A rotary machine failure diagnosis method based on improved synchronous extrusion transformation

A technology of synchronous extrusion and rotating machinery, which is applied in the direction of machine/structural component testing, measuring devices, instruments, etc., and can solve the problems of lack of versatility, large amount of calculation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings.

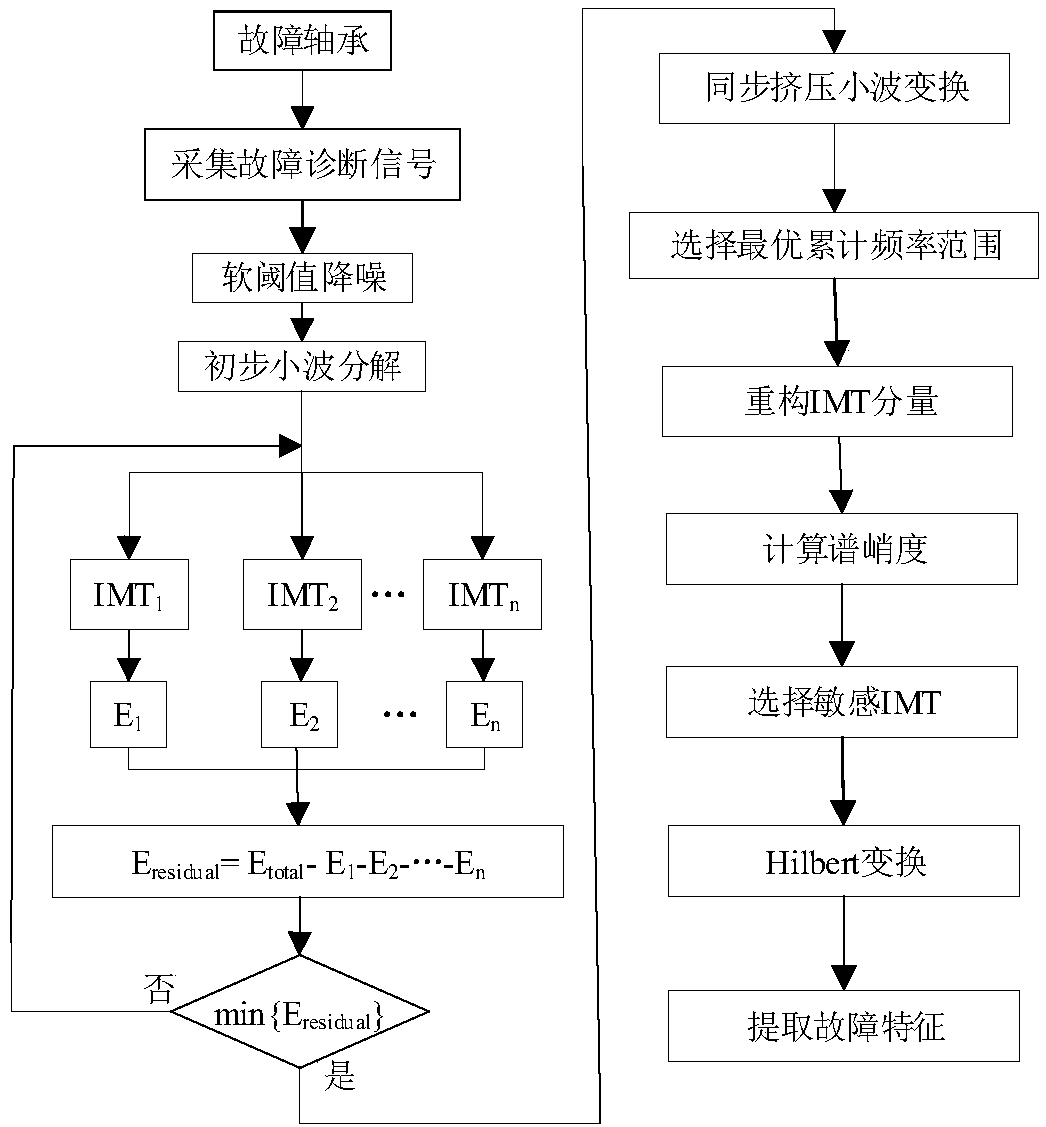

[0030] figure 1 Shown is the basic flow chart of the present invention. The method mainly includes the following three steps:

[0031] The first part: preprocessing the collected original vibration signal, the specific process is as follows:

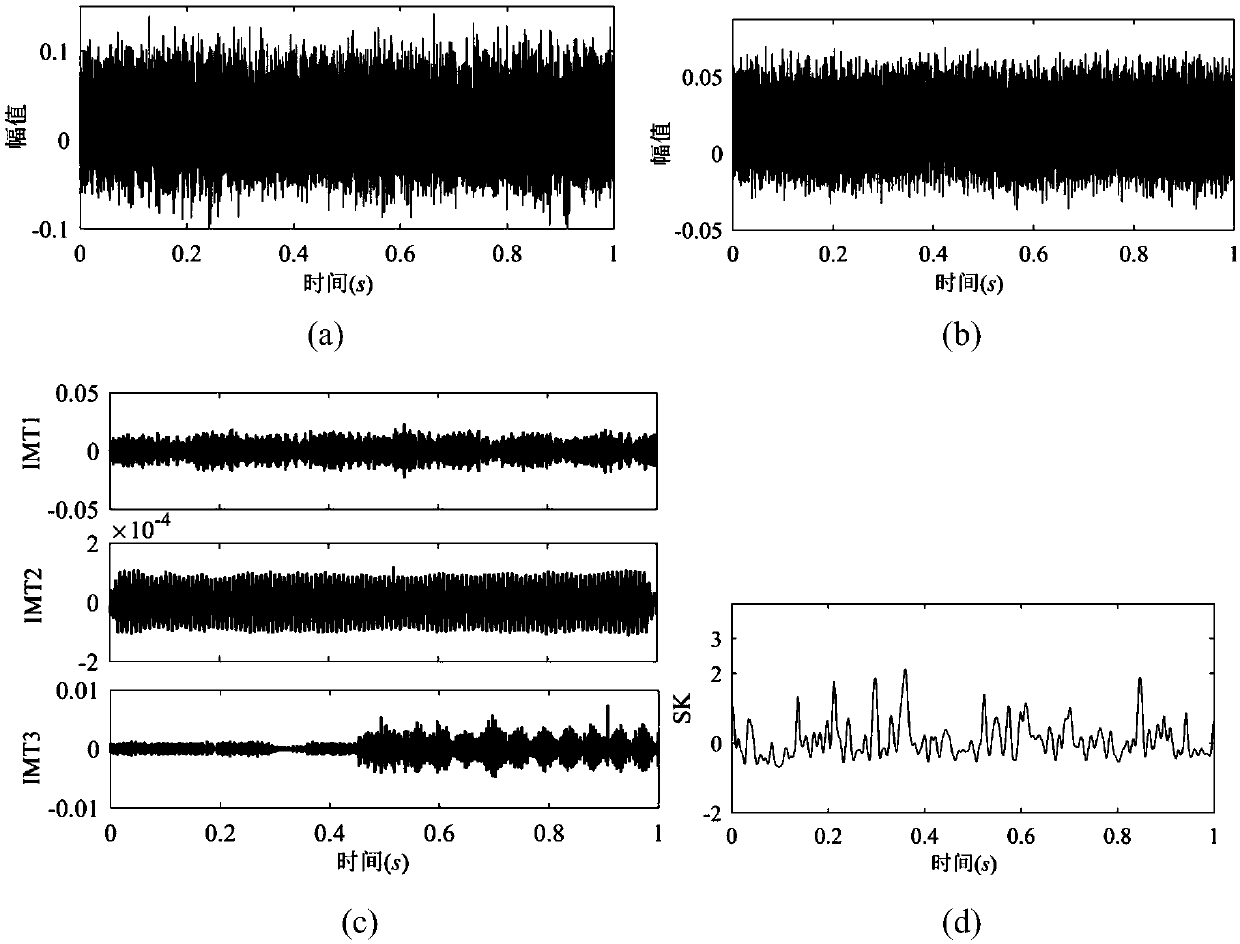

[0032] (1) Acquisition of vibration signals of rotating machinery with fault characteristics, such as figure 2 as shown in (a);

[0033] (2) According to Calculate the soft threshold, and design an adaptive filter, use the wavelet noise reduction method to filter out the noise components in the original signal, and extract the pure vibration signal, such as figure 2 as shown in (b);

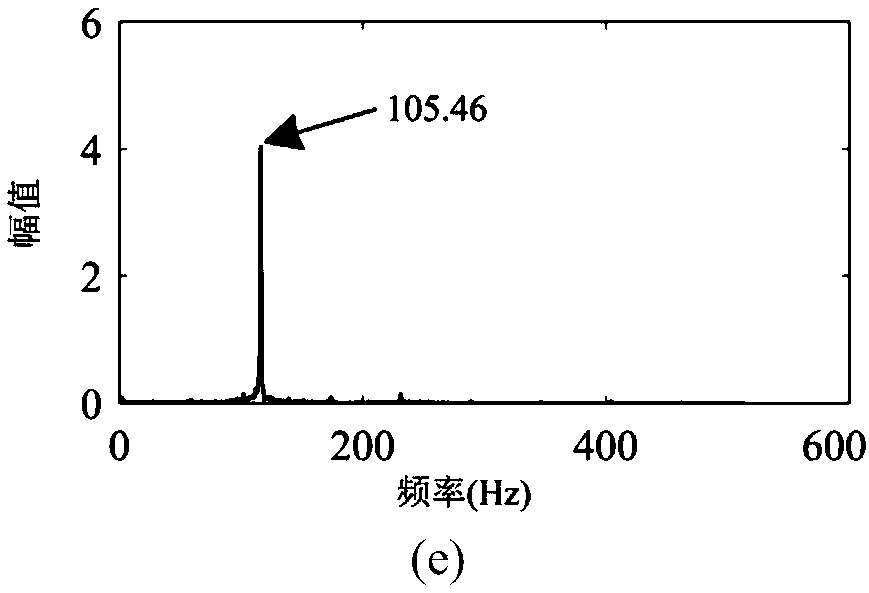

[0034] The second part: calculate the center frequency curve and the optimal frequency range, combined with the synchronous squeeze wavelet transform, decompose the vibration signal and reconstruct each component signal, the specific proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com