Sulfur smashing device for chemical materials

A crushing device and a technology for chemical raw materials, which are applied in transmission devices, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of using a lot of manpower, consuming a lot of time, and poor use effects, so as to achieve convenient use and saving The effect of time and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

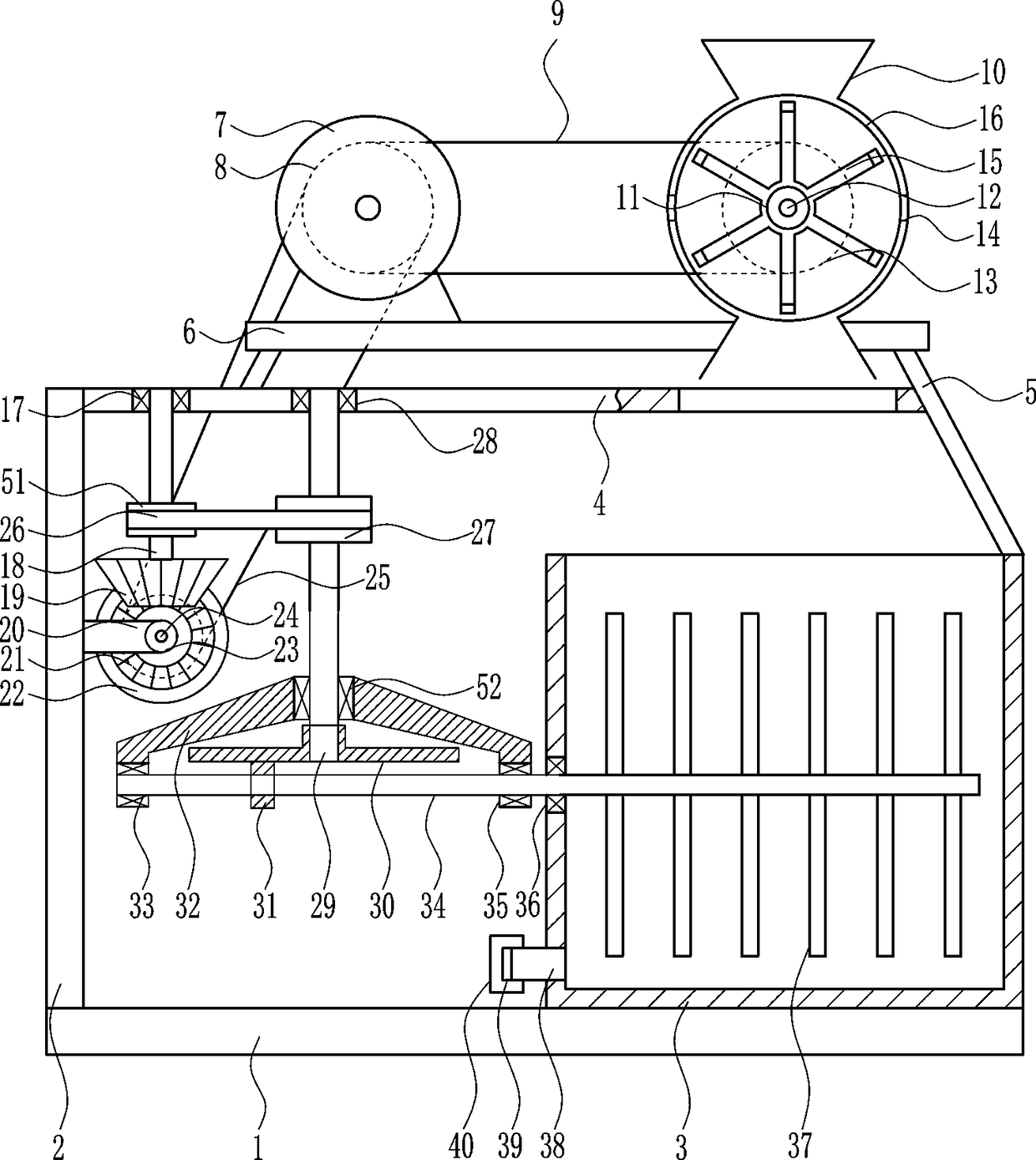

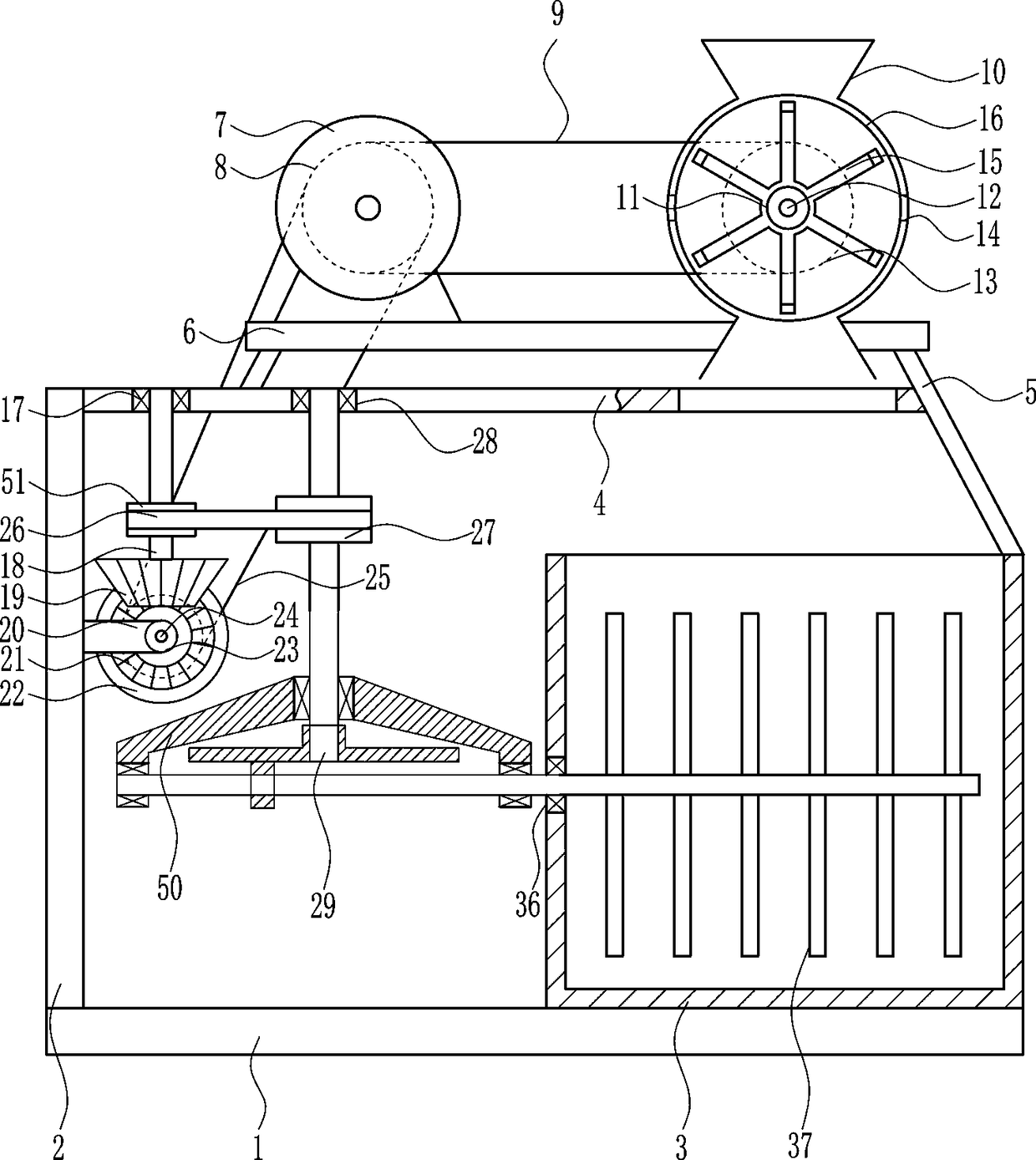

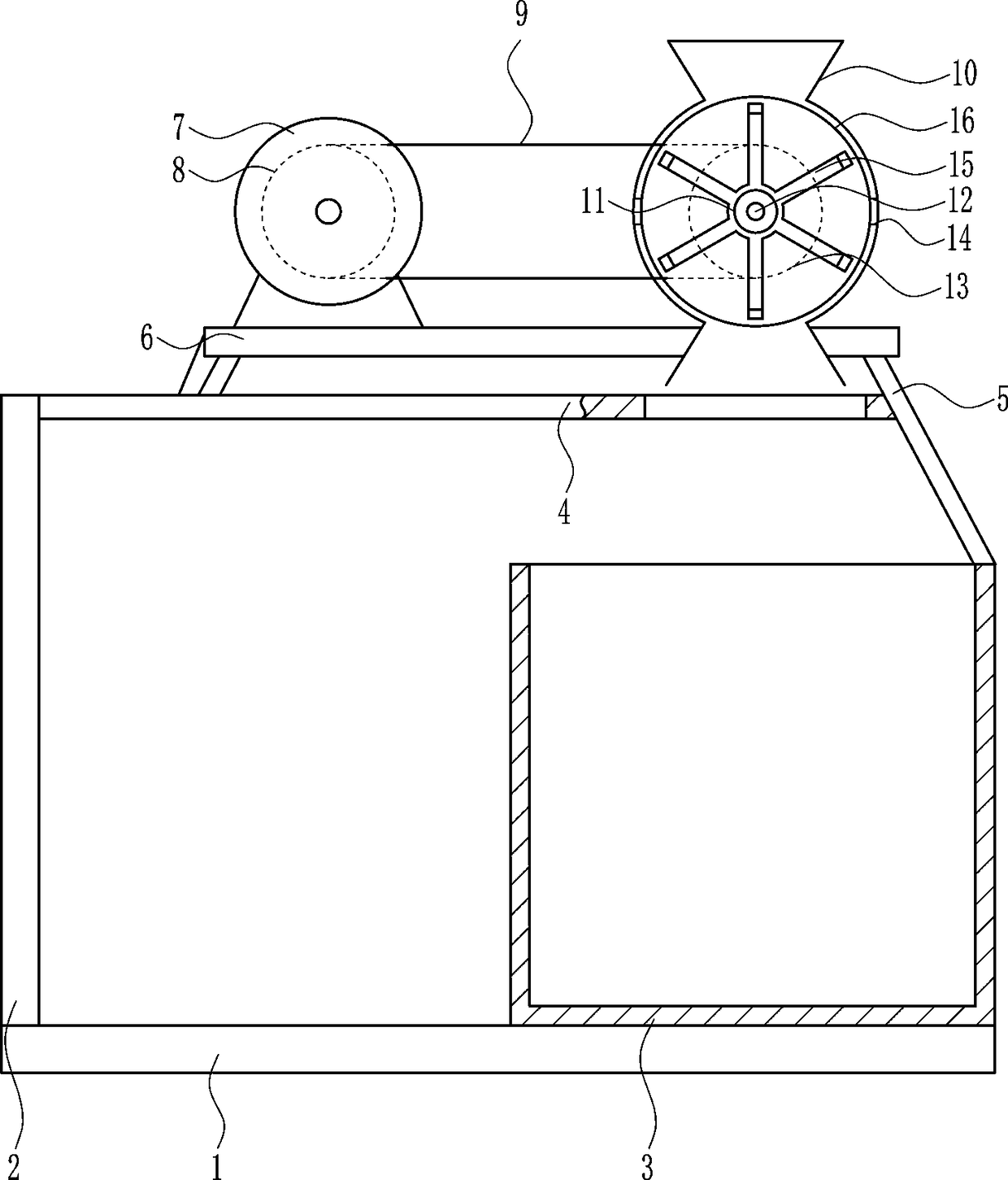

[0024] A sulfur crushing device for chemical raw materials, such as Figure 1-5 As shown, it includes a base 1, a first support rod 2, a material storage box 3, a first support plate 4, a second support rod 5, a second support plate 6, a motor 7, a first pulley 8, and a first connecting belt 9 , housing 10, first bearing 11, first rotating shaft 12, second pulley 13, connecting block 14, crushing wheel 15 and filter screen 16, base 1 upper left part is equipped with first support bar 2, and first support bar 2 top is installed There is a first support plate 4, a material storage box 3 is installed on the upper right part of the base 1, a second support bar 5 is