Mold for producing aluminum soup pot with pot lugs and production method adopting mold

An aluminum soup pot and mold technology for pot ears, which is applied to household appliances, other household appliances, applications, etc., can solve problems such as affecting the molding effect, affecting the molding quality, and the elastic rubber block is prone to aging, so as to improve the quality and improve the orientation. , Improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

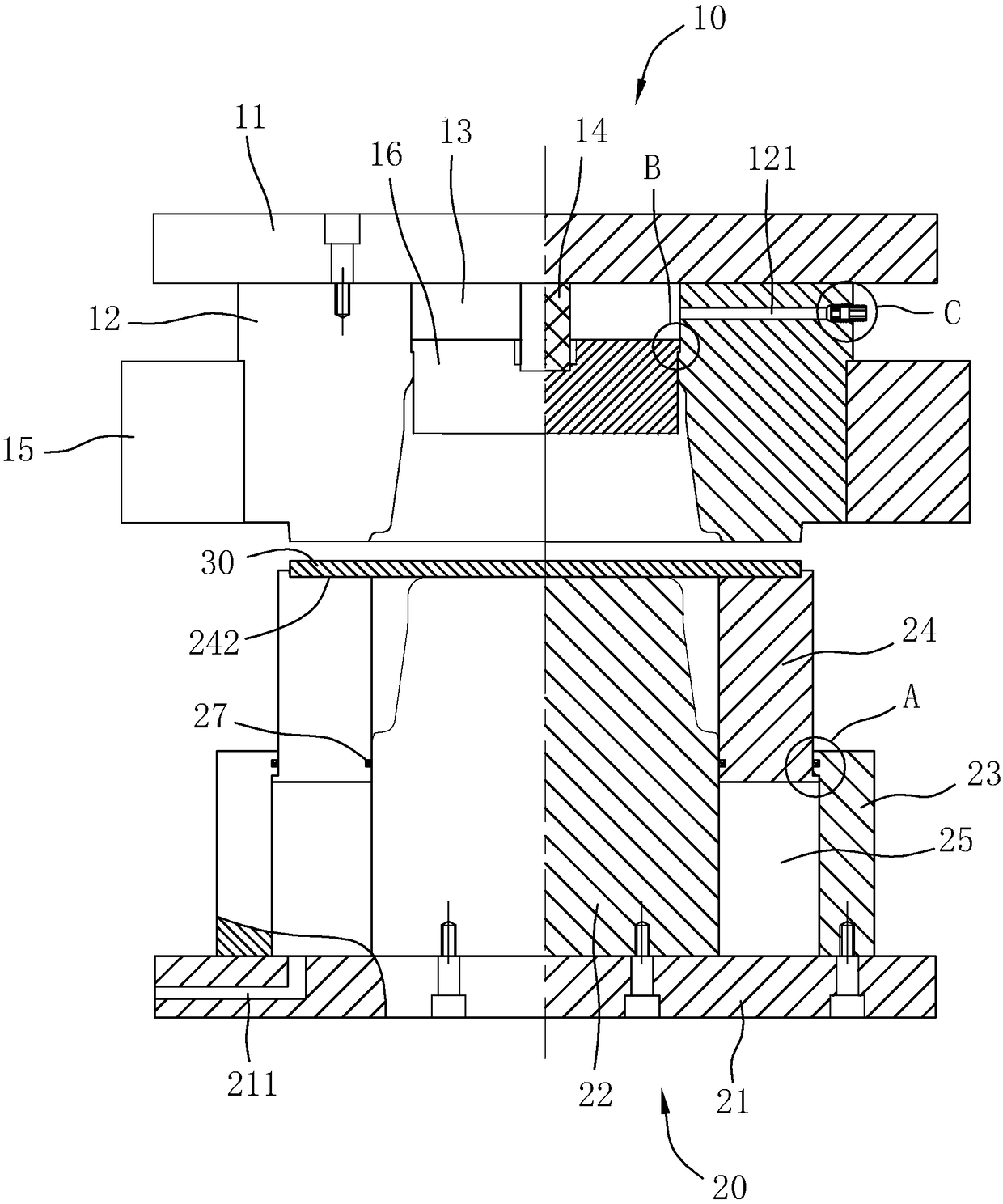

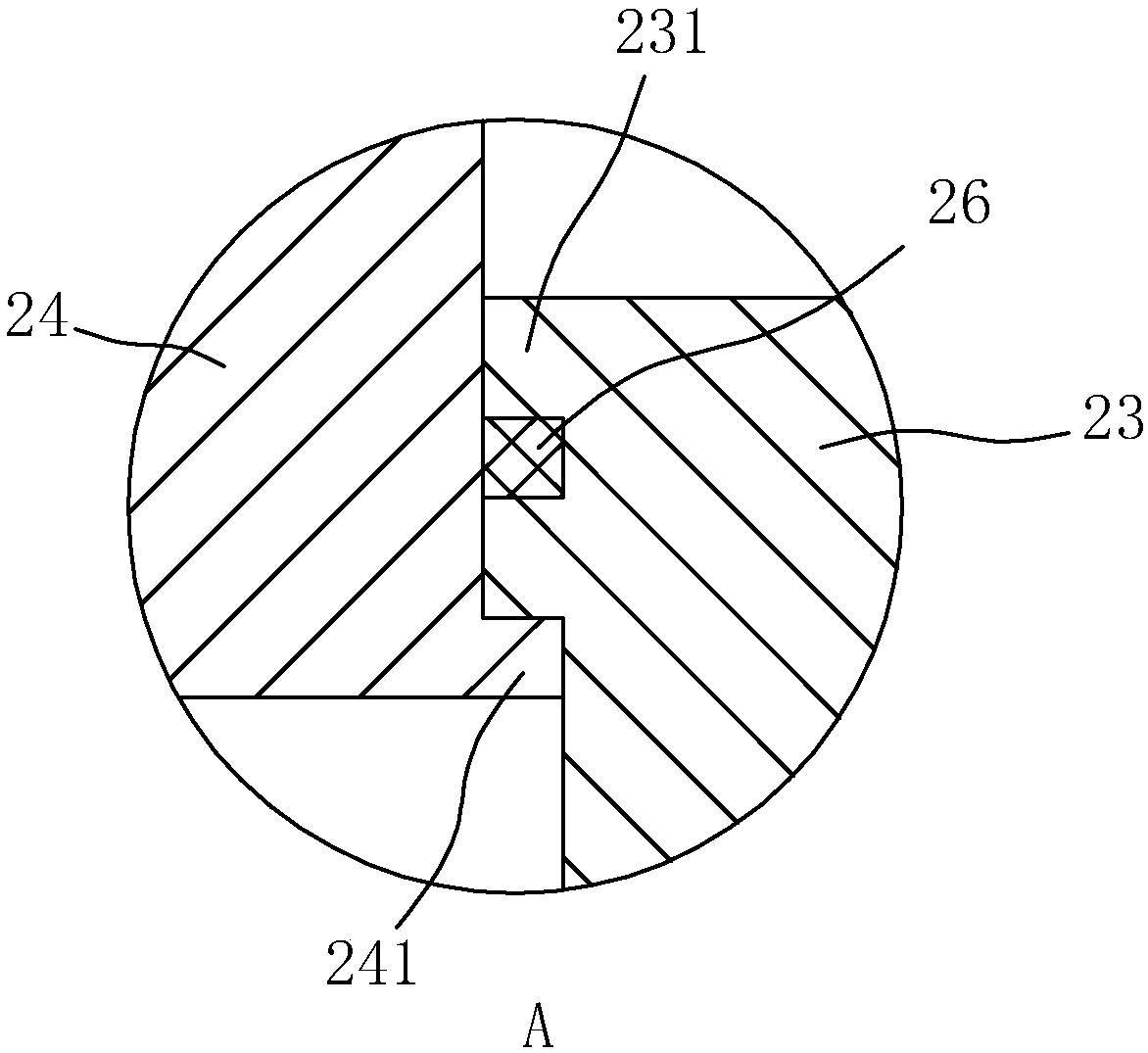

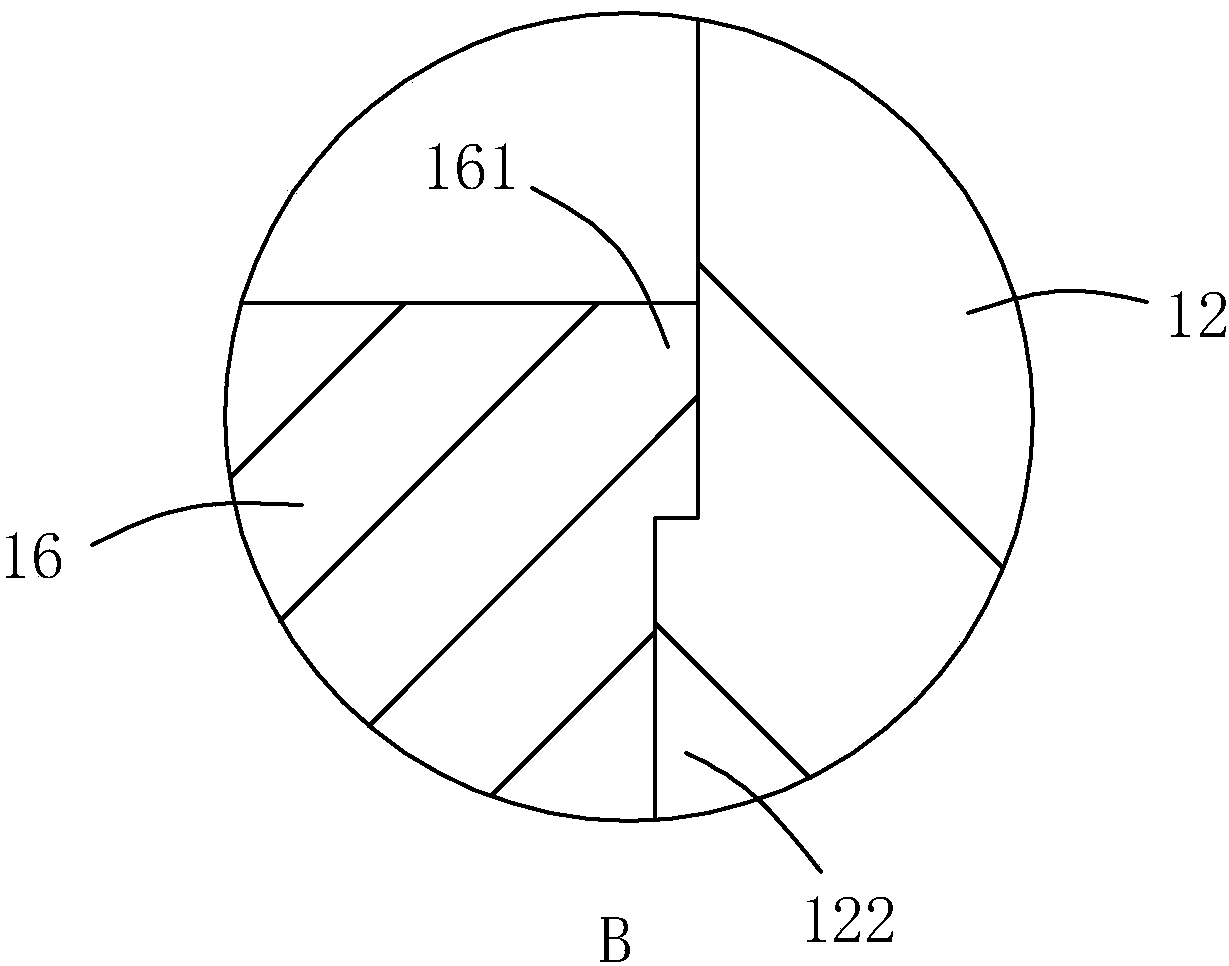

[0049] see figure 1 , a mold for producing an aluminum soup pot 50 with pot ears 52, including an upper mold 10 and a lower mold 20. The lower die 20 includes a lower die connecting plate 21 on which a punch 22 and a guide ring 23 sleeved on the outer ring of the punch 