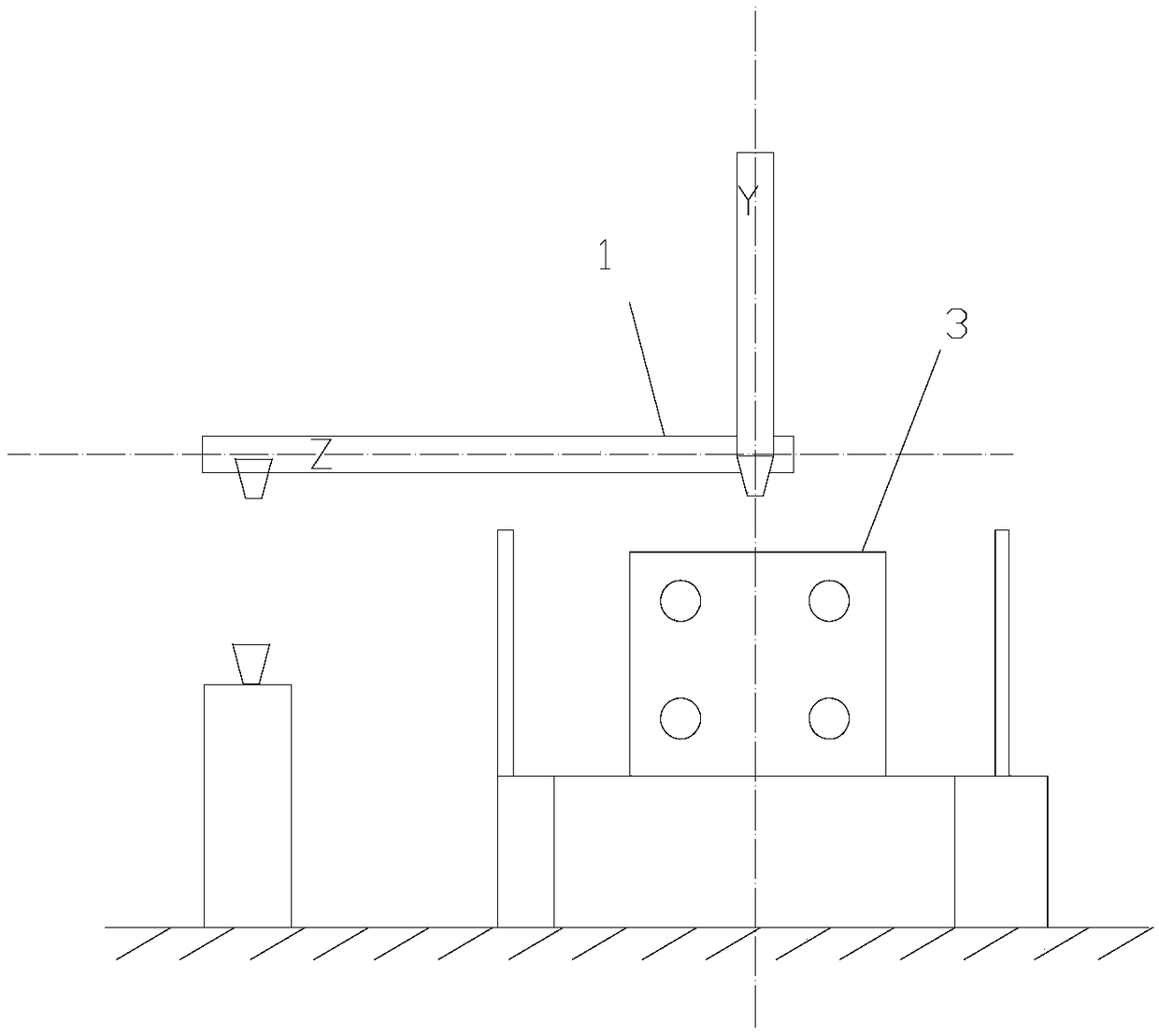

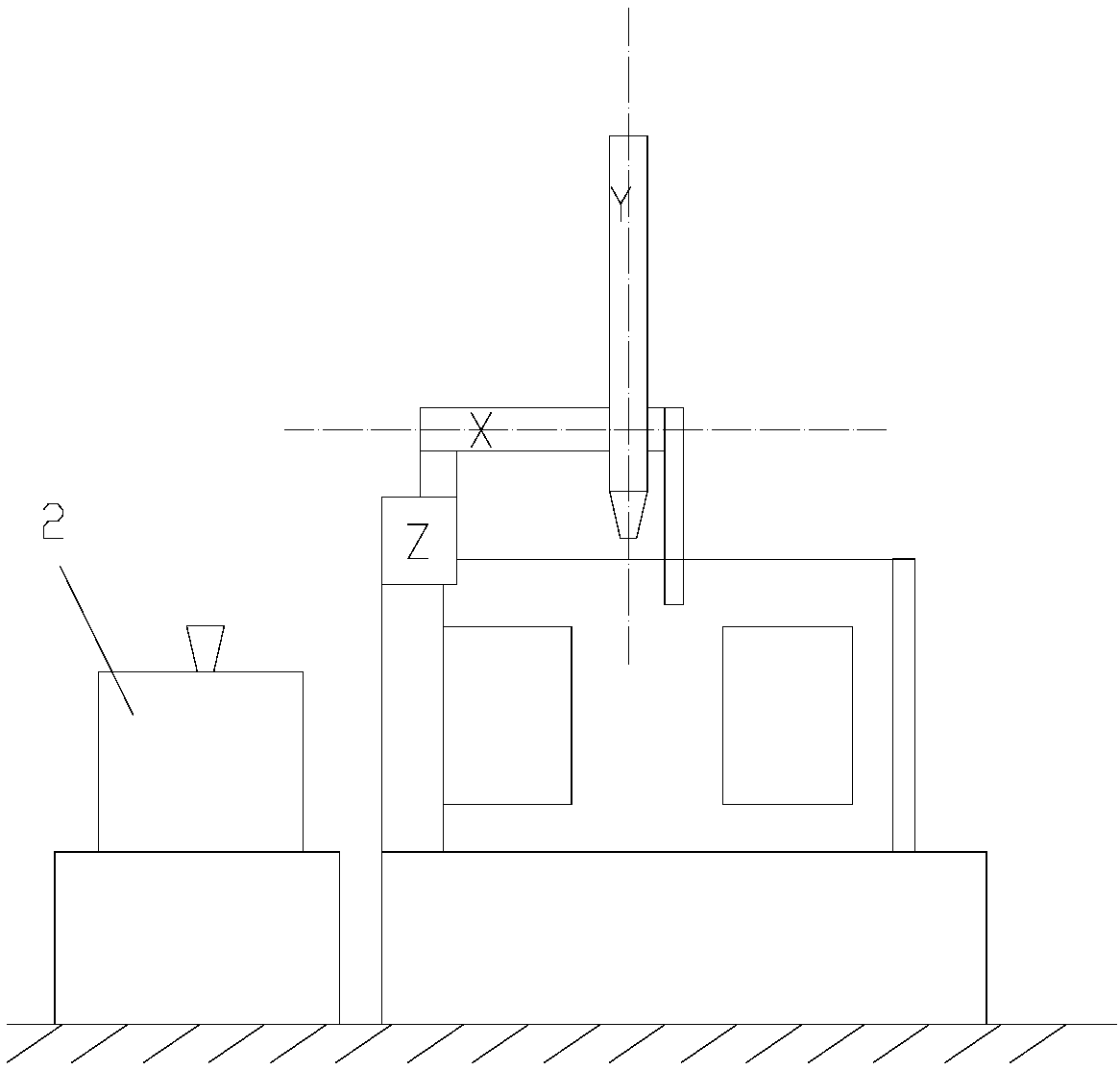

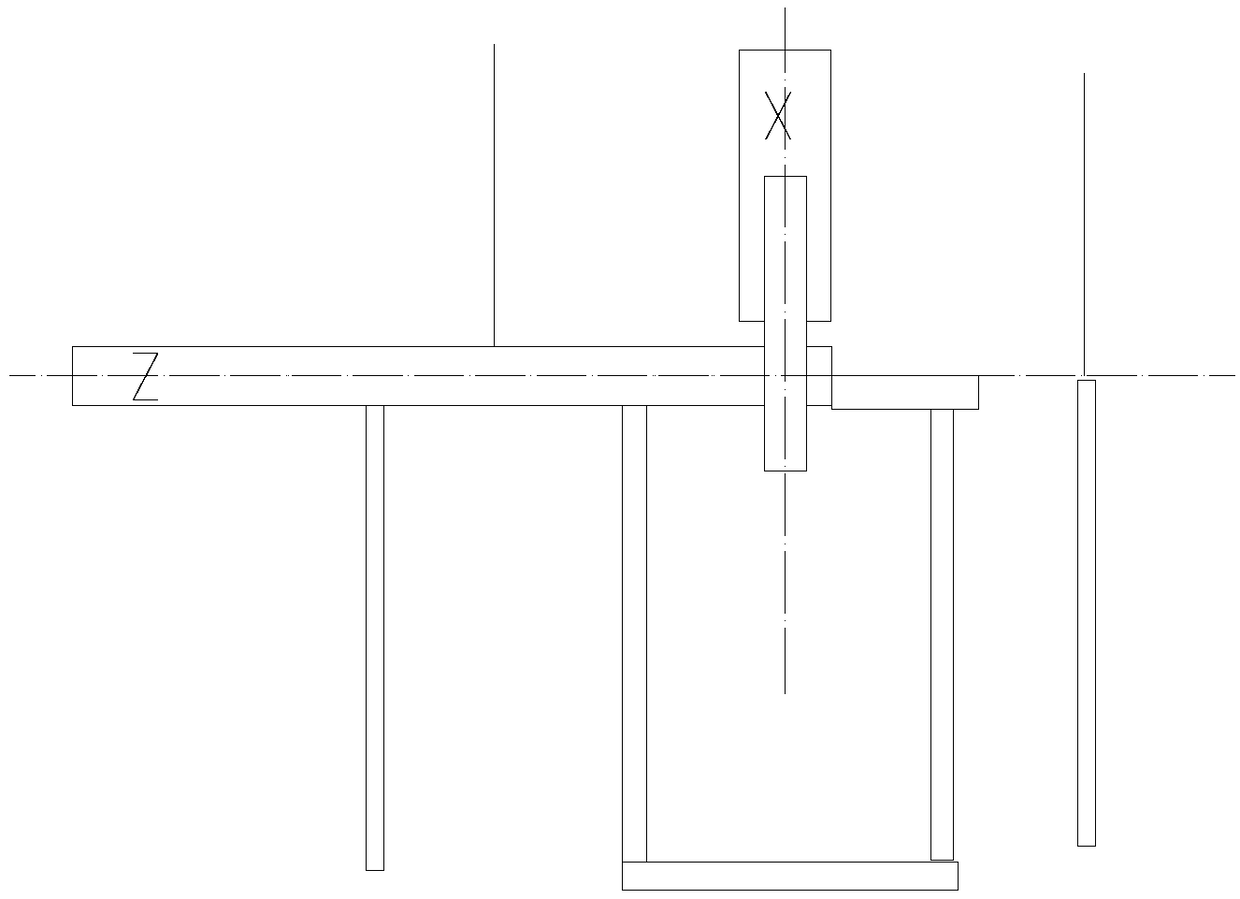

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1-3 As shown, a kind of in-mold molding robot for oil barrel and oil nozzle includes a six-axis manipulator 1, an automatic vibrating plate conveyor 2 and an injection molding machine 3 for injection molding lids; the six-axis manipulator is arranged on one of the two templates of the injection molding machine side, the vibrating plate automatic conveyor is set on one side of the injection molding machine, and the six-axis manipulator takes the oil nozzle from the vibrating plate automatic conveyor and sends it to the place where the oil nozzle needs to be placed between the two template molds of the injection molding machine. Location. The vibrating plate automatic conveyor uses vibration to place the oil nozzles and transport them in a unified direction. With positioning and sensing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com