Assembled bamboo strip foundation pit protection slope and construction method thereof

A construction method and prefabricated technology, which can be used in basic structure engineering, excavation, construction, etc., can solve the problems of increased construction cost, large amount of materials, and high labor intensity, so as to prevent soil erosion, convenient and flexible operation, and labor intensity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

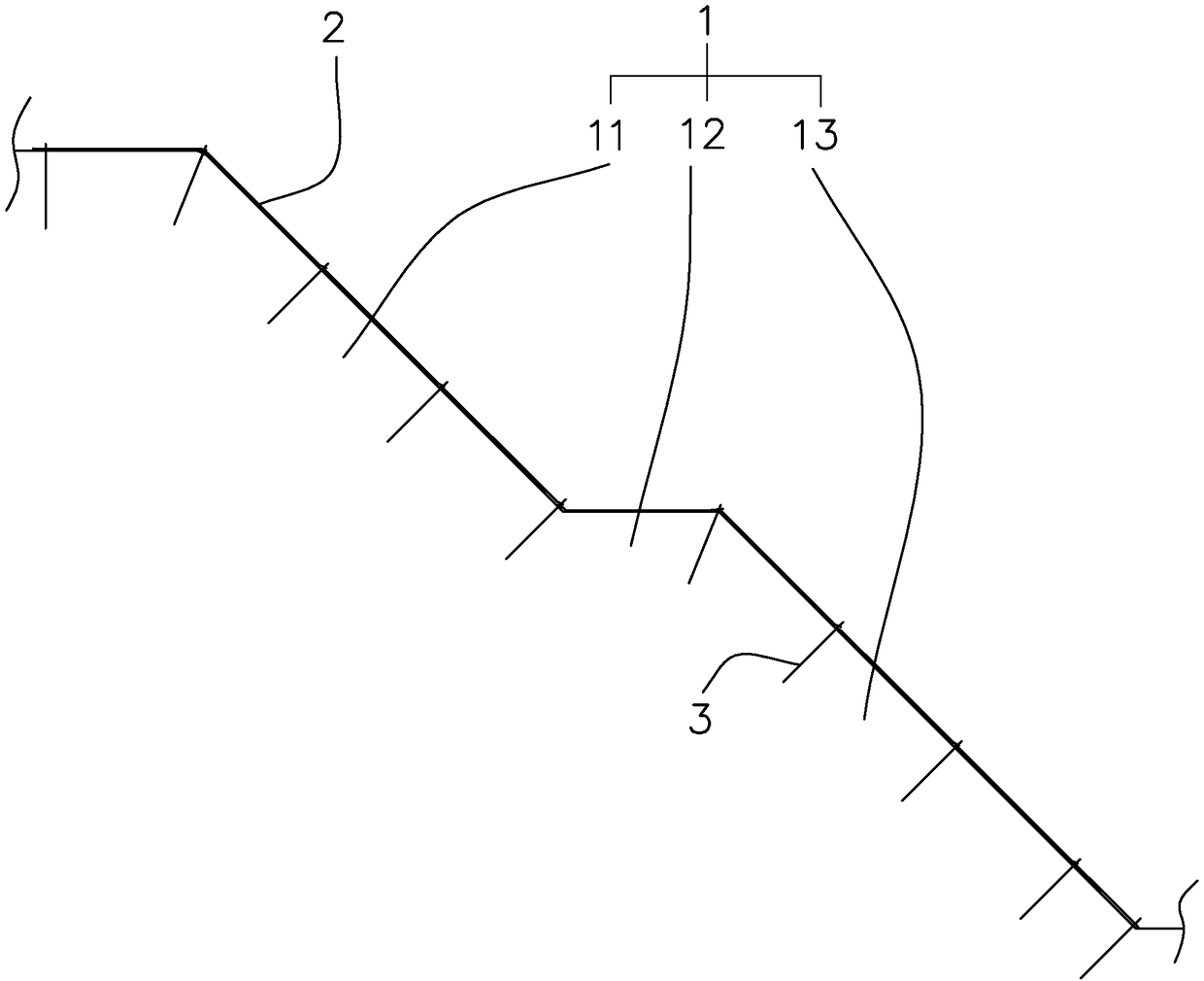

[0045] A kind of prefabricated bamboo strip foundation pit slope protection, such as figure 1 , including a foundation pit 1, and the foundation pit 1 includes an upper soil mass 11, a platform 12 and a lower soil mass 13. Bamboo strips 2 are laid on the foundation pit 1 to protect the upper surface of the foundation pit 1 and prevent soil erosion on the surface of the foundation pit 1 .

