High-density winding punching sheet

A high-density, winding technology, applied in the direction of electric components, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of blown windings, motor operation effects, motor explosions, etc., to prevent damage and ensure normal use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

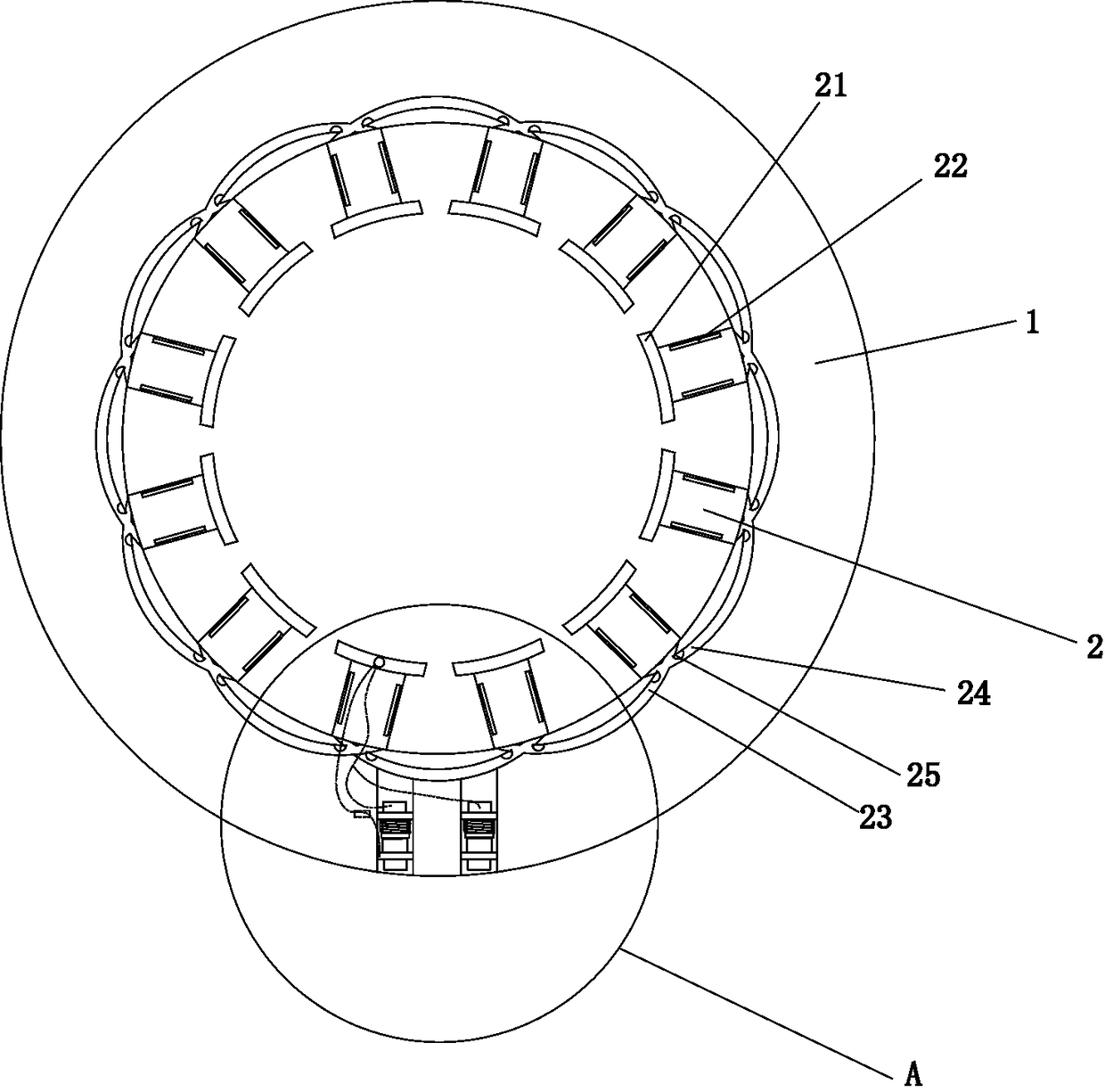

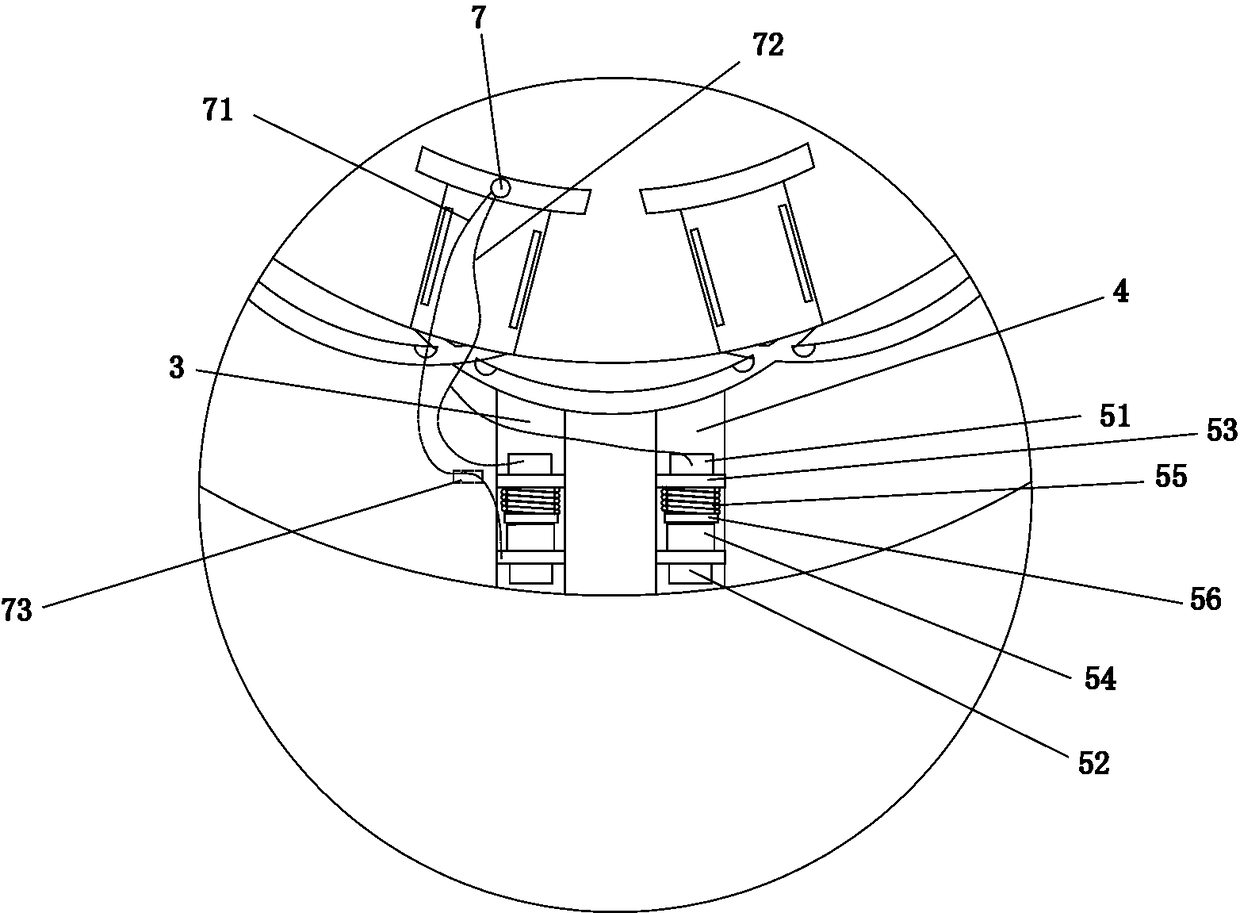

[0016] Embodiment 1: as Figure 1 to Figure 2 As shown, a high-density winding punch includes a yoke 1, the yoke 1 includes an inner circle, and a number of teeth 2 are arranged on a uniform circumference of the inner circle, and adjacent to the teeth 2 There is a circular arc transition between them. The top of the tooth portion 2 is provided with a blocking block 21 , and the tooth portion 2 is provided with cooling holes 22 . The surfaces of the yoke portion 1 and the tooth portion 2 are coated with insulating varnish. The yoke 1 is provided with winding entry slots 23 and winding exit slots 24 corresponding to the teeth 2 , and the winding entry slots 23 and winding exit slots 24 are respectively provided with anti-off pieces 25 . The yoke 1 is also provided with a winding wire inlet hole 3 and a winding wire outlet hole 4, and the winding wire inlet hole 3 and the winding wire outlet hole 4 are both provided with elastic connectors 51 and magnetic connectors 52 for conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com