Finishing paint for button, colored finishing paint for button and preparation method of button

A topcoat and button technology, applied in the field of buttons, can solve the problems of poor button film protection, poor resistance to washing, dry cleaning and ironing, and easy detachment of the side film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

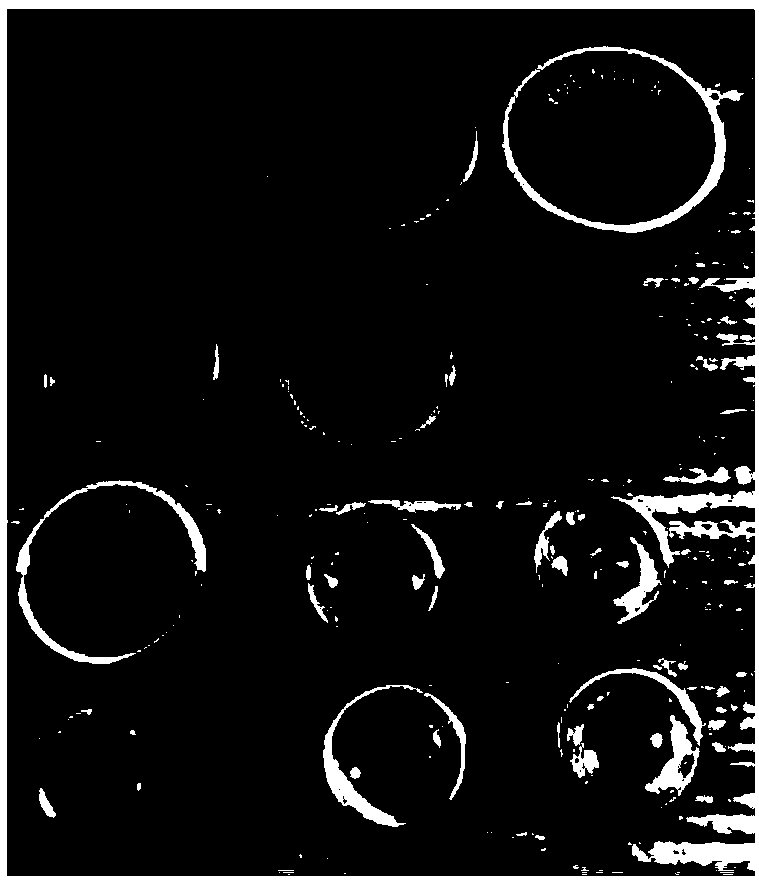

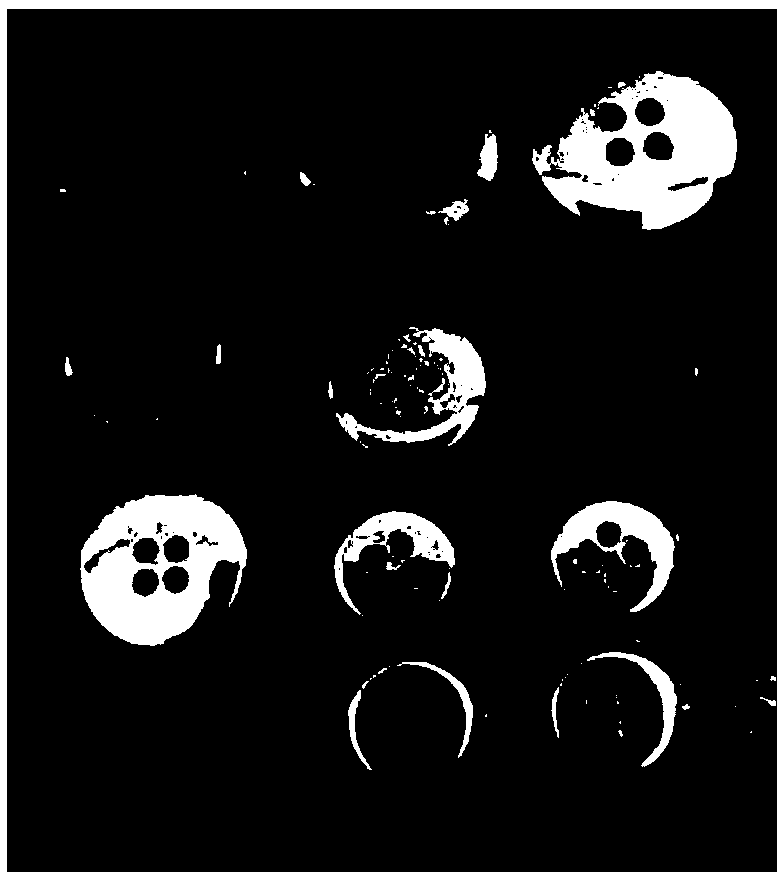

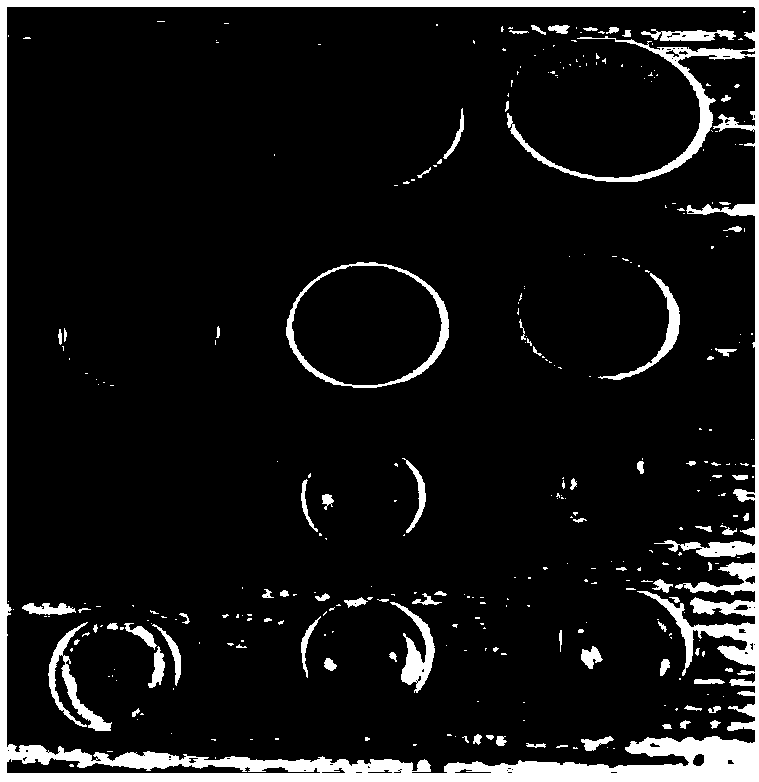

Image

Examples

preparation example Construction

[0055] The present invention also provides a kind of preparation method of button, comprises the following steps:

[0056] a) Spraying a primer on the surface of the semi-finished button to obtain a primer button;

[0057] b) coating the primer button to obtain a coated button;

[0058] c) Spraying a topcoat on the coated button to obtain a button;

[0059] The topcoat is the topcoat for buttons described in the above technical solution or the colored topcoat for buttons described in the above technical solution.

[0060] In the present invention, in the step a), the semi-finished button is a button blank. The present invention has no special limitation on the type of the button blank, which can be a well-known button blank in the art, such as a resin button, a natural real shell button, a plastic nylon button or an ABS button. Among them, resin buttons are artificially synthesized buttons, adding accelerators and various functional accessories (such as pearl effect, patter...

Embodiment 1

[0065] Raw materials: polyester acrylic resin YWU3031 55%, ultraviolet absorber UV-329 4%, Tego 21000.7%, Lan Kelu Lencolo 2193 0.3%, solvent (ethyl acetate: isopropanol: isobutanol mass ratio =1:1:1) 40%.