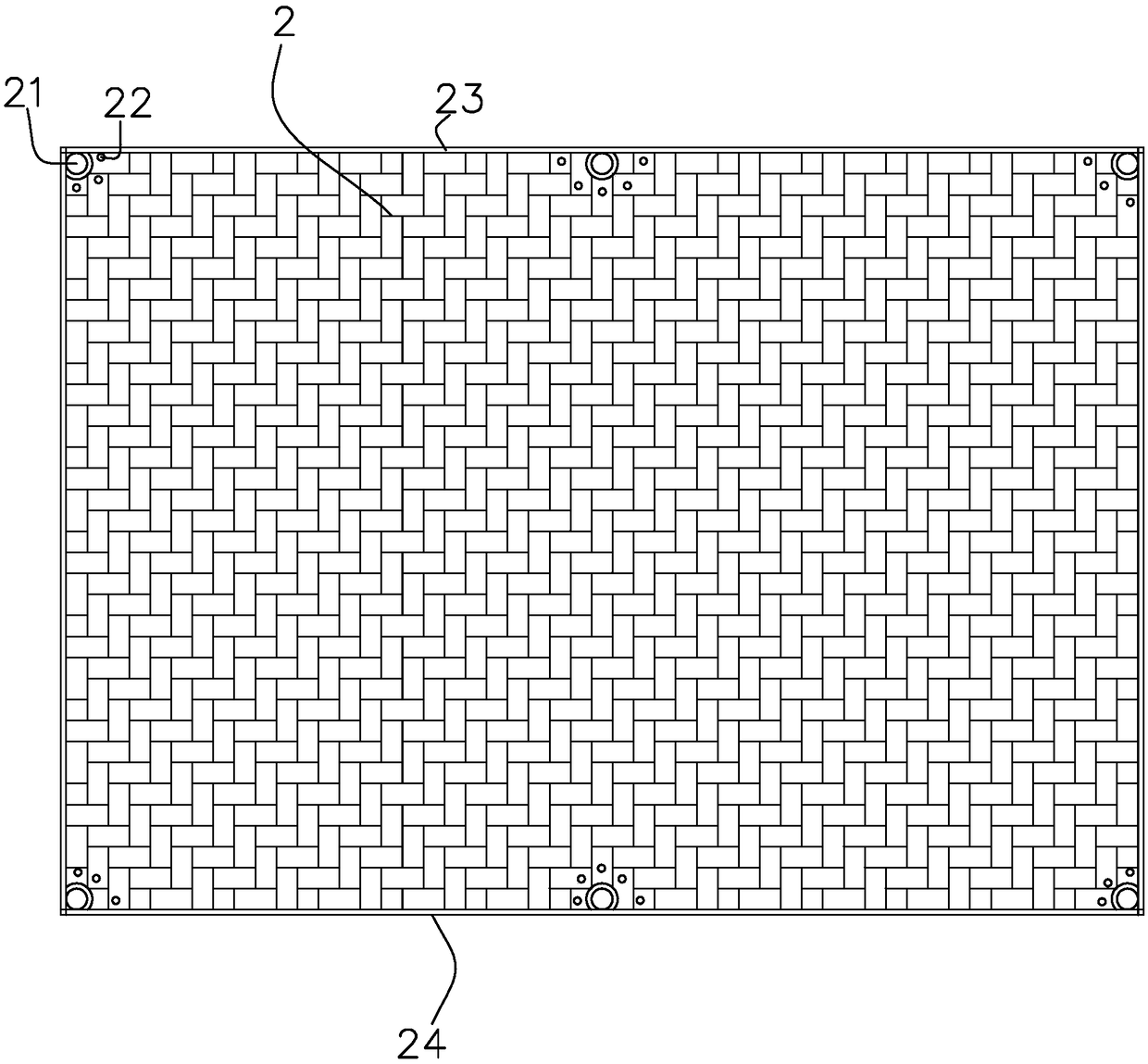

[0046] Such as figure 1 with figure 2 There are several connection holes 21 around the bamboo strip 2, and bamboo nails 3 are inserted in the connection holes 21. The bamboo strip 2 is connected to the foundation pit 1 through the bamboo nails 3, and the bamboo strip 2 is easy to disassemble. The end of bamboo nail 3 is set as pointed, is convenient to the insertion of bamboo nail 3.