22 are fixed. The guide ring 23 coincides with the axis of the punch 22 and the distance between the two There is a distance between them to form a ring-shaped pressure regulating groove 25, and a stripping ring 24 is slidably connected in the pressure regulating groove 25. The end surface of the stripping ring 24 is provided with a ring groove 242, which is used to install the limit aluminum sheet 30.

[0050] An air inlet passage 211 is also opened in the lower mold connecting plate 21 , one end of the air inlet passage 211 communicates with the pressure regulating tank 25 , and the other end is connected with an air compressor for applying pressure to the pressure regulating groove 25 . The stripping ring 2...

Embodiment 2

[0062] A method for producing an aluminum soup pot 50 with pot ears 52 using the mold of Embodiment 1. see Figure 7 and Figure 8 The aluminum soup pot 50 in this embodiment includes a pot body 51 and two pot ears 52 disposed on the pot body 51 , and the pot ears 52 and the pot body 51 are integrally formed.

[0063] The production method of the present invention is described in detail below:

[0064] 1) Select the appropriate aluminum sheet 30 according to the pot type, and cut the aluminum sheet 30 into the required size for later use.

[0065] 2) Open the upper mold 10 and the lower mold 20, connect the air compressor to the air inlet channel 211, adjust the outlet pressure of the air compressor according to the specifications of the soup pot to be processed, the size and thickness of the pressure edge of the pot ear 52, and select the pressure adjustment The pressure in the groove 25 , the stripping ring 24 gradually rises under the action of air pressure until the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com