Thermoplastic one-way belt production device and method

A technology of production equipment and production method, applied in the direction of coating, etc., can solve the problems of small adjustment range of fiber content, easy warping, uneven gram weight of thermoplastic unidirectional tape, etc., to achieve stable and uniform impregnation pressure, small fiber damage, Improve the effect of warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

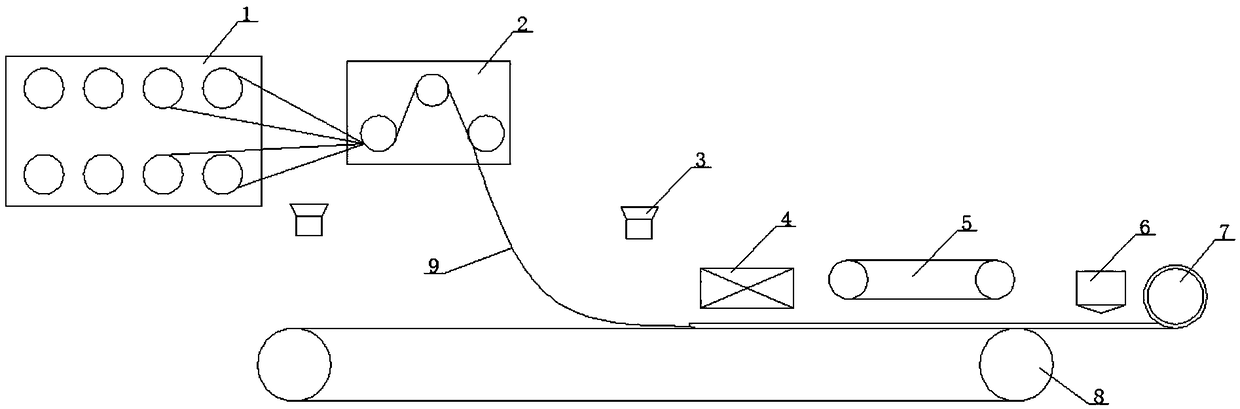

[0027] Such as figure 1 as shown, figure 1 It is a structural view of the thermoplastic unidirectional tape production equipment of the present invention; the thermoplastic unidirectional tape production equipment of the present invention includes a creel 1, a yarn spreading device 2, a powder spreading device 3, a heating device 4, a pressing device 5, a closing device Roll section 7 and support roller table 8.

[0028] The support roller table 8 is arranged between the spreading device 2 and the winding part 7, and the two ends of the reinforced continuous fiber 9 are respectively arranged on the creel 1 and the winding part 7, and the The reinforced continuous fiber 9 is driven out from the creel 1 and further moved to the supporting roller table 8 through the yarn spreading device 2, so as to realize the movement of the reinforced continuous fiber 9. The supporting roller table 8 is provided with a working belt, and during the working process, the working belt moves simu...

Embodiment 2

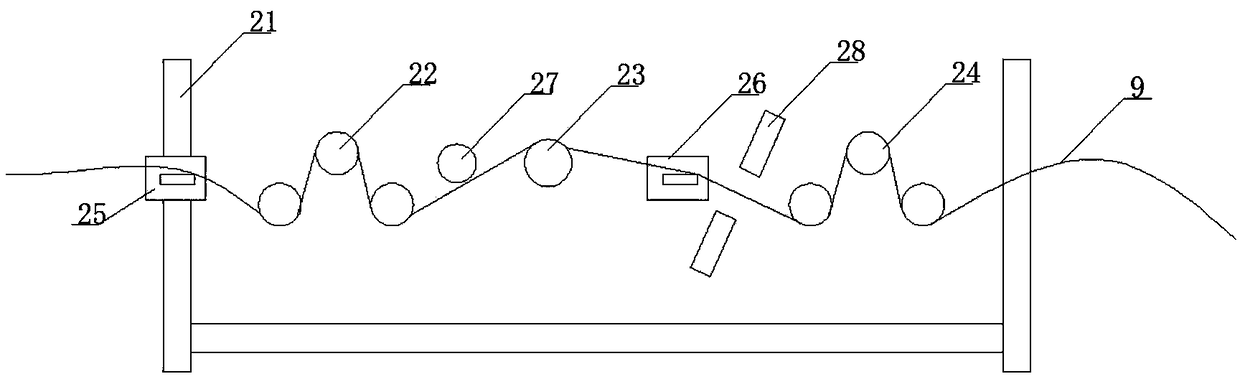

[0043] Such as figure 2 as shown, figure 2 It is a structural view of the spreading device of the present invention. Preferably, the yarn spreading device 2 includes a frame 21 and a power part, and the frame 21 is provided with a front guide roller group 22 and a middle guide roller group in parallel along the direction from the creel 1 to the heating device 4. 23 and the rear guide roller set 24, the front guide roller set 22, the middle guide roller set 23 and the rear guide roller set 24 are all provided with some guide rollers, and the power part drives the guide rollers to rotate so as to realize Enhanced continuous fiber 9 spreading operation.

[0044] The front end of the front guide roller group 22 is provided with a first fiber comb 25 distributed along the axial direction of the front guide roller group 22, between the middle guide roller group 23 and the rear guide roller group 24 is provided with a The second fiber comb 26 distributed in the axial direction o...

Embodiment 3

[0055] The production method of thermoplastic unidirectional tape of the present invention comprises steps:

[0056] S1, fixing the reinforced continuous fiber 9 on the creel 1, and driving the reinforced continuous fiber 9 to move through the yarn spreading device 2;

[0057] S2, the powder spreading device 3 is turned on and evenly spreads resin powder on the surface of the reinforced continuous fiber 9 moved out from the spreading device;

[0058] S3, the reinforced continuous fiber 9 is subjected to heat treatment and impregnation treatment;

[0059] S4, the reinforced continuous fiber 9 after impregnation treatment is preliminarily shaped by the pressing device 5 , and then cut and wound by the cutting device 6 .

[0060] Step S1 specifically includes: placing each of the reinforcing continuous fibers 9 on the creel 1 according to the design. A number of unwinding rollers are arranged on the creel 1, and the reinforced continuous fiber 9 is arranged on the unwinding rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com