Continuous complexation of active pharmaceutical ingredients

A technology for active pharmaceutical ingredients and drugs, applied in the field of complexes of active pharmaceutical ingredients, can solve the problems of increasing the ratio of active pharmaceutical ingredients/cyclodextrin and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

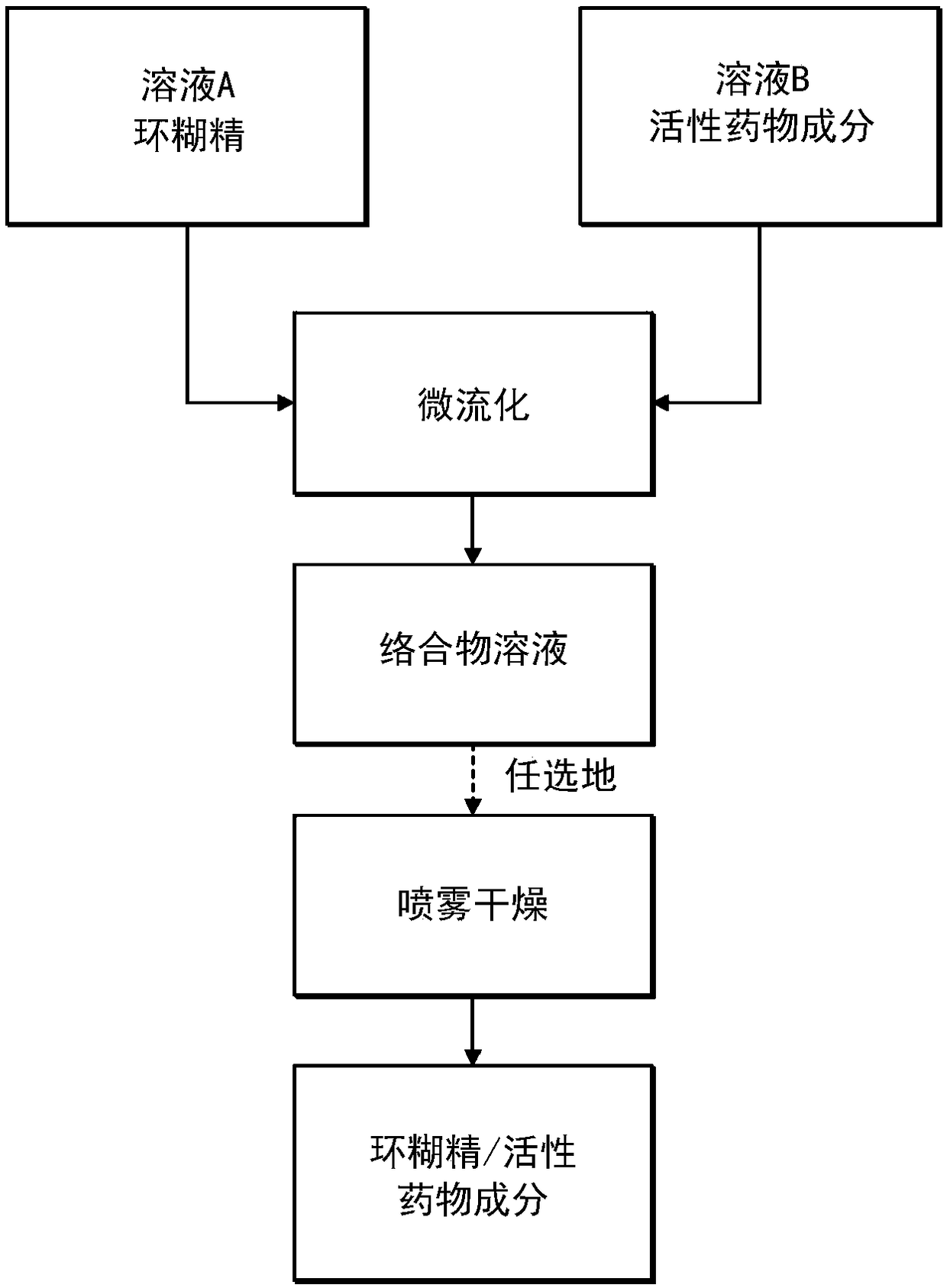

Method used

Image

Examples

Embodiment 1

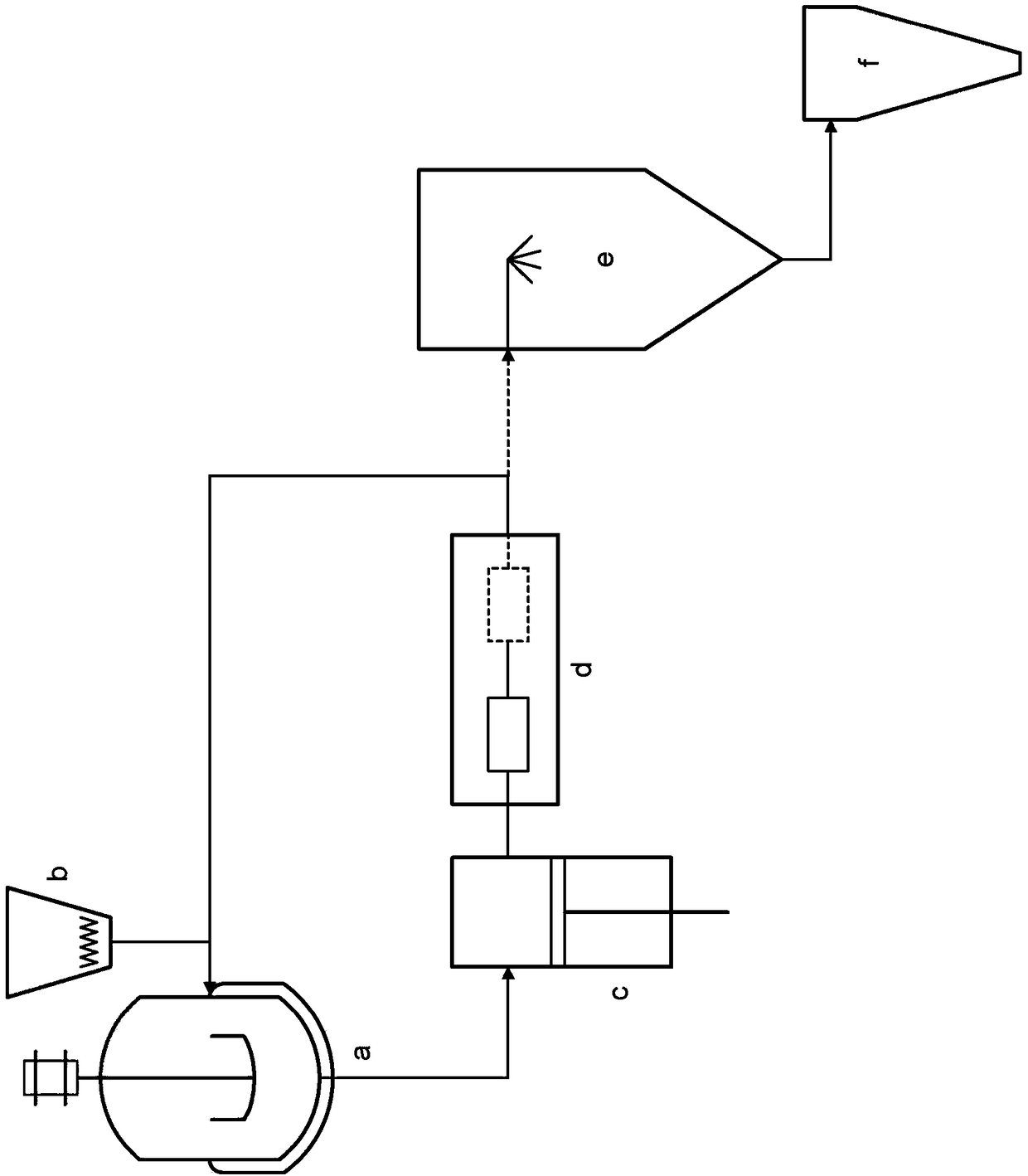

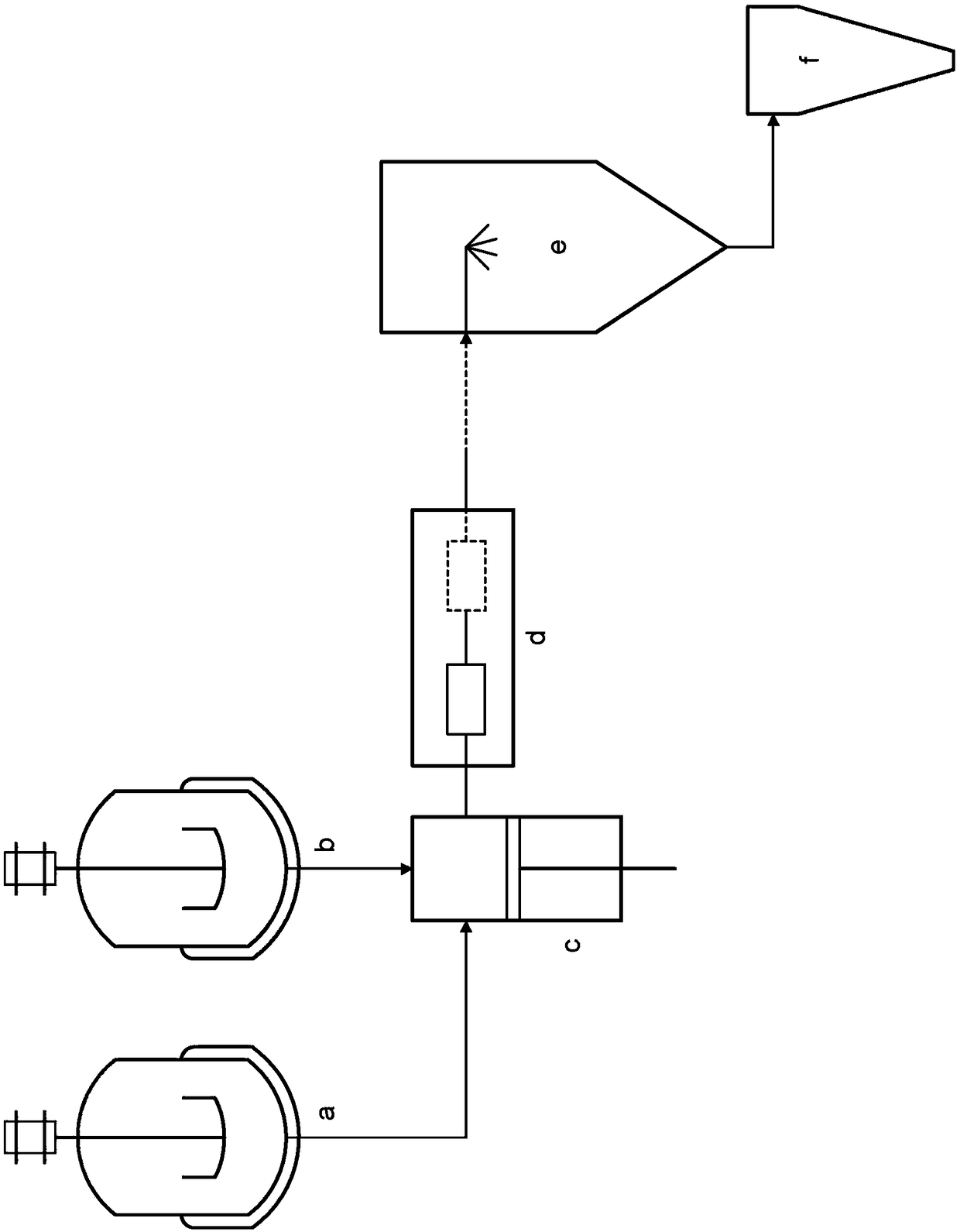

[0089] 60 grams of water were added to the stirred reactor. To this reactor was added 40 grams of sulfobutyl ether-β-cyclodextrin. The suspension was continuously stirred until a clear solution formed. Then, 1 gram of the active pharmaceutical ingredient (in this case using itraconazole as the model drug) was added to the solution and the timer