Magnetic speed reducer for vehicle braking installed on driving shaft

A vehicle braking and decelerator technology, applied in the field of magnetic decelerators and magnetic decelerators for vehicle braking, can solve the problems of large consumption, high heating temperature of oil, easy deterioration, etc., to reduce pressure and avoid oil leakage. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

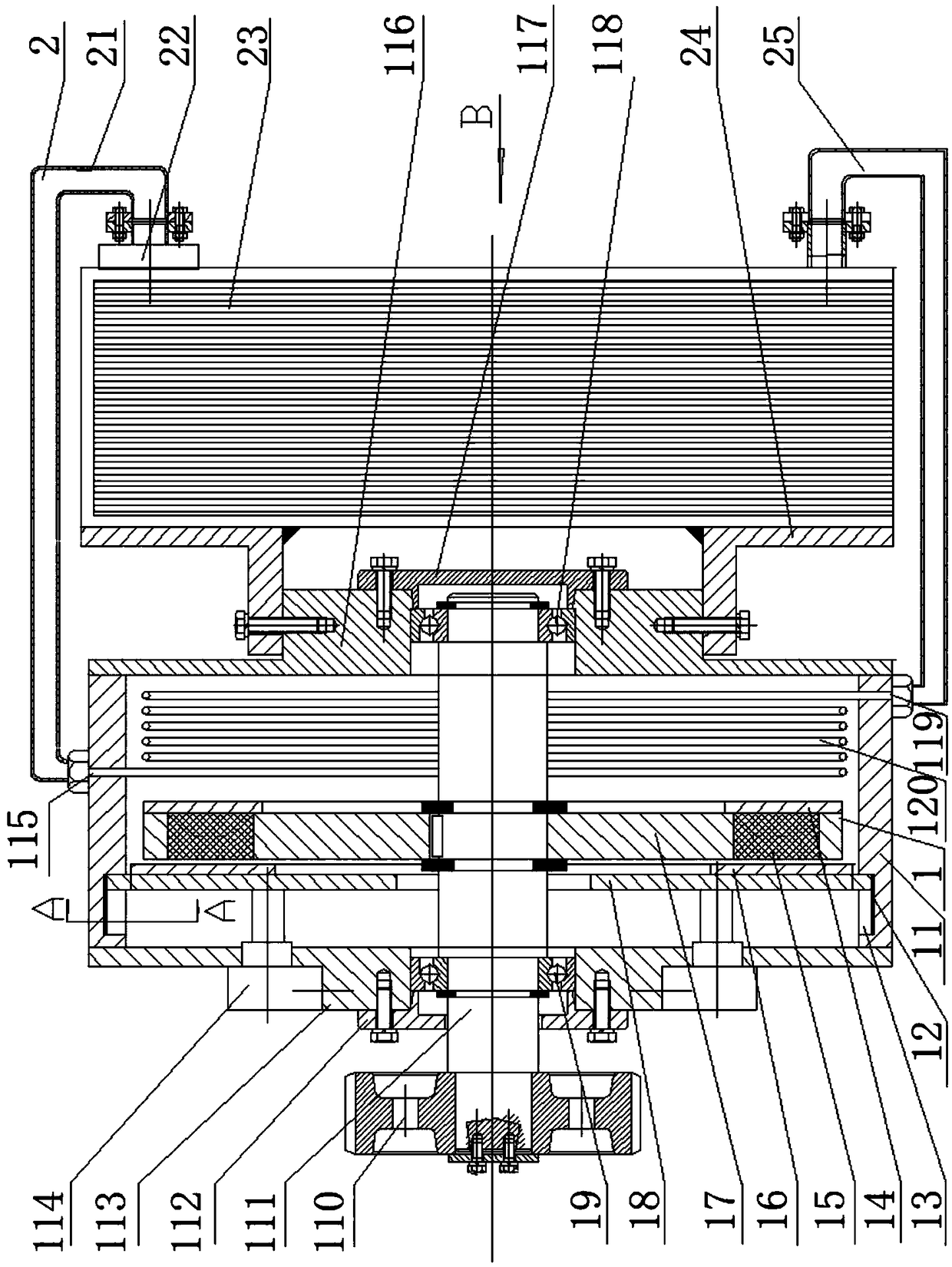

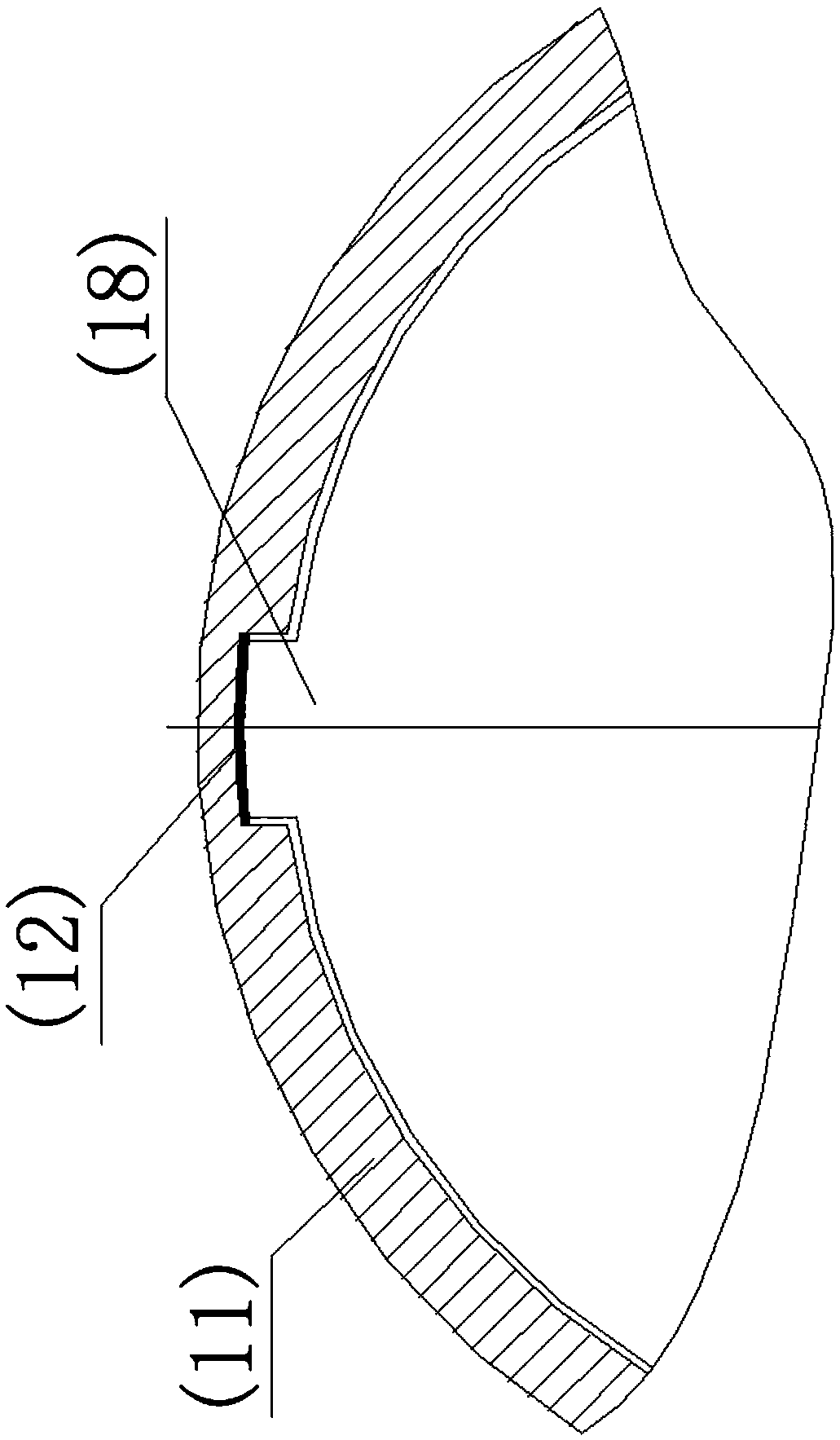

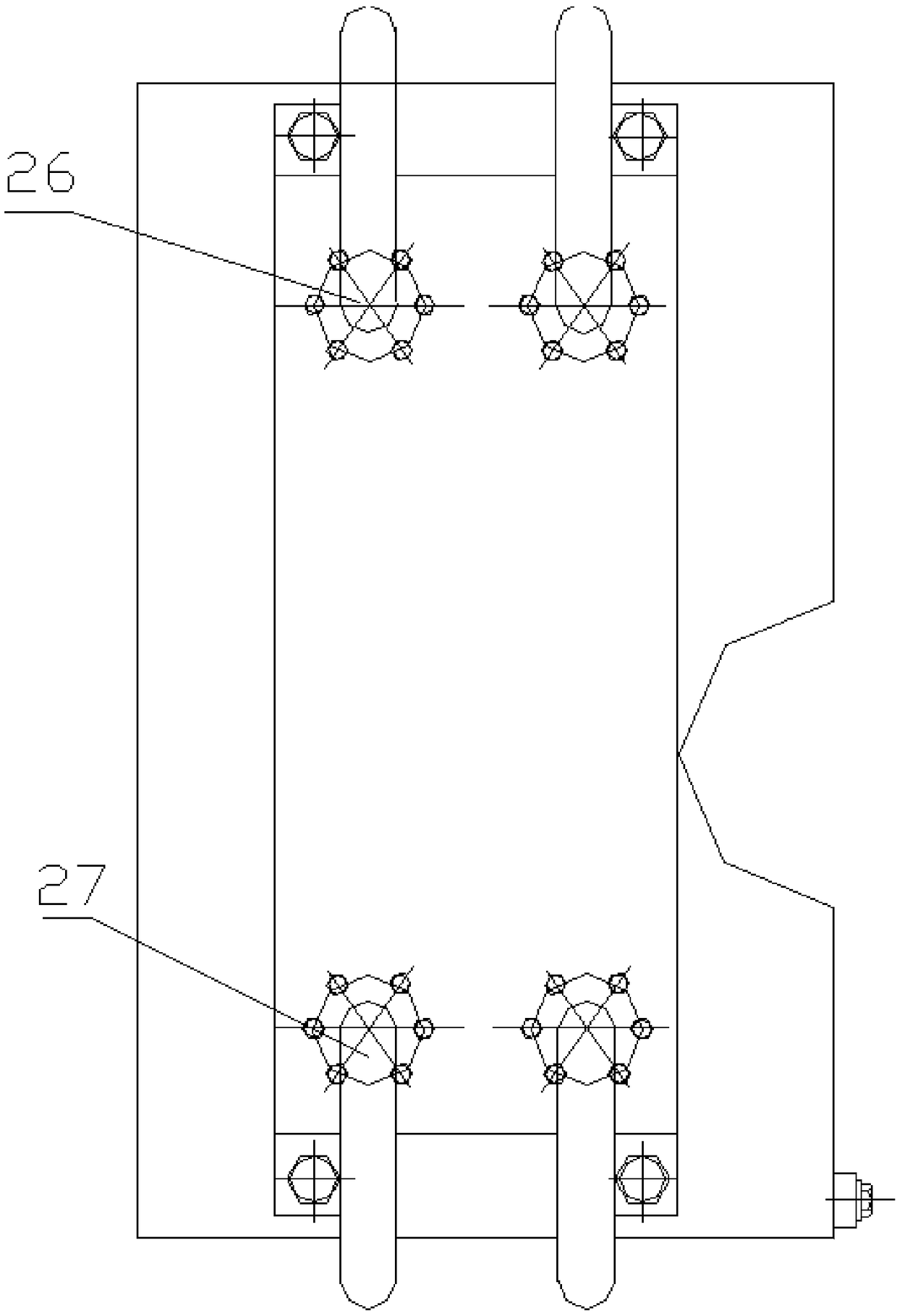

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 A magnetic speed reducer for vehicle braking shown on the drive shaft includes a magnetic speed reducer 1, a cooling system 2, a vehicle water tank 3, and a vehicle drive shaft gear 4. It is characterized in that the magnetic speed reducer 1 is composed of Connecting body 11, wear-resistant layer 12, chute 13, spacer disk 14, magnet 15, copper disk 16, disk body 17, copper disk body 18, bearing I19, speed-increasing gear 110, shaft 111, end cover I112, body frame Ⅰ113, reversing hydraulic cylinder 114, water inlet flange 115, body frame Ⅱ 116, end cover Ⅱ 117, bearing Ⅱ 118, return water flange 119, cooling water pipe 120, body frame Ⅰ 113, and body frame Ⅱ 116 pass through the connecting body 11 After forming an integrated frame, it is fastened on the bracket 24 installed on the car body. The speed-increasing gear 110 is installed on one end of the shaft 111. The shaft 111 is supported on the integrated frame by th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap