Method for rolling and/or heat treating metal products

A technology for products, metals, applied in the field of rolled and/or heat-treated metal products to optimize the manufacturing process, avoid follow-up costs, and reduce scrap costs

Active Publication Date: 2021-11-12

SMS GRP GMBH

View PDF23 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] So far, however, there is no way to ensure a stable control or regulation of a predetermined quality of a metal product after heat treatment or rolling in a sufficiently simple manner

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

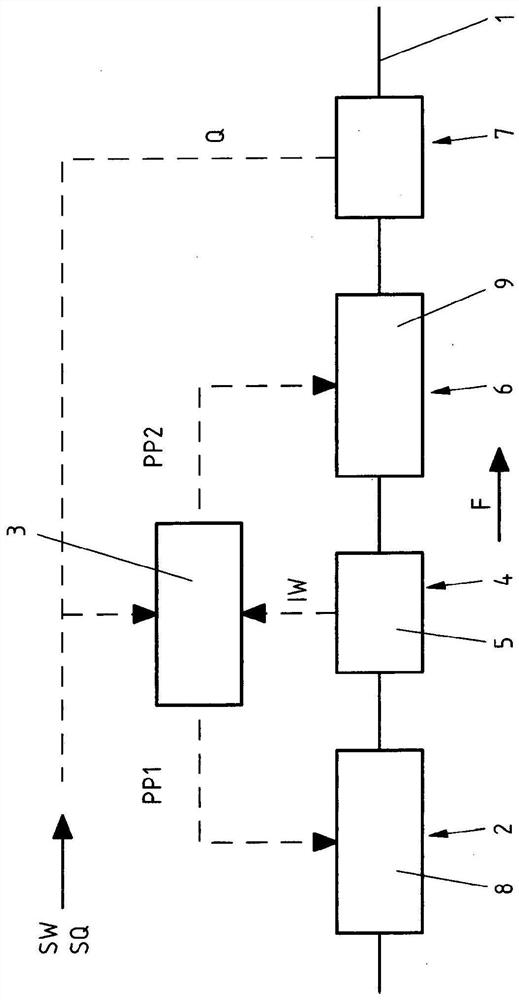

[0057] In the drawings, an example of a process for manufacturing a metal strip 1 (steel strip) is schematically shown. The example shown is a continuous heat treatment process of the strip, in which the strip 1 is heated in the desired temperature range.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for rolling and / or heat treating a metal product (1), wherein the product is subjected at a first position (2) to a rolling operation regulated by a regulating device (3) , wherein the product ( 1 ) is measured at the second position ( 4 ), the product ( 1 ) is subjected to further processing operations at the third position ( 6 ), and at the fourth position ( 7 ) a predetermined quality Product (1). In order to improve the quality of the produced strip, the invention provides that the method has the following steps: a) measuring the value of the material property (IW) at the second position (4); b) measuring the value of the material property (IW) at the second position (4); The measured value is transmitted to the regulating device (3), the measured value is compared with the value (SW) stored in the regulating device (3), and if the measured value deviates from the stored value (SW), Adjusting the parameter (PP1); c) measuring the value of the quality material property (Q) at the fourth position (7); d) comparing the measured value with the stored value, and if the measured value is the same as the stored value If the difference exceeds the permissible tolerance, measures for influencing the quality parameter performance (Q) are initiated.

Description

technical field [0001] The invention relates to a method for rolling and / or heat-treating a metal product, in particular strip, wherein said product is subjected to a rolling and / or heat-treating operation at a first location, said rolling and / or The heat treatment operation is controlled and / or regulated by control and / or regulating means, wherein the product is measured by means of measuring means at a second position after the first position, the product is at a third position after the second position It is subjected to another processing operation and a product of preset quality is obtained at a fourth location after the third location. Background technique [0002] The predetermined quality can be, but need not necessarily be, the final quality of the product, wherein the product is in particular a strip or a plate. The sequence of positions is to be understood in particular along the conveying direction or in the sense of a production sequence. In connection with th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D8/02B21B37/74B21B37/76C21D8/04C21D9/46C21D11/00

CPCB21B37/74B21B37/76C21D8/02C21D8/0226C21D8/0426C21D9/46C21D11/005C21D8/0205C21D8/0263C21D8/0278C21D9/562C21D9/573G05B13/02G05B19/41875B21B1/22B21B2001/225C23C2/40G01N23/2055

Inventor M·比格拉里H·贝伦斯C·A·克莱恩C·克林肯贝格L·屈梅尔U·左默斯

Owner SMS GRP GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com