Down-the-hole drill pipe improvement structure

A technology for down-the-hole drilling and drill pipes, which is applied in the direction of drill pipes, drill pipes, casings, etc. It can solve problems such as high energy consumption, insufficient fracture protection, and high noise, and achieve good safety performance, shorten airflow filling time, and reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

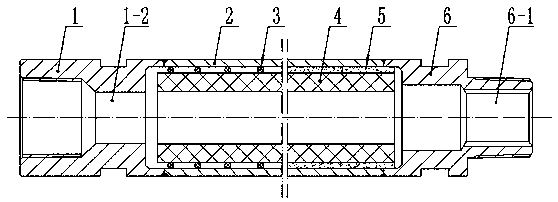

[0016] Such as figure 1 As shown: the drill pipe body consists of a steel pipe body 2, a female threaded joint 1 welded to the left end of the pipe body, and a male threaded joint 6 welded to the other right end of the pipe body. The female threaded joint 1 has a female threaded joint airflow The channel 1-2 and the male threaded joint 6 have a male threaded joint air flow channel 6-1 inside. The pipe body 2 is filled with a PVC lining pipe 4 whose length is suitable for it, and the inner diameter of the PVC lining pipe is the same as the diameter of the airflow channel 6-1 of the male thread joint and the airflow channel 1-2 of the female thread joint.

[0017] In order to fix the PVC inner pipe 4, there is a flexible filling layer between the VC inner pipe 4 and the pipe body 2. The flexible filling layer can be made of several sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com