Prefabricated wallboard and construction method thereof

A prefabricated assembly, wall panel technology, applied in building components, buildings, building structures, etc., can solve problems such as easy displacement and unstable connection, and achieve the effect of avoiding bursting, ensuring strength, and strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

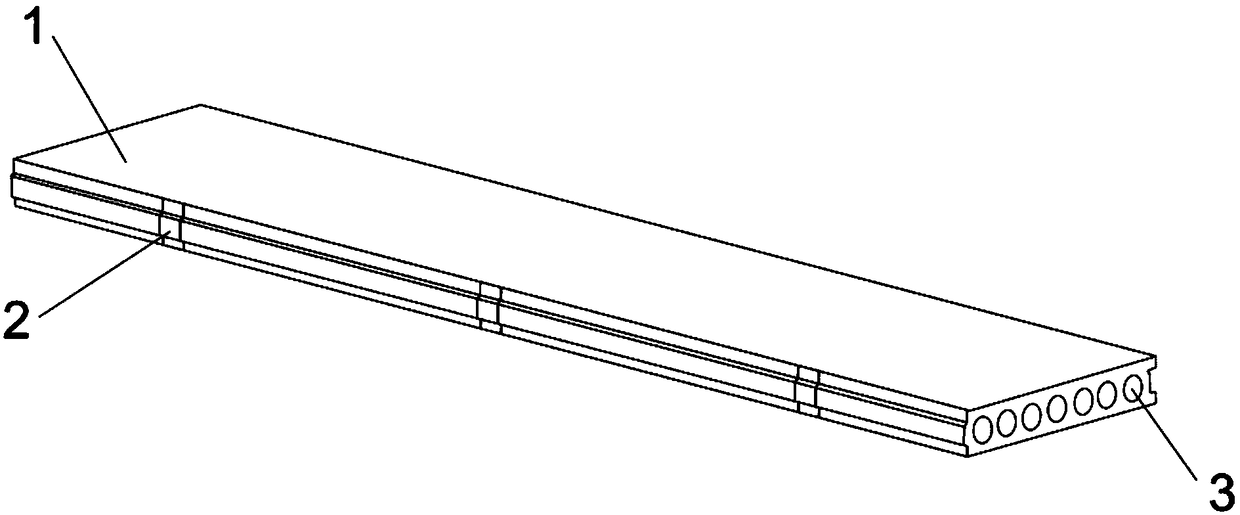

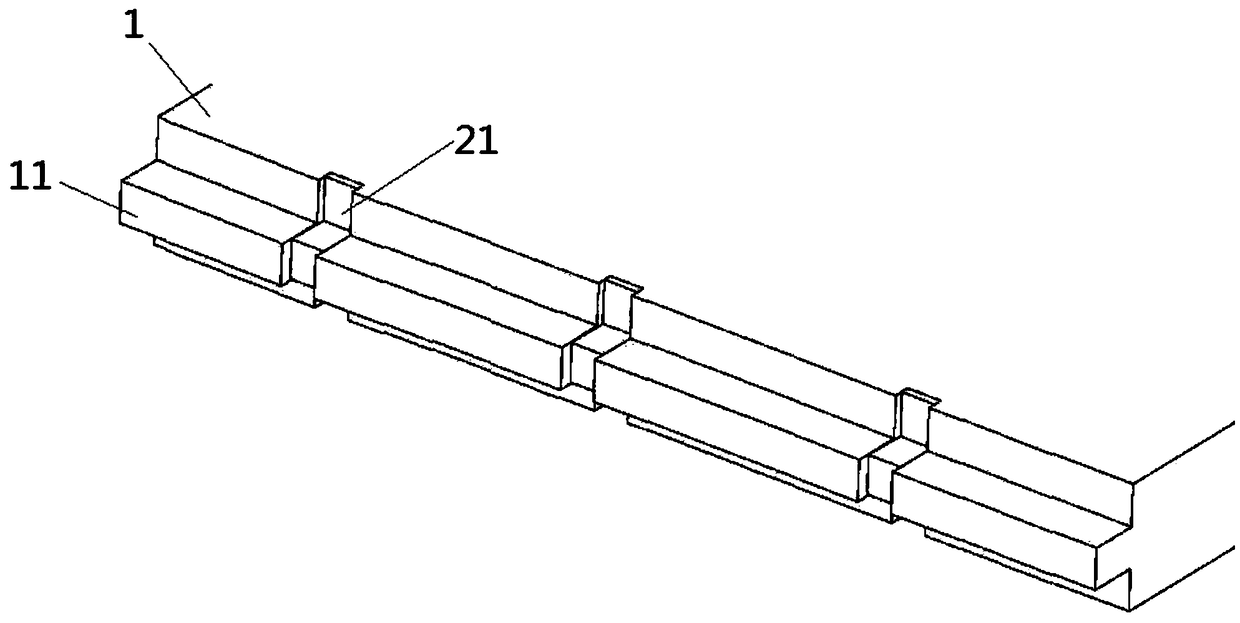

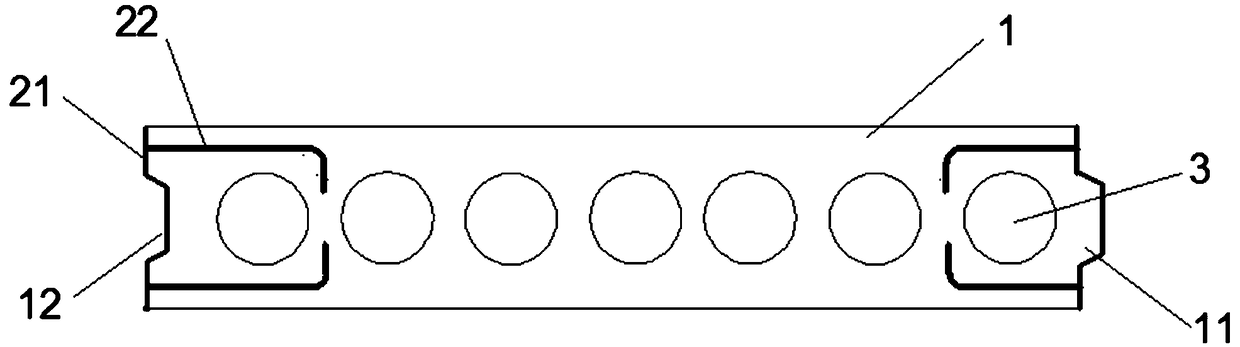

[0039] Such as Figure 1-Figure 5 As shown, a prefabricated assembled wall panel includes a panel body 1 and a plurality of connectors 2. One end surface of the panel body 1 is provided with a strip-shaped protrusion 11 extending from the top to the bottom in the length direction. There are strip-shaped grooves 12 matching the strip-shaped bumps 11 on the surface; the connecting piece 2 includes a butt plate 21 and a steel bar 22 connected thereto, and the end surface and its opposite surface are respectively provided with There are said butt-joint plates 21 that conform to the contour, and there are a plurality of butt-joint plates 21 evenly distributed in the length direction of the board body 1 , and the said steel bars 22 are pre-embedded in said board body 1 .

Embodiment 2

[0041] This embodiment is on the basis of embodiment 1:

[0042] Such as figure 2 and Figure 6 As shown, the butt plate 21 is embedded in the plate body 1, the upper surface of the butt plate 21 is recessed by 2 mm relative to the end surface of the plate body 1, and both sides of the butt plate 21 are exposed to the side surfaces of the plate body 1. , a 4mm weld seam 24 can be formed during butt jointing, welding rods can be put in, and it is convenient for the operator to weld from the side of the wallboard. It should be noted that the upper surface of the butt plate is relative to the lower surface of the butt plate that is in contact with (or opposite to) the end surface of the plate body. end face of the slot. The upper surface of the butt plate and the end surface of the plate body involved in the following embodiments can be understood as the same definition.

Embodiment 3

[0044] This embodiment is on the basis of embodiment 1:

[0045] Such as figure 2 and Figure 6 As shown, the butt plate 21 is embedded in the plate body 1, the upper surface of the butt plate 21 is recessed by 3 mm relative to the end face of the plate body 1, and both sides of the butt plate 21 are exposed to the sides of the plate body 1. , A 6mm weld seam 24 can be formed during butt jointing.

[0046] Such as Figure 3-Figure 5 As shown, the strip-shaped protrusion 11 is a trapezoidal column structure, and the end of the trapezoidal column close to the panel body 1 is larger than the end far away from the panel body, which facilitates relative splicing of two wall panels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com