Mechanical seal testing device for aviation pump

A mechanical seal and test device technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of increased fuel consumption, achieve the effects of easy disassembly, accurate test results, and reduced test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

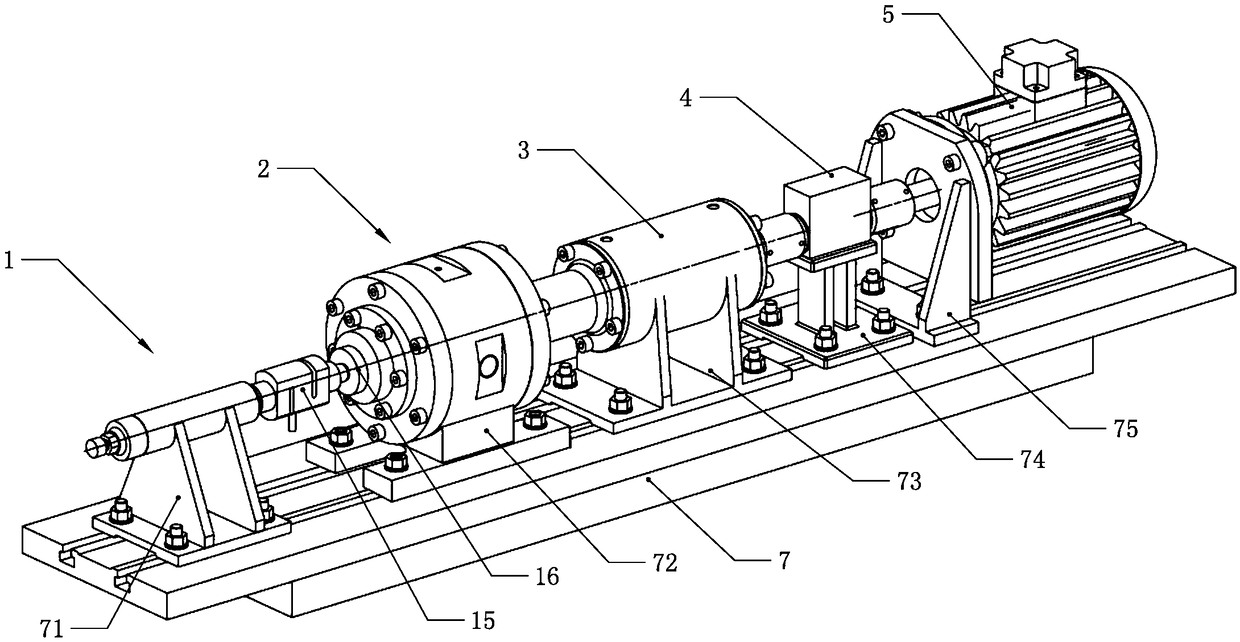

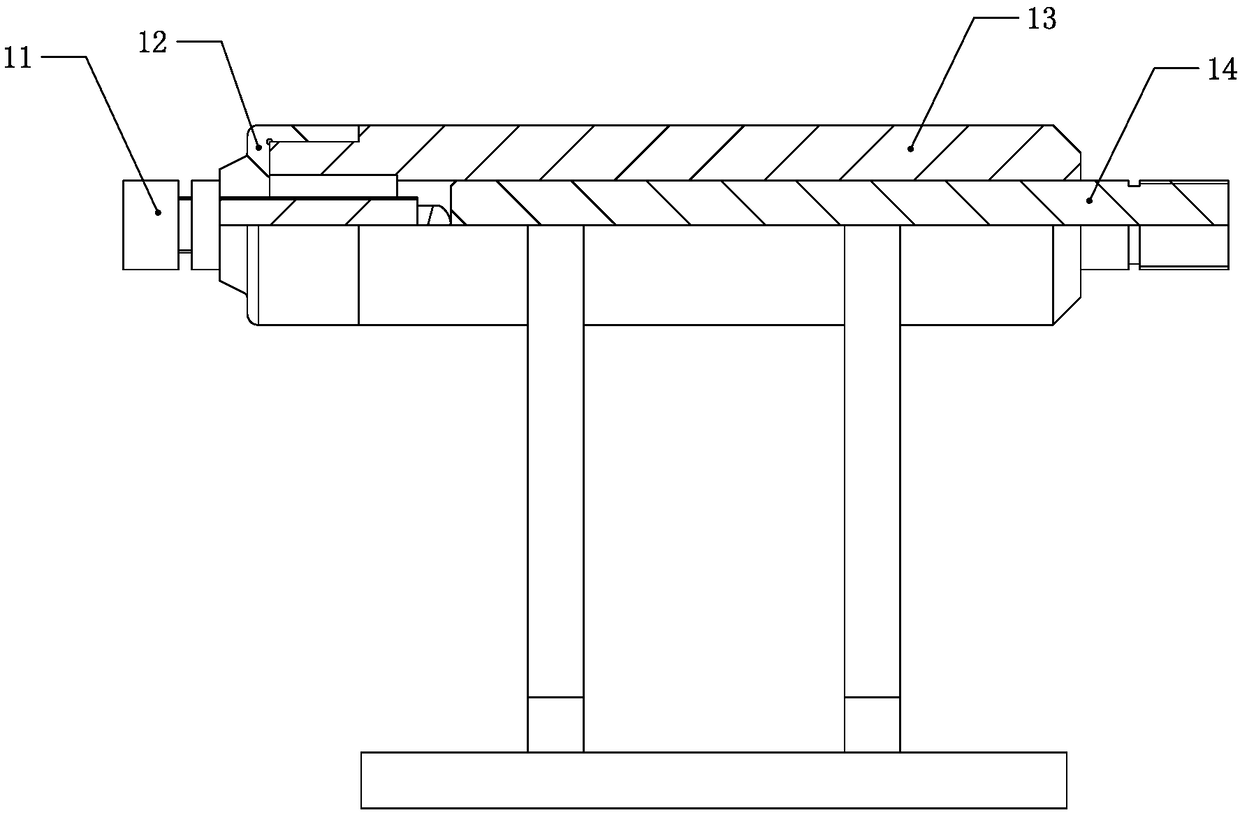

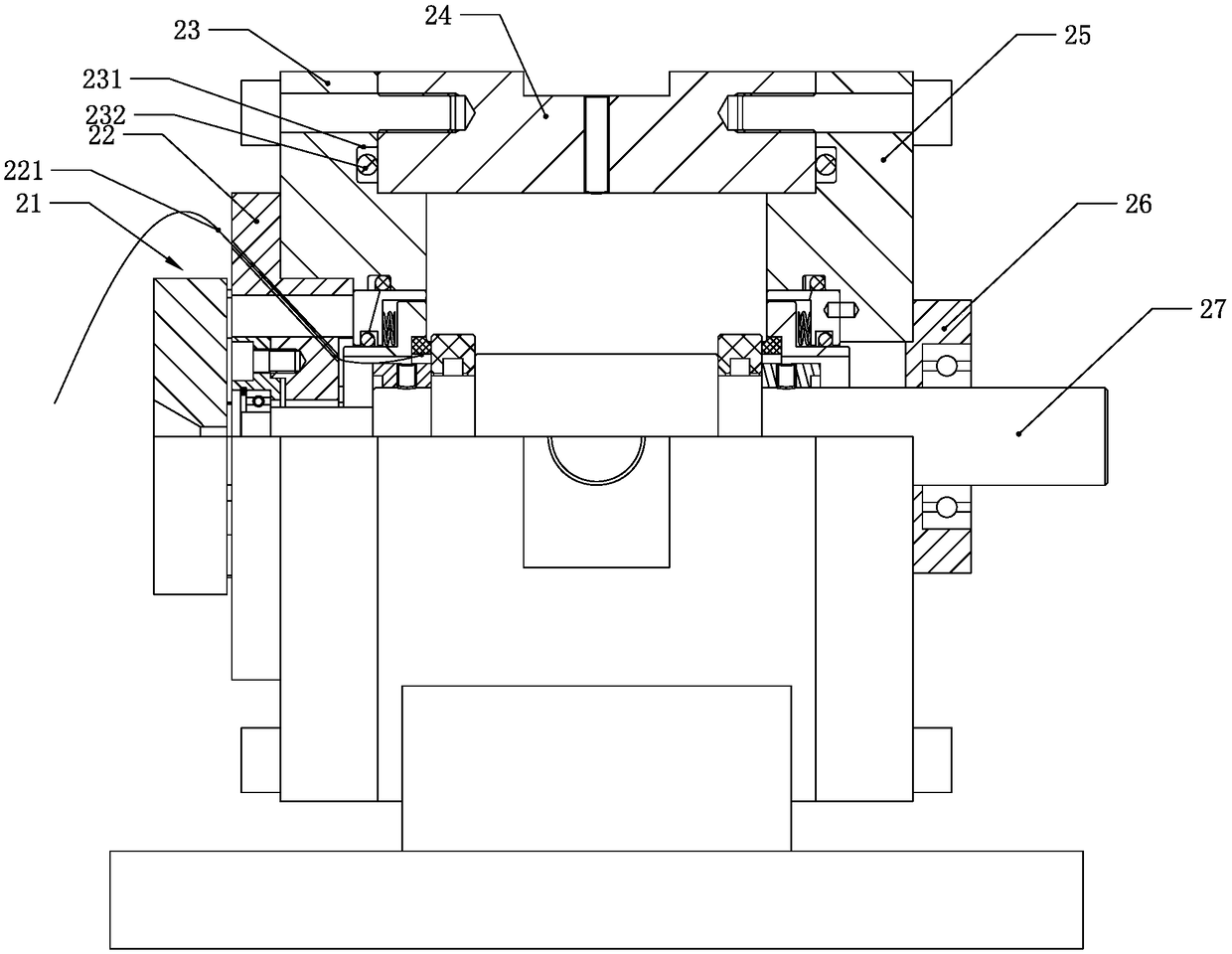

[0032] Such as Figure 1 to Figure 7 As shown, a kind of aviation pump mechanical seal test device provided by the present invention includes a test bench base 7, which is provided with a shaft tail loading force device 1, a test chamber 2, a lubricating device 3, and a torque sensor connected in sequence on the test bench base 7. 4 and the servo motor 5, the end of the main shaft 27 is connected with the servo motor 5, the other end of the main shaft 27 is sequentially passed through the torque sensor 4, the lubricating device 3 and the test chamber 2, and the end of the shaft loading device 1 is the end of the main shaft 27. The part provides loading force, the lubricating device 3 provides lubrication for the rotation of the main shaft 27, the torque sensor 4 detects the torque of the main shaft 27, and the servo motor 5 controls the rotating spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com