A kind of aluminum oxide ceramic matrix composite material honeycomb and preparation method thereof

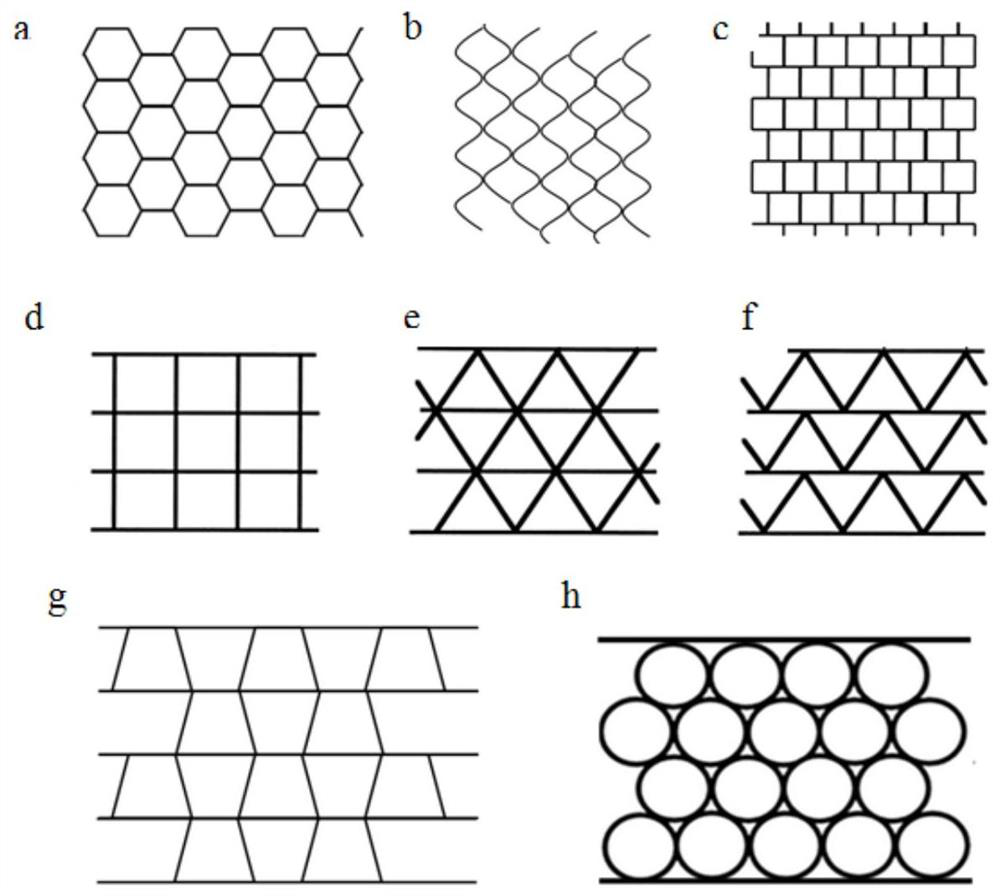

A technology of alumina ceramics and composite materials, which is applied in the field of inorganic materials, can solve the problems of low operating temperature and achieve the effects of good temperature resistance, high temperature resistance, and adjustable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

