Intramode high-speed precision full-automatic tapping die structure and tapping method thereof

A fully automatic and high-speed technology, applied in the field of tapping, can solve the problems of prolonged product completion cycle and waste of labor cost, and achieve the effect of saving site cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

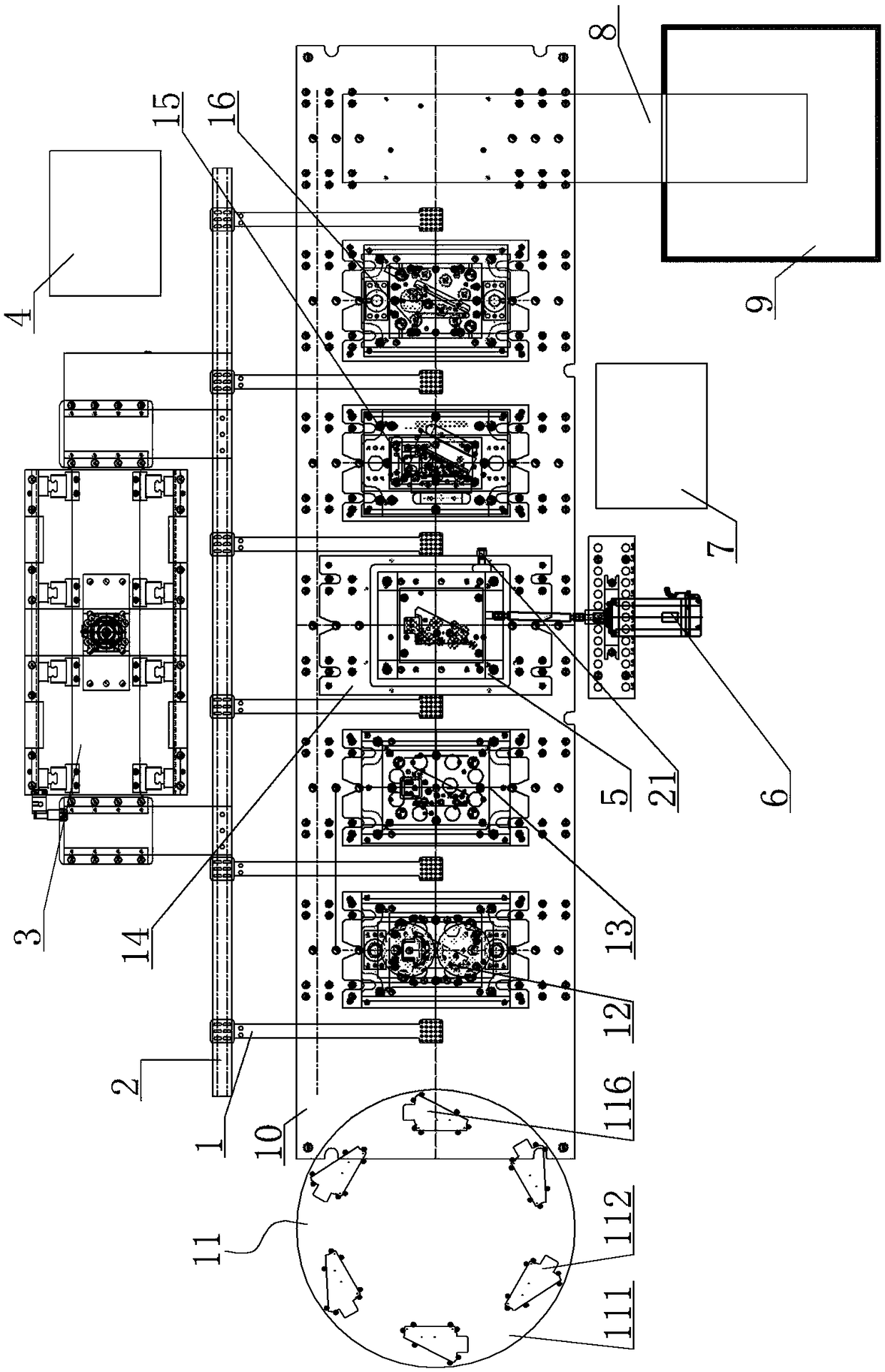

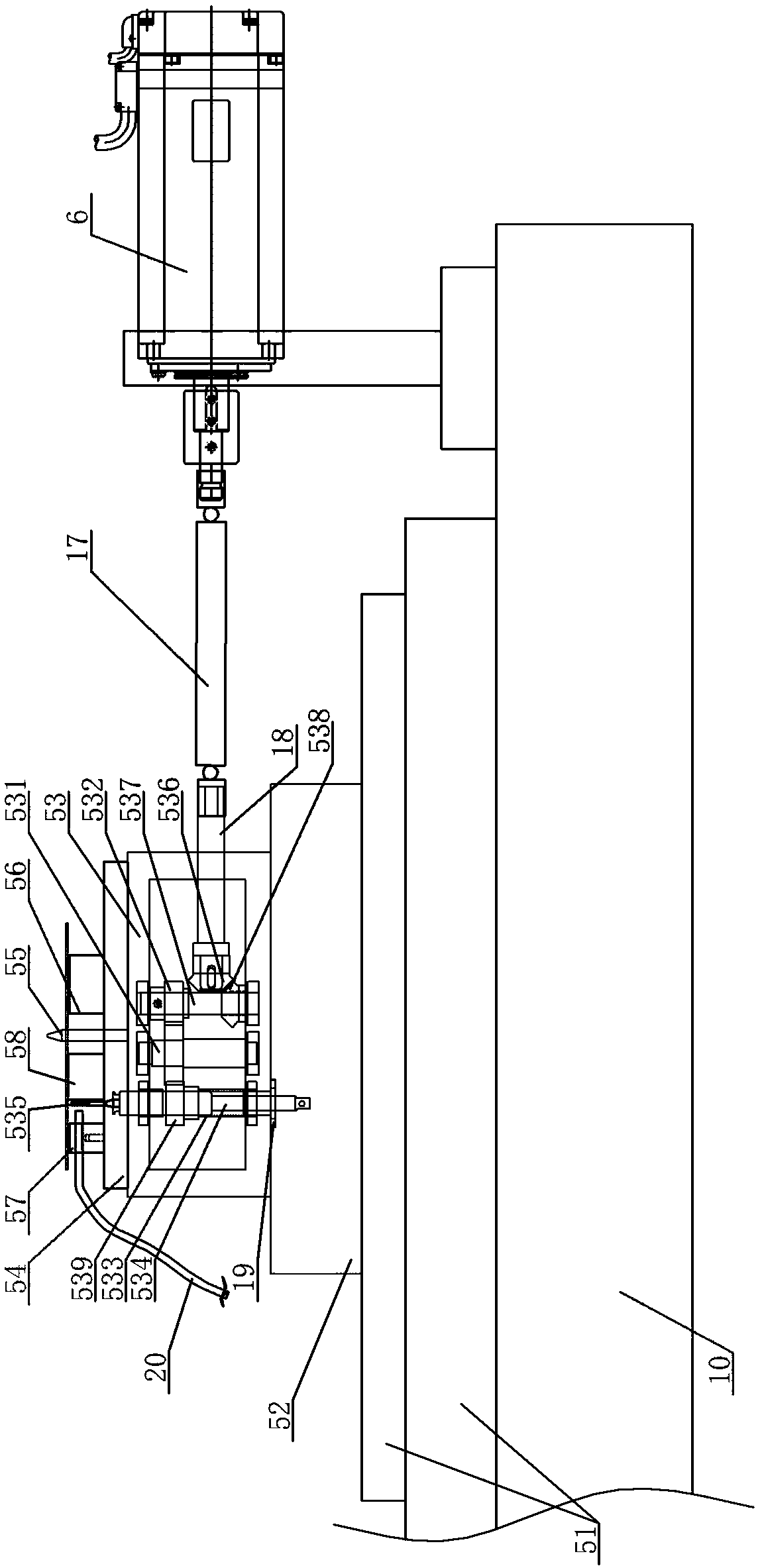

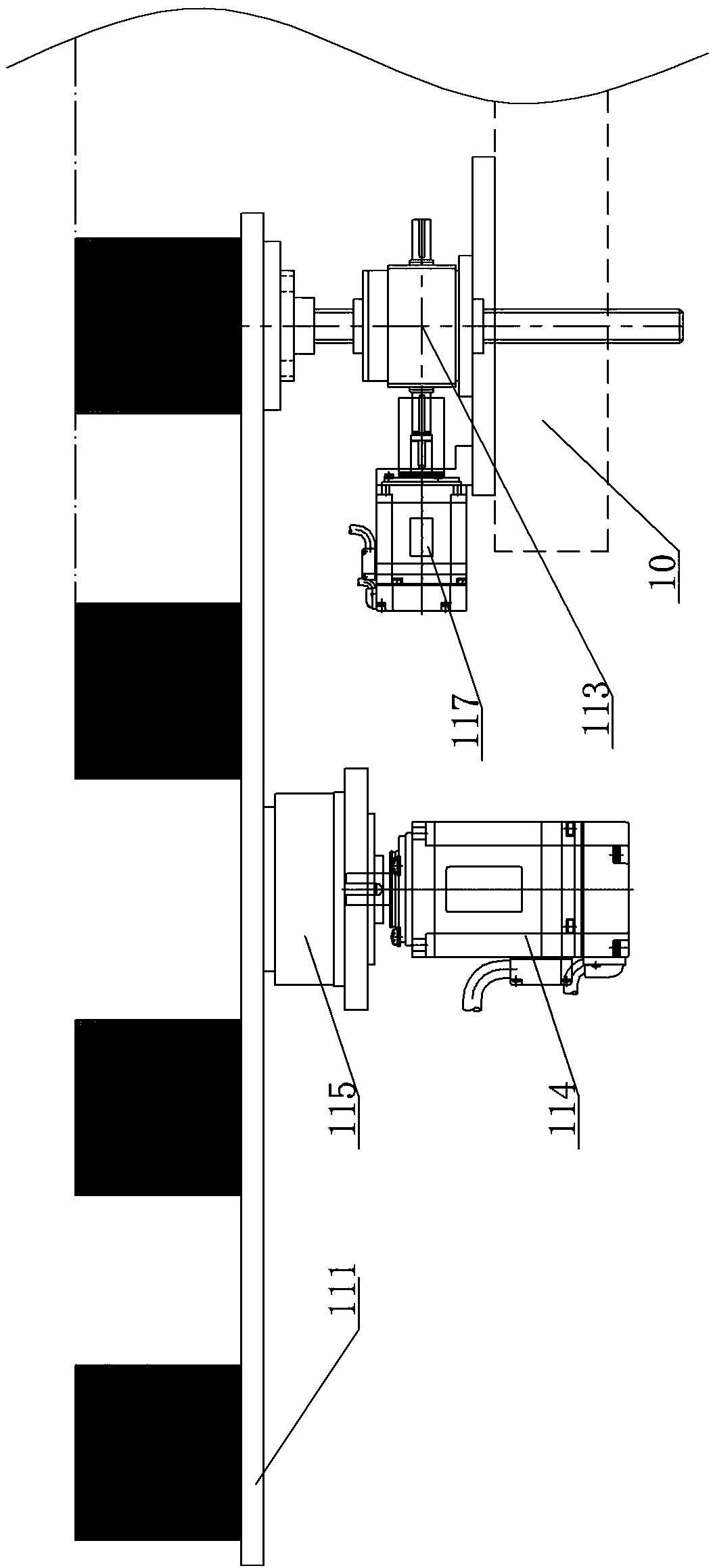

[0030] In-mold high-speed precision automatic tapping die structure, see Figure 1-Figure 3 : It includes a multi-station stamping production line. The multi-station stamping production line includes a feeding station, at least one front stamping station, a tapping station, and a tapping hole detection station. The bases of all stations are Arranged on the punch table, each station is equipped with a mechanical arm 1, and all the mechanical arms 1 are externally connected to a drive shaft 2, the drive shaft 2 is connected to the output end of the drive assembly 3, and the drive assembly 3 is connected to the second A PLC control electric box 4, the tapping station includes a positioning structure and a tapping machine, the input end of the tapping machine 5 is connected to a servo motor 6, and the servo motor 6 and the tapping machine 5 are connected to a second PLC control electric box 7 , a slide plate 8 is arranged behind the end station of the punch table, and the slide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com