Automobile interior light-emitting ceiling and production method thereof

A technology for automotive interiors and production methods, applied in the optical aspects of lighting equipment, light guides, vehicle parts, etc., can solve problems such as mass production unsuitable for industrialization, damage to accessories, monotonous patterns, etc., to improve flexibility and decorativeness. , Reduce material requirements, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

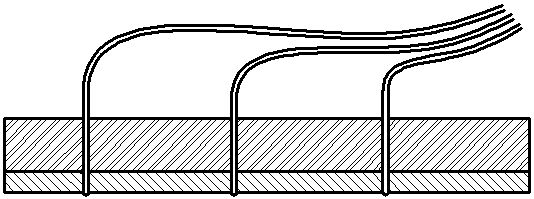

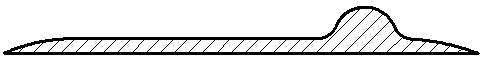

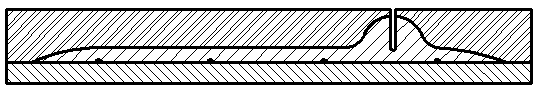

[0040] The automotive interior lighting ceiling structure of the present application is as follows: figure 2 or image 3 As shown, a light guide plate is embedded in the skeleton of the ceiling, and the surface of the skeleton is kept flat, and the surface of the skeleton is covered with fabric. The front side of the light guide plate is provided with a light outlet, the back side is provided with a light inlet, and the ceiling frame corresponding to the light inlet is provided with a gap. The light enters the light guide plate from the light entrance, and is reflected and transmitted in the light guide plate for many times. When it encounters the light exit, it is irradiated, and the light exit becomes a light-emitting point, realizing the effect of a starry sky ceiling.

[0041] In order to make the matching between the light guide plate and the ceiling frame easier, and to avoid gaps or drops between the edge of the light guide plate and the ceiling frame, which will affe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com