Renewable desulfurizing agent

A technology of desulfurization agent and modified carbon, which is applied in the direction of filter regeneration, combustible gas purification, combustible gas purification/transformation, etc. It can solve the problems that the adsorbent cannot be recycled and reused, the regeneration of the adsorbent is difficult, and the stability is poor, so as to promote Effects of contact, improvement of stability, and improvement of adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

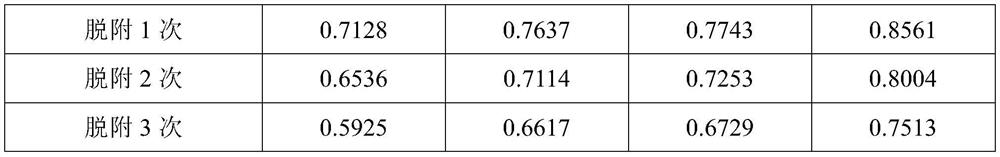

Embodiment 1

[0030] A renewable desulfurizer, the desulfurizer is a modified carbon composite metal organic framework material, and a preparation method thereof comprises the following steps:

[0031] S1. Preparation of modified carbon

[0032] Weigh 4 g of tetraethylene pentamine and disperse it in 100 mL of acetone solvent, stir until fully dissolved, add 8 g of activated carbon micropowder while stirring at room temperature, heat up to 40-50 ° C, continue to stir until dry, and obtain after drying. modified carbon;

[0033] Preparation of S2, tetracarboxylic acid ligands

[0034] Weigh 2.2 g of methyl p-hydroxybenzoate and 1.2 g of tetrabromopentane, respectively, and dissolve them in 100 mL of dimethylformamide. After fully stirring and dissolving, add 10 g of potassium carbonate, stir and heat up to 120-130° C. The reaction was kept stirring for 48-60h under a protective atmosphere. After the reaction was completed, it was cooled to room temperature and diluted with excess deionized...

Embodiment 2

[0039] A kind of renewable desulfurizing agent, its preparation method comprises the following steps:

[0040] S1. Preparation of modified carbon

[0041] Weigh 4 g of tetraethylene pentamine and disperse it in 100 mL of acetone solvent, stir until fully dissolved, add 8 g of activated carbon micropowder while stirring at room temperature, heat up to 40-50 ° C, continue to stir until dry, and obtain after drying. modified carbon;

[0042] S2. Preparation of copper metal particles

[0043] Weigh 2g of polyvinylpyrrolidone (Mw=5500) and dissolve it in 100mL of ethylene glycol, add 0.5g of copper chloride, stir and dissolve fully, then heat up to 170-180°C and keep warm for 10-20min, add acetone to dilute after the insulation is completed , separate the precipitate and wash it with acetone to obtain the copper metal particles;

[0044] Preparation of S3 and tetracarboxylic acid ligands

[0045]Weigh 2.2 g of methyl p-hydroxybenzoate and 1.2 g of tetrabromopentane, respectivel...

Embodiment 3

[0050] A renewable desulfurizer loaded with ionic liquid;

[0051] The preparation method of the desulfurizer loaded with ionic liquid comprises the following steps:

[0052] (1) 4 g of 1,2,4,5-tetrakis(bromomethyl)benzene, 3.6 g of 1-vinylimidazole and 0.2 g of 2,6-di-tert-butyl-p-cresol were weighed and dissolved in 200 mL of acetonitrile solvent After fully stirring and dissolving, the temperature was raised to 60-70°C and the reaction was stirred and refluxed for 48-60h. After the reaction was completed, the precipitation was separated, washed and dried in vacuo to obtain the monomer 1,2,4,5-tetrakis(1'-methylene). yl-3'-vinylimidazolium bromide) benzene;

[0053] (2) Dispersing and dissolving the monomer obtained in step (1) in methanol or ethanol solution to prepare a monomer solution with a concentration of 8 g / L, and immersing the desulfurizing agent obtained in Example 1 in the monomer solution In the bulk solution, fully stirred and mixed, heated to 40-50° C., soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com