Continuous type regenerative braking system

A regenerative braking and rope technology, applied in sustainable transportation, climate sustainability, railway transportation, etc., can solve the problems of high stability requirements, large regenerative braking strokes, and difficult clutching, and achieve high stability requirements. , The effect of large regenerative braking stroke and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

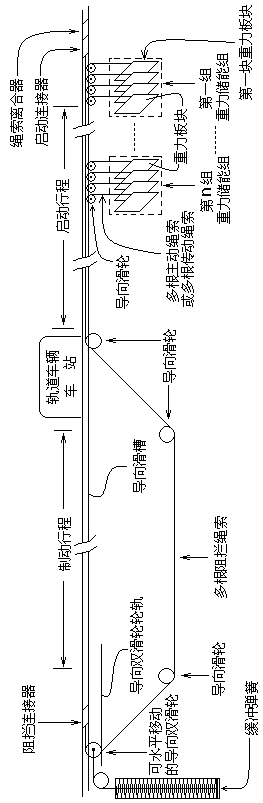

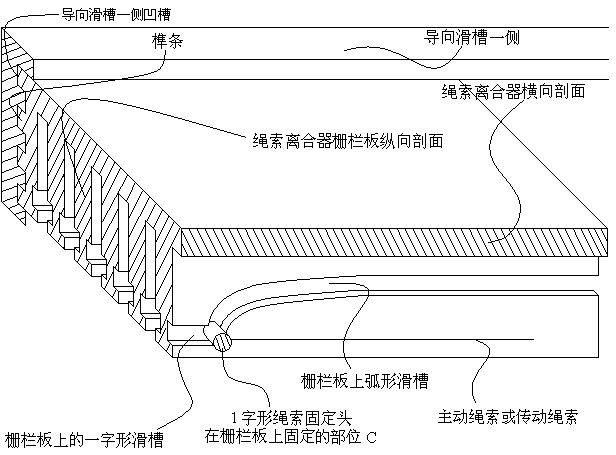

[0019] On the implementation of multi-rope crossover clutches in guide chutes. During the braking process, the multi-rope cross-connection clutch implements clutching between a transmission rope, a 2-shaped rope pile and the rope clutch. The one-shaped rope fixing head of a transmission rope is fixed on the A part of the two-shaped rope pile (such as Figure 6 ), when the rope clutch slides along the guide chute to the braking direction (such as Figure 4 ), the 2-shaped rope stake enters the rope clutch fence plate (such as Figure 7 ), the 1-shaped rope fixing head fixed on the A part of the 2-shaped rope pile enters the inline chute of the rope clutch, and is fixed on the C part of the rope clutch. When the rope clutch continued to slide towards the braking direction along the guide chute, the rope clutch would take the inline rope fixing head away from the 2-shaped rope pile, that is, the root drive rope was connected with the rope clutch.

[0020] Then, the multi-rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com