installed on the top of the material storage box 3, a second support plate 6 is installed on the top of the second support bar 5, and a second support plate 6 is installed on the top of the second support bar 5. A motor 7 is installed on the left upper part, a first pulley 8 is installed on the motor 7, a housing 10 is ...

Embodiment 2

[0026] A sulfur crushing device for chemical raw materials, such as Figure 1-5As shown, it includes a base 1, a first support rod 2, a material storage box 3, a first support plate 4, a second support rod 5, a second support plate 6, a motor 7, a first pulley 8, and a first connecting belt 9 , housing 10, first bearing 11, first rotating shaft 12, second pulley 13, connecting block 14, crushing wheel 15 and filter screen 16, base 1 upper left part is equipped with first support bar 2, and first support bar 2 top is installed There is a first support plate 4, a material storage box 3 is installed on the upper right part of the base 1, a second support bar 5 is installed on the top of the material storage box 3, a second support plate 6 is installed on the top of the second support bar 5, and a second support plate 6 is installed on the top of the second support bar 5. A motor 7 is installed on the left upper part, a first pulley 8 is installed on the motor 7, a housing 10 is i...

Embodiment 3

[0029] A sulfur crushing device for chemical raw materials, such as Figure 1-5 As shown, it includes a base 1, a first support rod 2, a material storage box 3, a first support plate 4, a second support rod 5, a second support plate 6, a motor 7, a first pulley 8, and a first connecting belt 9 , housing 10, first bearing 11, first rotating shaft 12, second pulley 13, connecting block 14, crushing wheel 15 and filter screen 16, base 1 upper left part is equipped with first support bar 2, and first support bar 2 top is installed There is a first support plate 4, a material storage box 3 is installed on the upper right part of the base 1, a second support bar 5 is installed on the top of the material storage box 3, a second support plate 6 is installed on the top of the second support bar 5, and a second support plate 6 is installed on the top of the second support bar 5. A motor 7 is installed on the left upper part, a first pulley 8 is installed on the motor 7, a housing 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com