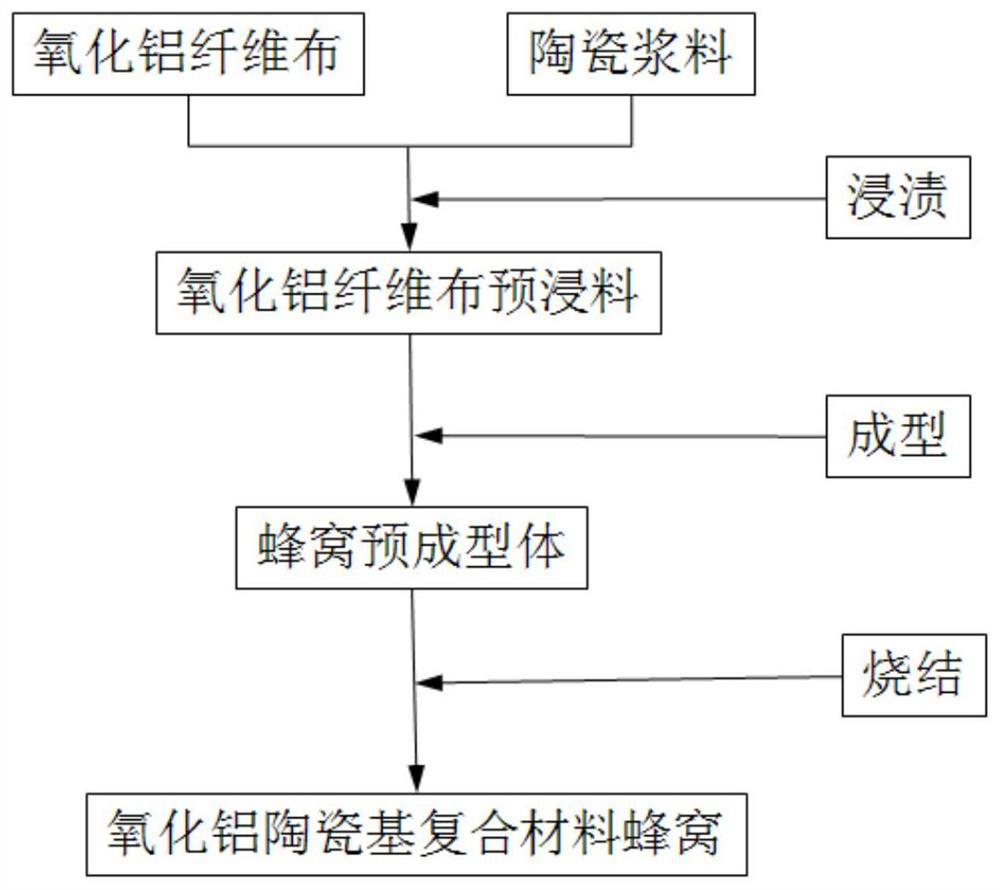

[0041] A method for preparing an alumina ceramic matrix composite material honeycomb, the specific steps are:

[0042] (1) Mix ceramic powder, sol, and organic additives in proportion, and obtain a uniform slurry after ball milling; the mass fraction of ceramic powder, sol, and additives is: (20-80%): (20-40% ): (0~20%)

[0043] (2) impregnating alumina fiber cloth with the above ceramic slurry to form a prepreg;

[0044] (3) According to the design thickness of the honeycomb skeleton, the multi-layer alumina fiber cloth prefabricated body is stacked together;

[0045] (4) Put the stacked alumina fiber cloth prefabricated body into the mold, and then heat and solidify to form;

[0046] (5) After the solidified alumina fiber cloth prefabricated body is demolded, it is bonded together with a high-temperature adhesive to form a honeycomb preformed body; the bonding surface is determined by the shape of the honeycomb;

[0047] (6) Put the honeycomb preform into a high-temperatu...

Embodiment 1

[0061] A preparation method of alumina ceramic matrix composite material honeycomb, such as figure 2 As shown, the steps of the method include:

[0062] (1) 80g of alumina powder, 8g of silica sol, 32g of polyvinylpyrrolidone solution and 0.1g of nitric acid were mixed, and ball milled on a ball mill for 12 hours to obtain a ceramic slurry;

[0063] (2) above-mentioned ceramic slurry is brushed on the surface of Nextel610 alumina fiber cloth, obtains alumina fiber cloth prepreg;

[0064] (3) Cut the alumina fiber prepreg into cloth strips with a width of 2cm, stack them together, put them into a mold, heat and cure them at 80°C; the shape of the mold is semi-hexagonal, and the side length of the hexagon is 1cm;

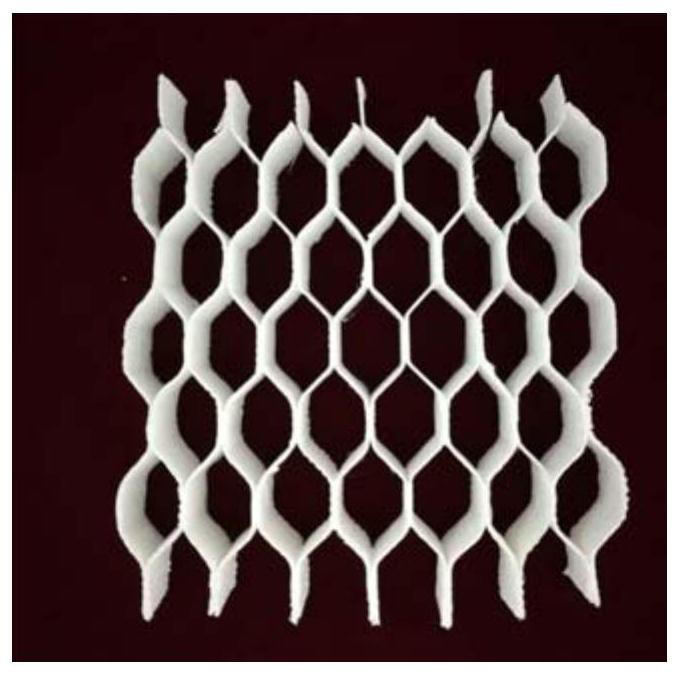

[0065] (4) After demoulding, the formed alumina fiber cloth prefabricated body is bonded together with ceramic slurry to obtain the alumina ceramic matrix composite material honeycomb preformed body, and the honeycomb hole shape is a regular hexagon;

[0066] (5) ...

Embodiment 2

[0069] (1) 100g of alumina powder, 20g of aluminum sol, 45g of polyethylene glycol solution and 0.25g of nitric acid were mixed, and ball milled on a ball mill for 24 hours to obtain a ceramic slurry;

[0070] (2) above-mentioned ceramic slurry is brushed on the surface of Nextel720 alumina fiber cloth, obtains alumina fiber cloth prepreg;

[0071] (3) Cut the alumina fiber prepreg into cloth strips with a width of 1cm, stack them together, put them into the mold, and heat and cure them at 100°C; the shape of the mold is semi-hexagonal, and the side length of the hexagon 1cm;

[0072] (4) After demoulding, the formed alumina fiber cloth prefabricated body is bonded together with ceramic slurry to obtain the alumina ceramic matrix composite material honeycomb preformed body, and the honeycomb hole shape is hexagonal;

[0073] The ceramic slurry is mixed with 10g of alumina, 2g of silicon oxide, 1g of boron oxide, 1.2g of calcium oxide and 15g of polyethylene glycol solution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com