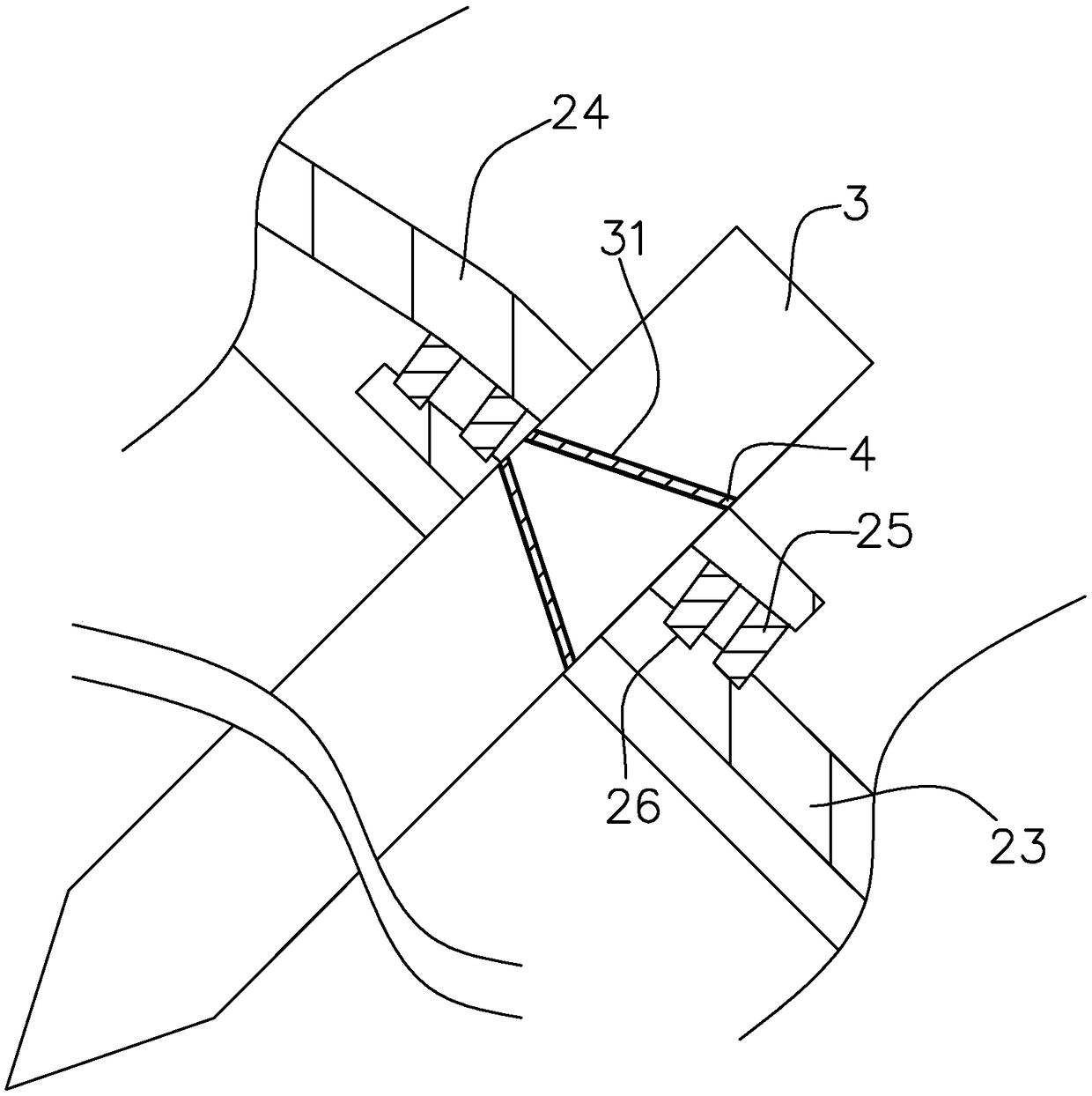

[0047] Such as figure 2 with image 3 , the bamboo strips 2 are provided with some fixing holes 22 near the connection holes 21, and the fixing holes 22 are pierced with tie wires 4, and the tie wires 4...

Embodiment 2

[0053] A construction method for slope protection of a prefabricated bamboo strip foundation pit, comprising the foundation pit 1 and bamboo strips 2 in the first embodiment.

[0054] 1. The production of the assembled bamboo strips 2: raw moso bamboo is used, and the bamboo strips 2 are formed after opening, drawing, cooking, drying, and weaving. The periphery of the bamboo strips 2 is provided with a connecting hole 21 of D50mm, and the specifications of the bamboo strips 2 The size generally adopts (length×width) 120cm×80cm, 120cm×60cm, 120cm×40cm, etc. One of the specifications of this series is convenient for assembly, and the other is convenient for a single worker to construct on site without the need for multiple workers to cooperate and assemble, saving construction costs .

[0055] 2. Excavate the upper soil body 11, trim the slope manually, and start laying the bamboo strips 2 on the slope top and slope surface. The bamboo nails 3 reach the soil layer, and the bamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com