Voltage sensor and method for measuring voltage using the same

A voltage sensor and a technology for measuring voltage, applied in the field of sensors, can solve the problems of high cost, high requirements on polarization stability of light source and optical path system, poor temperature stability and environmental stability, and achieve low cost, high stability, adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

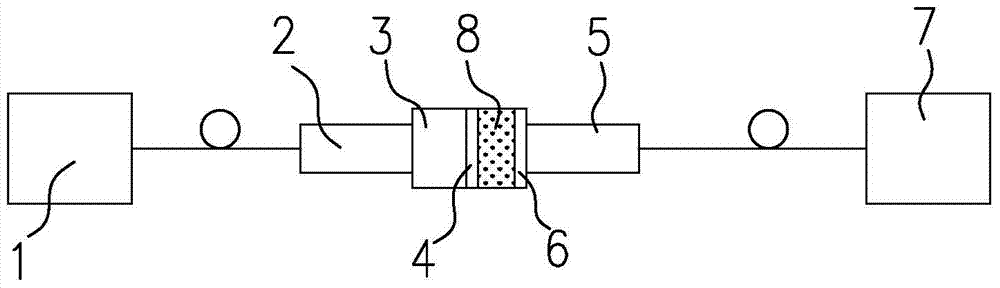

[0023] Such as figure 2 As shown, the voltage sensor of the present invention includes a monochromatic non-polarized light source 1, a first converging lens 2, an electro-optic sensor 3, a polarizer 4, a second converging lens 5, an aperture 6 and a photodetector 7, and a monochromatic non-polarized light source 1 The first converging lens 2 is connected by a multimode optical fiber, the first converging lens 2 is fixed on one side of the electro-optic sensor 3 by glue bonding, the other side of the electro-optic sensor 3 and one side of the polarizer 4 are fixed by glue bonding, and the polarizer The other side of the 4 is bonded and fixed with quartz glass 8, the other side of the quartz glass 8 is bonded and fixed with the diaphragm 6, and the other side of the diaphragm 6 is fixed with one side of the second converging lens 5 by glue bonding. The other sides of the two converging lenses 5 are connected to the photodetector 7 through another multimode optical fiber.

[00...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that the positions of the diaphragm 6 and the second converging lens 5 are exchanged, the other side of the polarizer 4 is bonded and fixed with quartz glass 8, and the other side of the quartz glass 8 is bonded and fixed with the second Two converging lenses 5, the other side of the second converging lens 5 is bonded and fixed to one side of the diaphragm 6, and the other side of the diaphragm 6 is connected to the photodetector 7 through an optical fiber.

[0027] The present invention adopts the method for measuring voltage of above-mentioned voltage sensor, comprises the following steps:

[0028] (1) load the voltage to be measured on the electro-optic sensor 3,

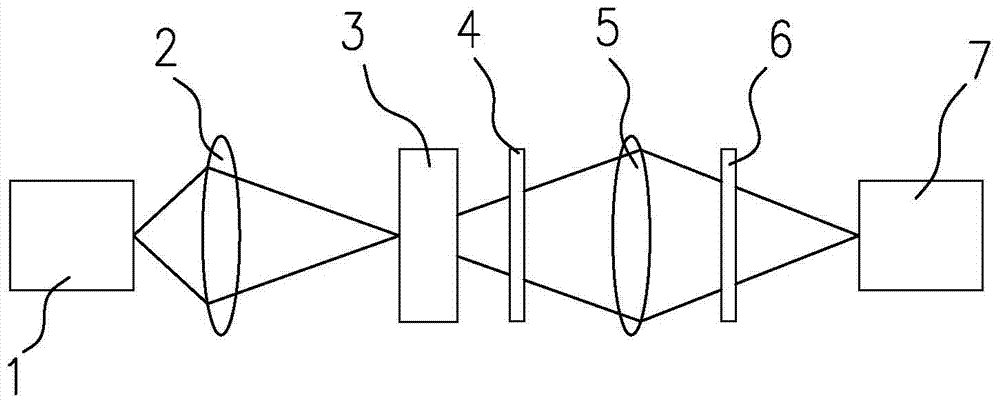

[0029] (2) if figure 1 As shown, the light beam emitted by the monochromatic non-polarized light source 1 passes through the first converging lens 2 to form a converging light beam with a convergence angle of 30°-70° and enters the electro-optic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com