A method and system for on-site maintenance monitoring of special equipment

A technology for special equipment and maintenance, applied in general control systems, control/adjustment systems, program control, etc., can solve the problems of difficult maintenance quality assurance, poor monitoring accuracy, lack of effective monitoring methods for special equipment on-site maintenance, etc. problem, to achieve the effect of improving accuracy, improving accuracy and efficiency, and reducing the amount of monitoring data to be analyzed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

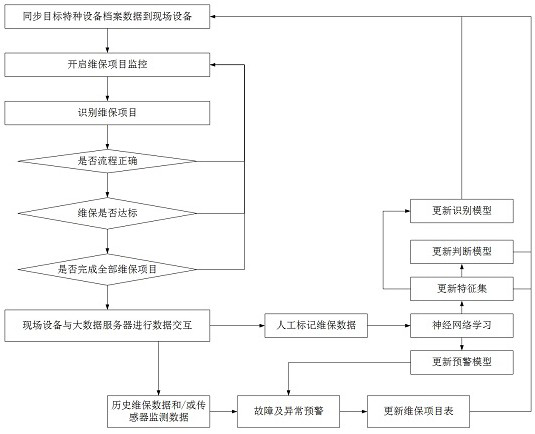

[0061] Embodiment one, take the project maintenance of elevator car door opening / closing as an example, the project maintenance of elevator car door opening / closing is carried out according to the following method: E1, on the big data server 100 at least store the information of the target special equipment The following data, as the file data of the target special equipment: a) elevator model, b) elevator car door model, c) image feature data of the car door, d) image feature data of devices related to car door opening / closing, e ) the speed curve of the normal switch of the car door, f) the normal movement speed curve of the device related to the opening / closing of the car door (in the form of a function or the parameter of the function), g) the data of the acceleration sensor installed on the car door, h) The failure prediction result of the big data server 100 (judgment based on the data that has been sent back from the site), i) the last maintenance time, maintenance resul...

Embodiment 2

[0062]Embodiment 2, for the project maintenance of the hoisting machinery traction wheel, adopt on-site maintenance monitoring to carry out as follows: F1, store the following data of the target special equipment on the big data server 100, as the file data of the target special equipment: a) The model of the hoisting machine, b) the model of the traction sheave, c) the image feature data of the traction sheave, d) the image feature data of the components related to the operation of the traction sheave, e) the speed curve of the normal operation of the traction sheave , f) the normal motion speed curve of the device related to the operation of the traction wheel, f) the failure prediction result of the big data server 100, g) the last maintenance time, maintenance result and device replacement record; wherein the image feature data includes: Pulley color, pulley texture, number of corners of polygonal pulley outline, corner smoothness of polygonal pulley outline, all or part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com