Compound double-layered glass cement barrel

A composite double-layer, plastic cartridge technology, applied to rigid containers, containers, packaging, etc., can solve the problems of consuming a lot of manpower, material resources, financial resources and transportation resources, high sealing performance requirements, and natural environment pollution, and achieve optimal utilization. , reliable quality, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

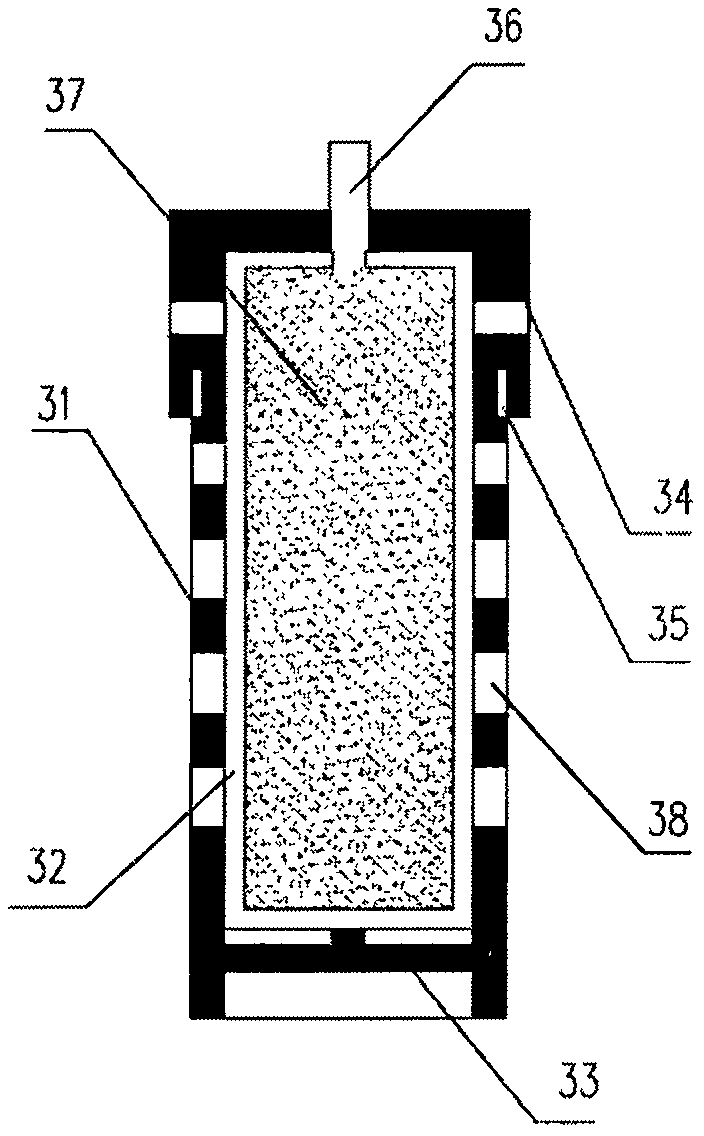

[0034] Such as figure 1 As shown, a composite double-layer rubber cartridge includes a hard rubber cartridge and a soft rubber cartridge 32; the hard rubber cartridge includes a hollow body 31, a head 34 and a bottom cover 33; the soft rubber cartridge 32 is equipped with glass glue 37 and is placed inside the hard rubber tube; the hollowed-out cylinder body 31 is made of metal alloy material, and the described sealing head 34 is made of plastic material; the described sealing head 34 is connected with the hard rubber tube by thread 35 Way.

[0035] The sealing head 34 is provided with a glue outlet 36. When in use, open the sealing port 34 and the upper sealing port of the soft rubber tube 32, then close the sealing head 34 and the hollow body 31 of the hard rubber tube, and push the bottom cover 33 through the driving device. So as to achieve the purpose of sizing operations.

[0036] The soft rubber tube 32 is filled with glass glue 37, sealed well and closely attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com