Method for synchronous construction of variable-spacing double-width bridge by adopting segment assembling bridge erecting machine

A technology of synchronous construction and bridge erecting machine, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of increasing equipment operation risks, inability to realize synchronous construction, and prolonging the construction period, so as to achieve simple structure and save construction time , the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

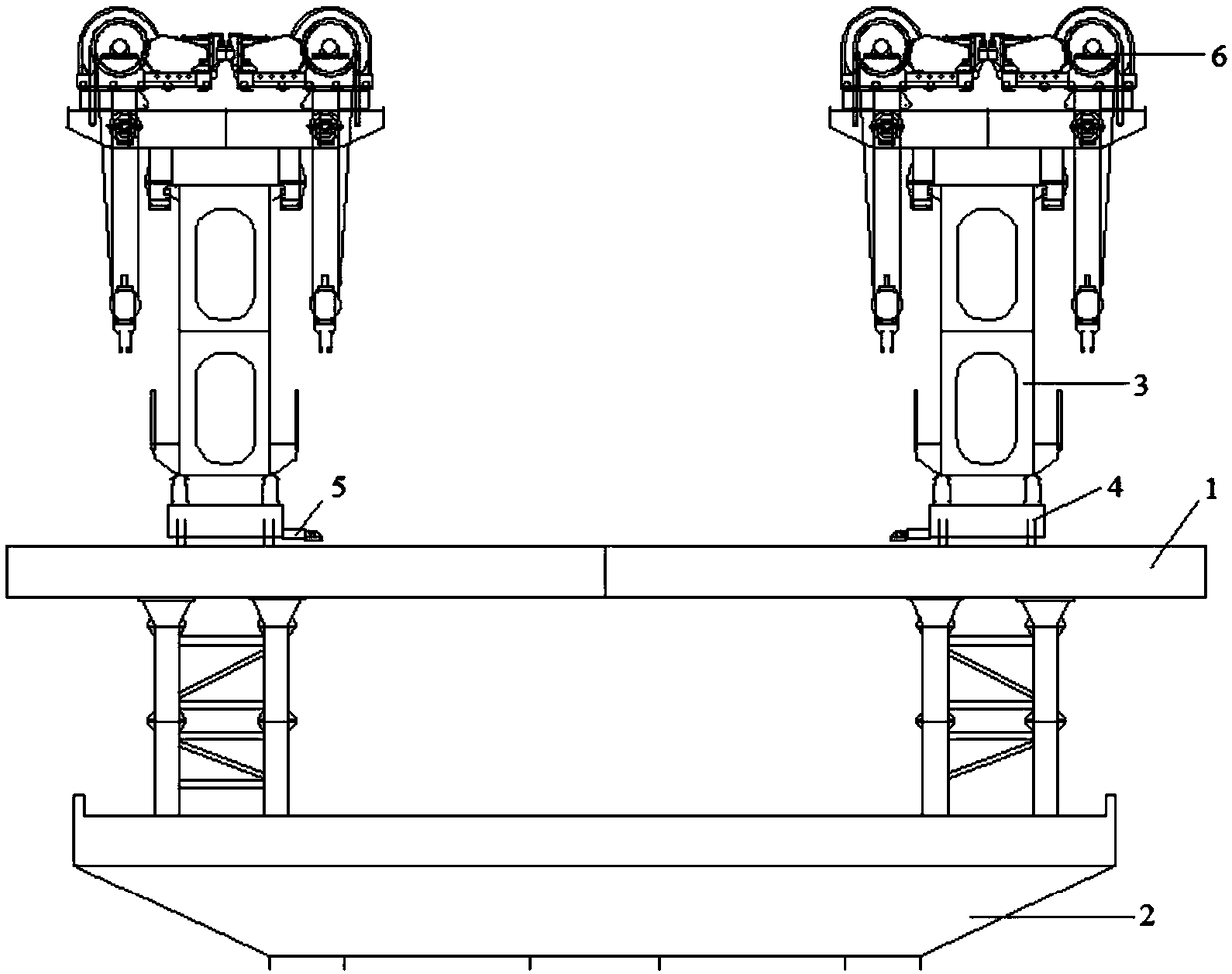

[0089] S1, the bridge erecting machine is erected between the first pier 27 and the second pier 28 along the front end of the longitudinal bridge, and the bridge erecting machine includes:

[0090] A pair of crossbeams 1, its length direction is arranged along the cross bridge direction, and a pair of crossbeams 1 is respectively fixed on the first pier 27 and the second pier 28 that the front end is close to by the column;

[0091] A pair of main girders 3 are arranged at intervals along the longitudinal bridge direction, and a pair of main girders 3 can be erected above the first bridge pier 27 and the second bridge pier 28 slidingly along the longitudinal bridge direction; The middle part of 3 is set on a pair of beams 1 through the trolley 4 below it, which can slide along the direction of the bridge;

[0092] Pushing device 5, which is arranged on the cross beam 1 along the cross bridge direction and corresponds to the trolley 4 one by one, one end of the pushing device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com