Core-pulling pipe embosser and split-type mold core set

A split-type, embossing technology, applied in decorative arts, embossed ornaments, etc., can solve problems such as low embossing efficiency, reduce deformation and avoid scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

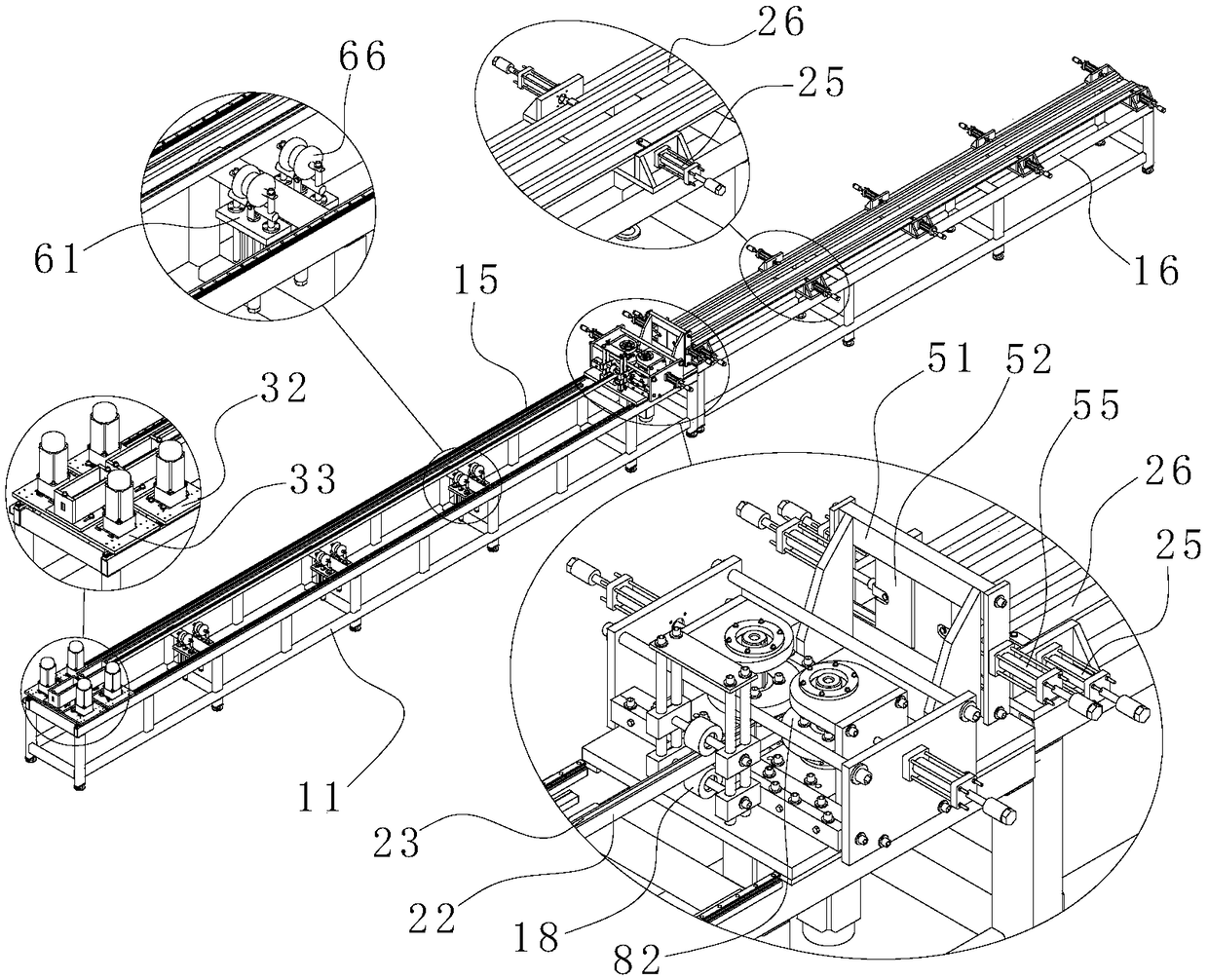

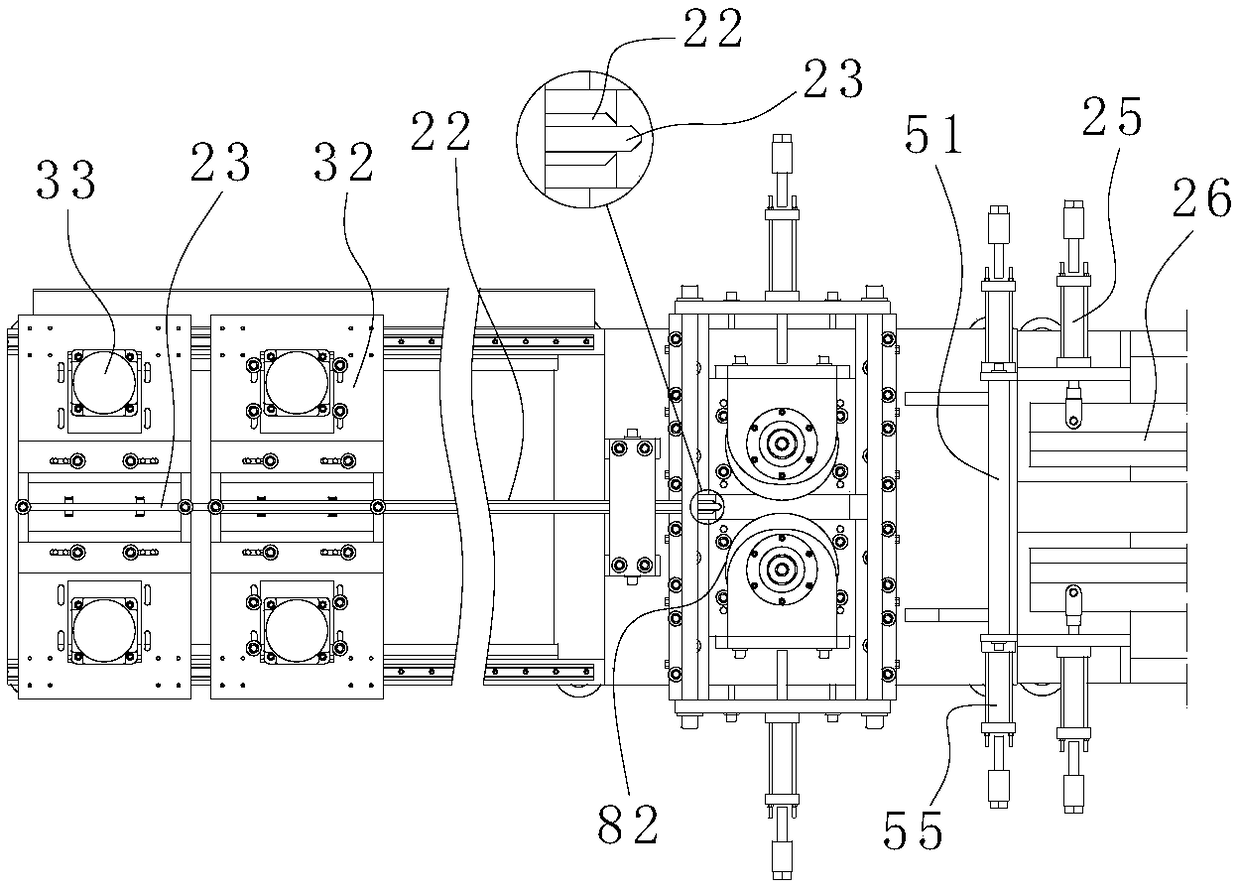

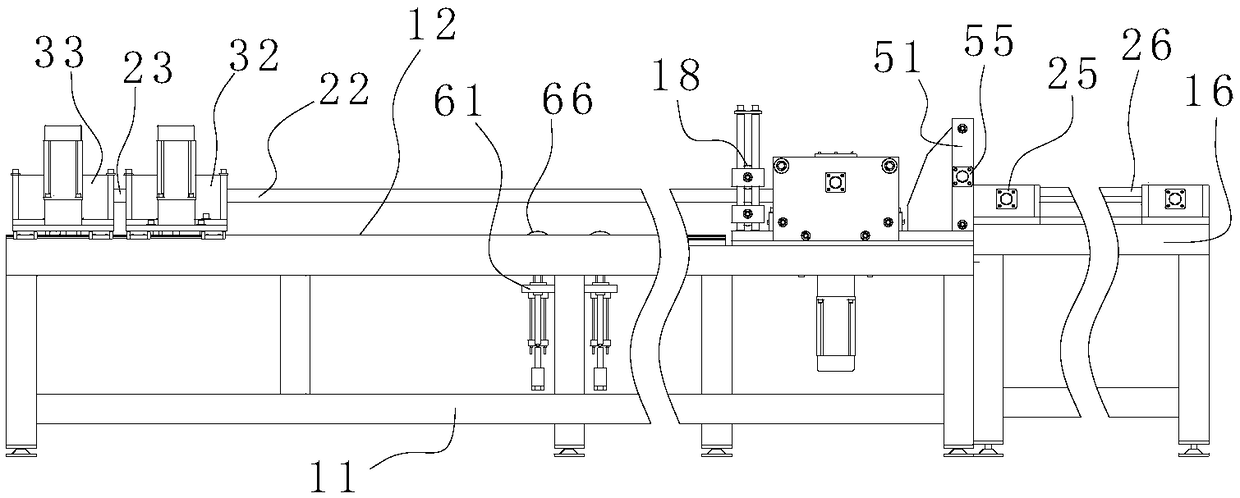

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 , Figure 5 As shown, a core-pulling pipe embossing equipment of the present invention includes a split-type core set that can be pulled out step by step. The side where the embossing stamp of the core 22 is forced to be close to the inner support core 23 on the inner side of the pipe to be embossed. Both the core 22 and the inner support core 23 are inserted into the pipe to be embossed to support the inner surface of the pipe to be embossed, and the outer pressure is applied to press the pattern on the pipe wall, and the pattern is deformed on the inner side of the pipe wall and recessed into the core 22 The core 22 cannot be drawn out directly in the die print; the split core set is used, and the inner support core 23 is drawn out first, so that it is easier to form a gap between the core 22 and the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com