a leaf spring

A technology of leaf springs and leaf springs, applied in the direction of springs, low internal friction springs, springs/shock absorbers, etc., can solve problems such as temperature rise of leaf springs, increased frictional force, and decreased comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

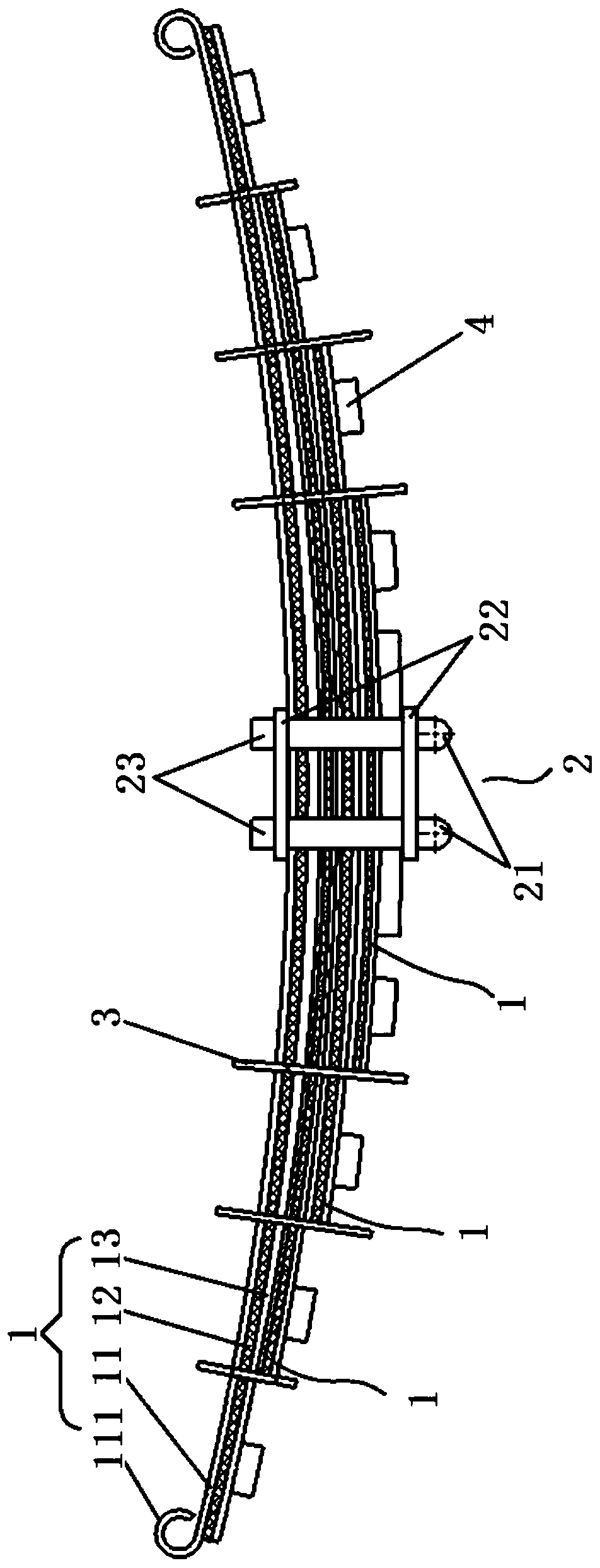

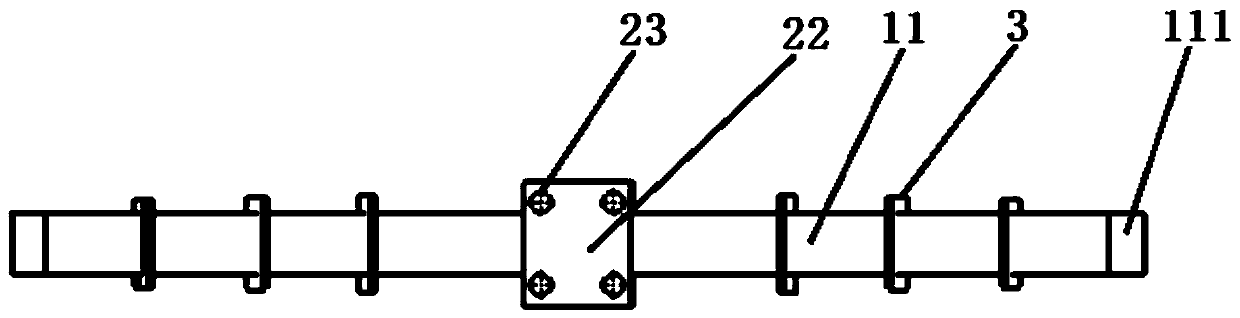

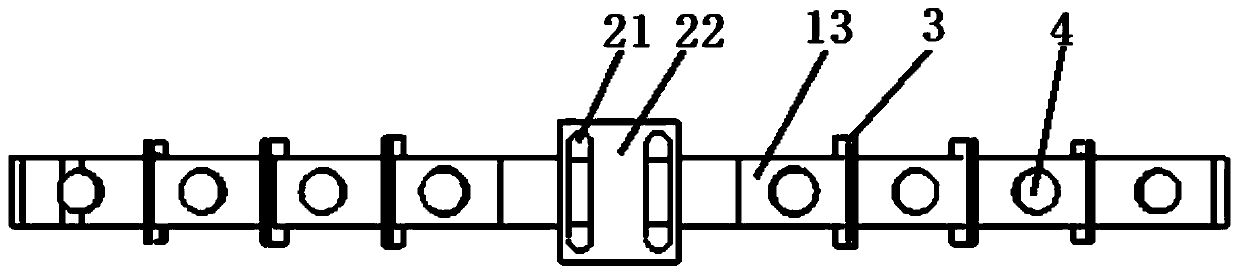

[0028] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. The directional nouns such as "up" and "down" mentioned in this article are based on figure 1 The orientation in is for reference.

[0029] refer to Figure 1 to Figure 5 , the present embodiment provides a leaf spring, the whole shape of which is a downwardly protruding arc, specifically including a plurality of plate assemblies 1 , bolt assemblies 2 , a plurality of buckles 3 and a plurality of electromagnet assemblies 4 .

[0030] Wherein, a plurality of plate assemblies 1 are stacked up and down, and the lengths of the plurality of plate assemblies 1 decrease sequentially along the direction from top to bottom. Moreover, in every two adjacent panel assemblies 1 up and down, the two ends of the lower panel assembly 1 have the same indentation size relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com