was set immediately. The resulting suspension was stirred continuously at 25°C. 2 g of the suspension was filtered per day and analyzed by HPLC to determine the complex concentration. Figure 4 The results are shown in (dotted line).

Embodiment 2

[0091] 60 grams of water were added to the stirred reactor. To this reactor was added 40 grams of sulfobutyl ether-β-cyclodextrin. The suspension was continuously stirred until a clear solution formed. In the case of device A, 10 grams of the active pharmaceutical ingredient (itraconazole) was added to the solution and the timer was set immediately. The resulting suspension was fed to a booster pump at a pressure of 550 bar at room temperature for 1 hour. 2 g samples from the suspension were filtered every 10 minutes and analyzed by HPLC to determine the complex concentration. After 1 hour, the solution was spray-dried to obtain a powdery substance. Figure 4 The results are shown in (dotted line).

Embodiment 3

[0093] 60 grams of water were added to the stirred reactor. To this reactor was added 400 grams of sulfobutyl ether-beta-cyclodextrin. The suspension was continuously stirred until a clear solution formed. In the case of device A, 10 grams of the active pharmaceutical ingredient (itraconazole) was added to the solution and the timer was set immediately. The suspension formed was fed to a booster pump at a pressure of 550 bar at room temperature for 3 hours. 2 g samples from the suspension were filtered every 10 minutes and analyzed by HPLC to determine the complex concentration. After 3 hours, the solution was spray-dried to obtain a powdery substance. Figure 4 The results are shown in (solid line).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com