Textile rack convenient to adjust

A textile rack, a convenient technology, applied in the direction of textile, loom, textile and paper making, etc., can solve the problems of difficult adjustment of flatness, large noise of textile rack, etc., to achieve easy adjustment of level, improve work efficiency, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

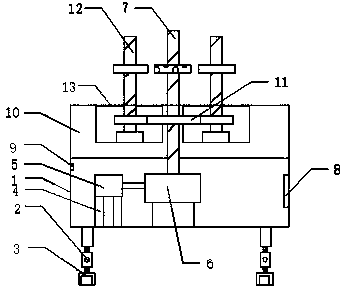

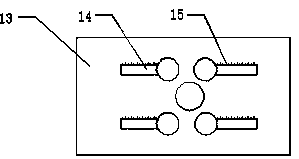

[0017] like Figure 1-2 As shown, a conveniently adjustable textile frame includes a support frame 1, a support platform 2 is provided at one end of the top of the support frame 1, and the support platform 2 mainly plays a supporting role as a whole. The side is connected to the base 4. The base 4 is mainly used to place the aluminum alloy parts to be processed. One end of the bottom of the base 4 is connected to the side of the support frame 1 through the first hydraulic device 5. The first hydraulic device 5 changes the inclination angle of the base 4 by stretching. 4. One end of the top is connected to the clamping device 6. During the placement and cutting process, the processed parts are cheap, resulting in a decrease in processing accuracy. One side of the clamping device 6 is provided with a fixed slide rail 7, and the top of the fixed slide rail 7 is connected to the scale scale 8, and the fixed slide rail 7 One side of the bolt is connected to the positioning rod 9, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com