[0066] Preparation of topcoat: add solvent to resin, disperse with high-speed dispersing mixer for 25 minutes, add other raw materials, continue to stir and disperse for 8 minutes, and finally, filter the obtained transparent paint into a special sealed bucket for later use.

[0067] Button preparation: After the button blank is polished, cleaned and dried, it is placed on a supporting fixture and sprayed with a primer (UV polyester acrylic primer UV187, the thickness of the paint film is 10μm), and then coated with a metal film layer, and then the optical fiber laser forms a pattern , and then spray the above-mentioned topcoat (the thickness of the paint film is 15 μm) to obtain a button with a metallic effect on the overall appearance (denoted as S1a).

[0068] Prepared...

Embodiment 2

[0076] Raw materials: polyester acrylic resin YWU3031 65%, ultraviolet absorber UV-329 4.1%, Tego TEGO21000.6%, Lan Kelu Lencolo 2193 0.3%, solvent (mass ratio of ethyl acetate: isopropanol: isobutanol =1:1:1) 30%.

[0077] Preparation of topcoat: add solvent to resin, disperse with high-speed dispersing mixer for 25 minutes, add other raw materials, continue to stir and disperse for 8 minutes, and finally, filter the obtained transparent paint into a special sealed bucket for later use.

[0078] Button preparation: After the button blank is polished, cleaned and dried, it is placed on a supporting fixture and sprayed with a primer (source UV polyester acrylic primer UV187, the thickness of the paint film is 10μm), and then coated with a metal film layer, and then formed by optical fiber laser pattern, and then spray the above-mentioned topcoat (the thickness of the paint film is 15 μm) to obtain a button with a metallic effect on the overall appearance (denoted as S2a).

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com