Wall brick height support regulator

A technology of adjuster and height, which is applied in the direction of construction and building construction, can solve the problems of inconvenient rotation of nuts, low efficiency, inconvenient operation, etc., and achieve the effect of overcoming the inconvenience of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

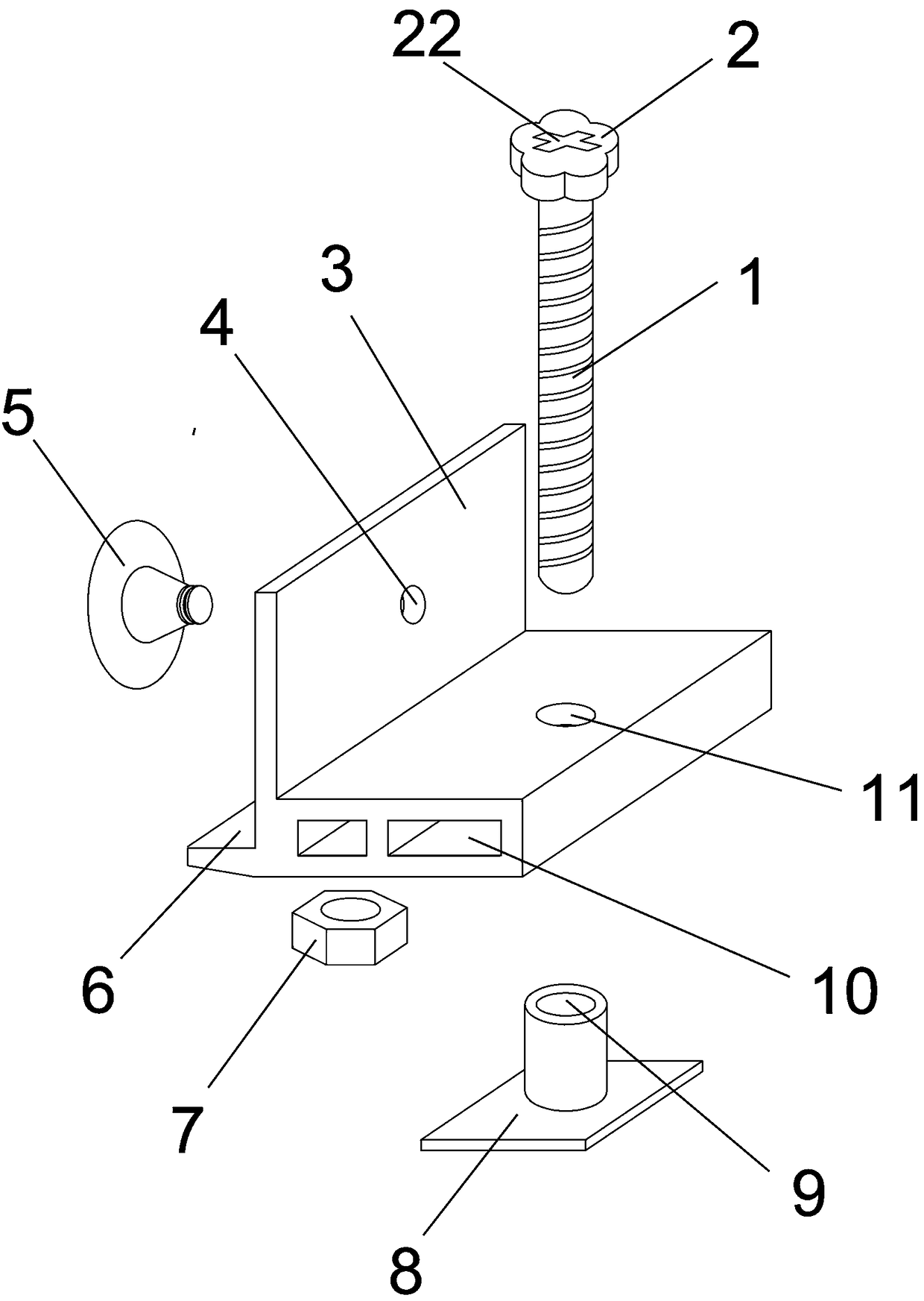

[0022] With reference to the accompanying drawings, the wall brick height support regulator includes a support member, the middle part of the support member is provided with a vertically upward backing plate 3, and the side of the support member against the wall is provided with a support plate 6 perpendicular to the backing plate. A through groove 10 is opened on the side, and a through hole 11 is provided vertically to allow the screw to pass through. The direction of the through groove is consistent with the length direction of the support. The nut is stuck in the through groove, and the center of the nut 7 coincides with the center of the through hole 11. The screw 1 with the handle 2 on the upper end is threadedly matched with the nut and penetrates the support, the distance between the center of rotation of the screw and the backing of the support is greater than 2 cm; a suction cup 4 is fixed on the backing of the side of the support against the wall; a base is provided ...

Embodiment 2

[0029] Different from the first embodiment, the present embodiment is provided with a cross slot 22 on the upper surface of the screw rod to match with the head of a Phillips screwdriver. The height of the support is adjusted by touching the screwdriver into the cross slot on the upper end surface of the screw rod for rotation, and the screwdriver rotation adjustment is also more convenient and efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com