A Tool Setting Device for Milling Keyway

A tool setting device and keyway technology, applied in feeding devices, automatic control devices, milling machine equipment, etc., can solve the problems of poor control of tool setting accuracy, cumbersome operation process, and affecting production efficiency, and achieve easy promotion and use, and tool setting The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

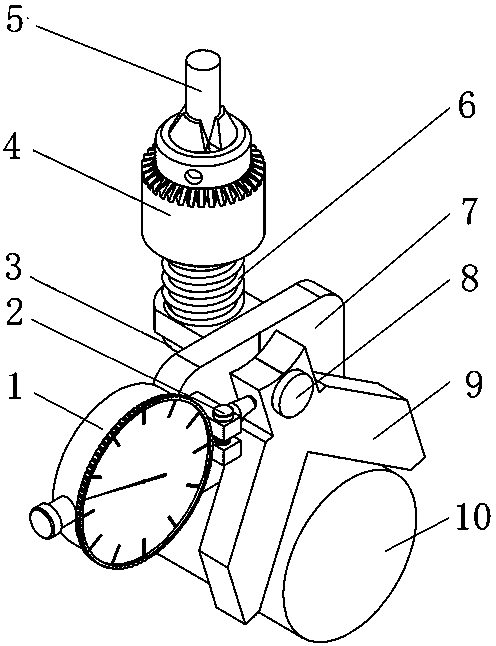

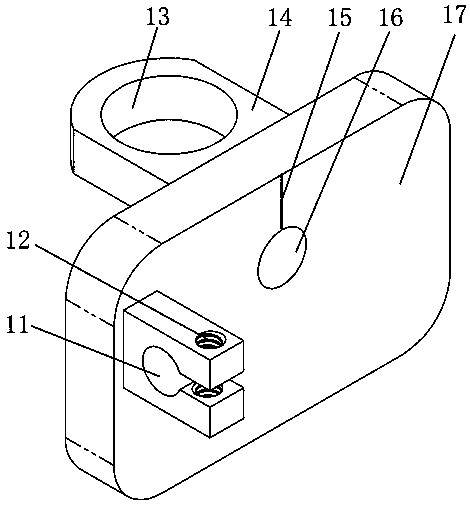

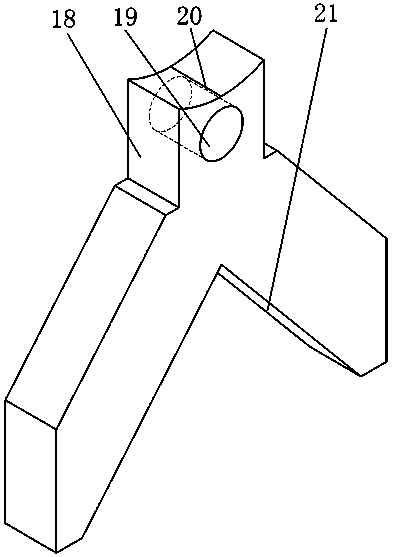

[0031] combine Figure 1~Figure 6 It can be seen that a tool setting device for milling a keyway of the present invention includes a vertical plate 7 fixed below the milling cutter 5 of the milling machine, one side end surface of the vertical plate 7 is oscillatingly connected with a pendulum plate 9, and the pendulum plate 9 The bottom is provided with a "V"-shaped groove 21, and the top of the swing plate 9 is connected to the vertical plate 7 through a swing shaft 8. The axis of the swing shaft 8 is located at the bisector of the included angle of the "V"-shaped groove 21. On the straight line, the vertical plate 7 is provided with a reference line structure 15, and the top of the pendulum plate 9 is provided with a knife setting line structure 20 corresponding to the reference line structure 15, and the reference line structure 15 is located in a "V"-shaped groove 21 On the straight line where the bisector of the included angle is located, the tool alignment structure 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com