Adjustable base assembly structure of steel cofferdam

A technology for assembling structures and steel cofferdams, applied in infrastructure engineering, construction, etc., can solve the problems of complex construction and demolition procedures, difficult to adopt, high cost, and achieve stable and reliable overall structural strength, sufficient support and connection, and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

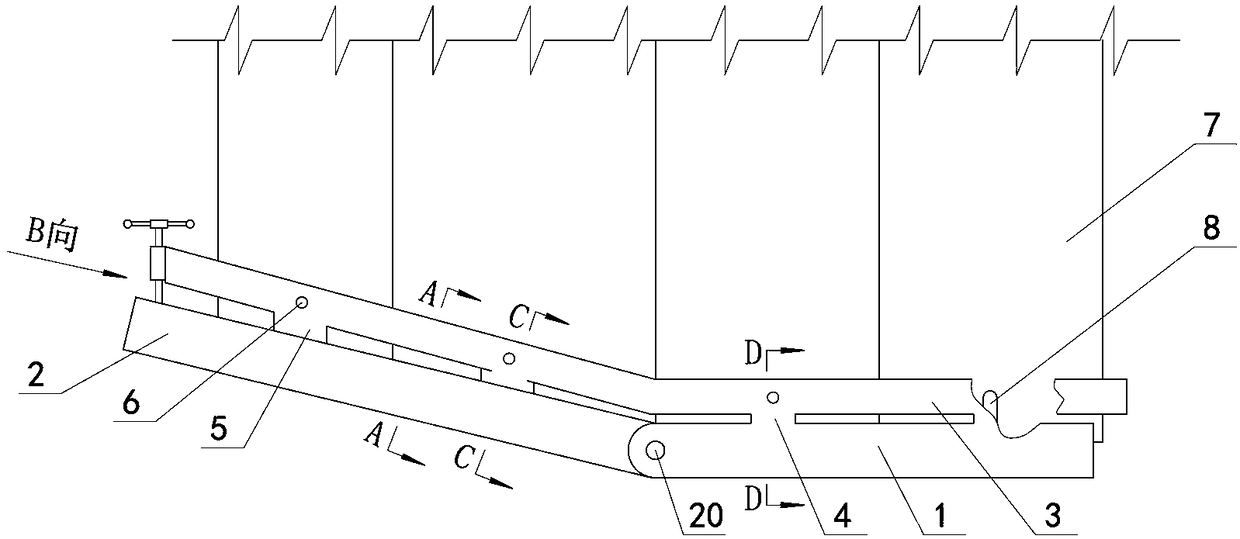

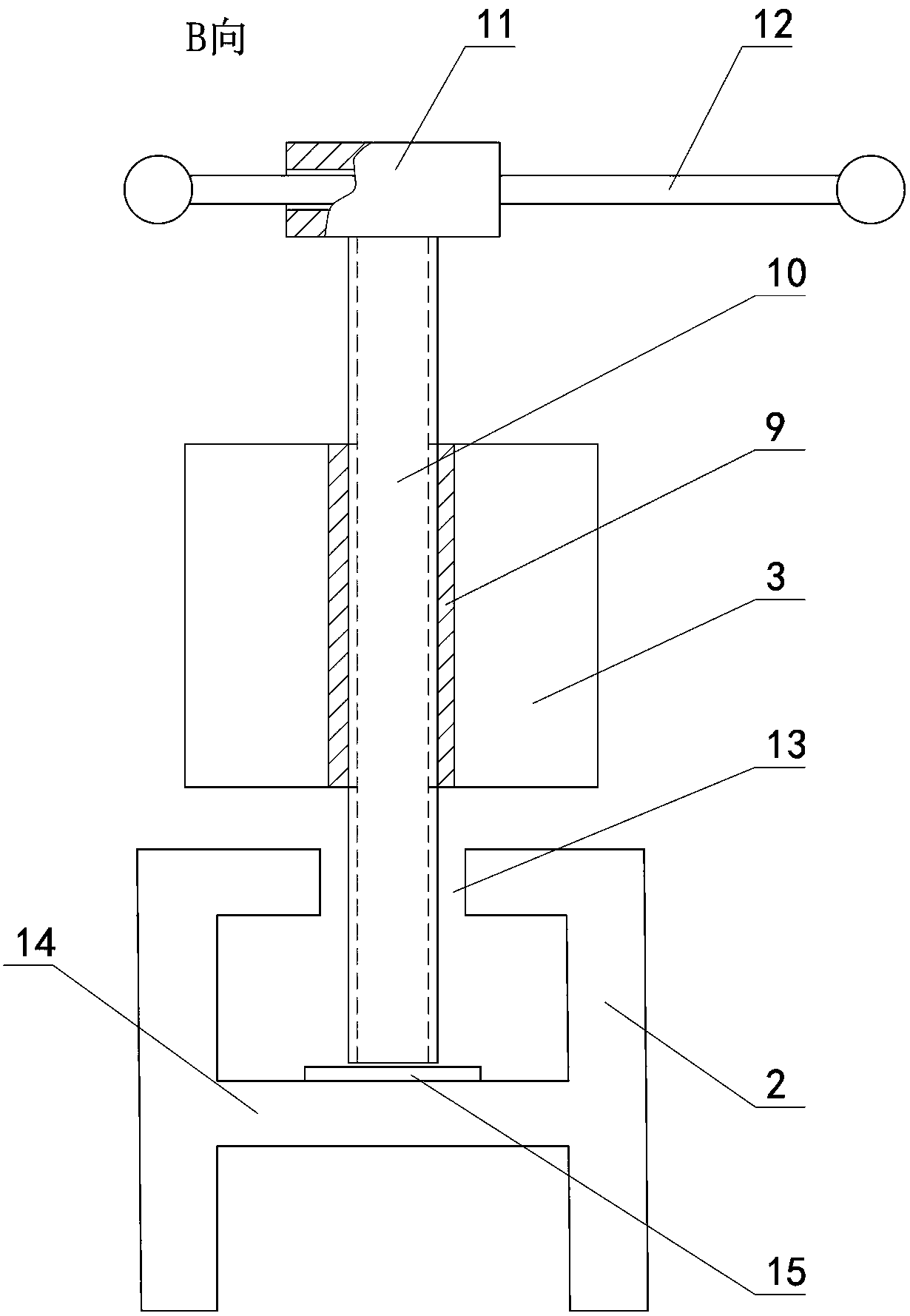

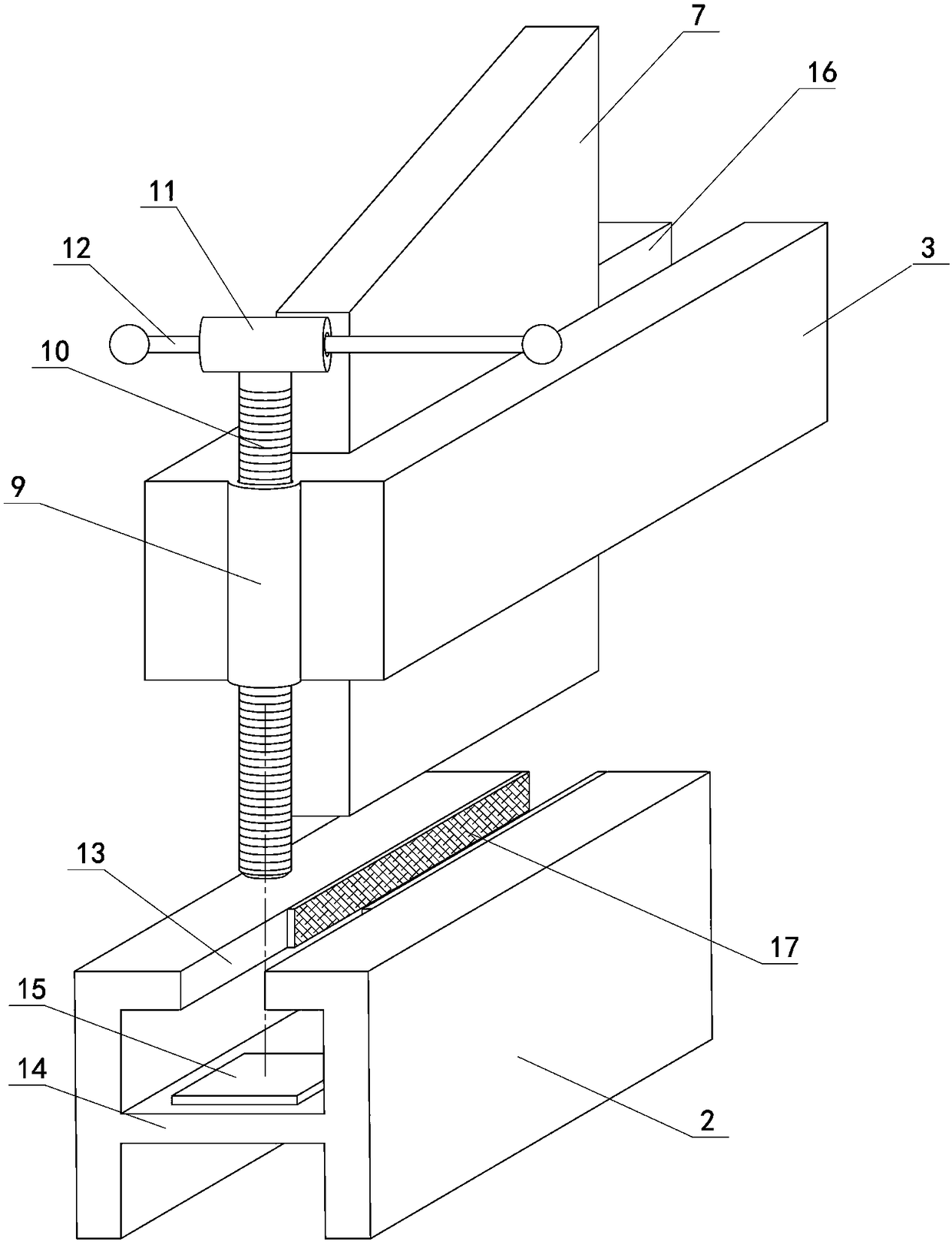

[0021] The river embankment cofferdam comprises each base and each cofferdam side which are fixed on the upper side of the river embankment and the river bed. Such as figure 1 As shown, the lower base and upper base 3 of the steel cofferdam, and the side plate 7 of the cofferdam. figure 1 Only the adjustable base assembly structure of the steel cofferdam is shown, through which the installation structure of the entire cofferdam can be understood.

[0022] Specifically, see figure 1 , Figure 7 with Figure 8 As shown, the lower base includes a horizontal lower base 1 and an inclined lower base 2 , which are hinged together through a rotating shaft 20 . Since the middle part of the horizontal lower base 1 and the inclined lower base 2 is provided with a bottom fitting groove 13, so the specific position of the hinge occurs on both side walls of the bottom fitting groove 13, as Figure 8 As shown, the threading pins 18 are respectively located on the two side walls of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com