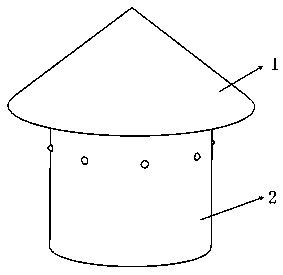

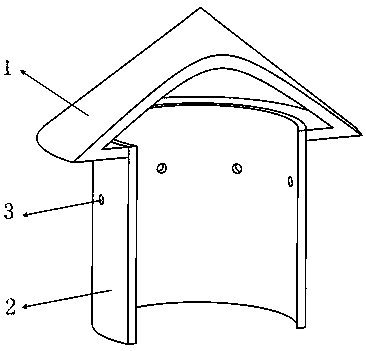

Anti-blocking boiler air cap applied to power station field

A technology for power plants and air caps, which is applied in the field of anti-blocking boiler air caps, and can solve problems such as troublesome checking and blocking of air caps, easy access, and blockage of air cap holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

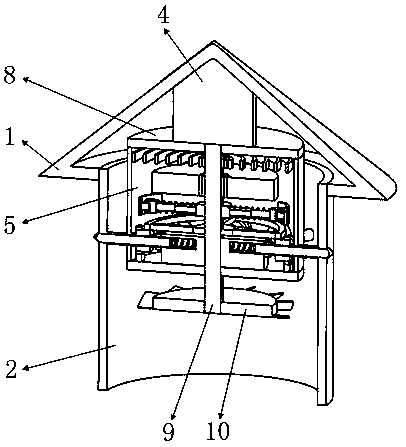

specific Embodiment approach

[0079] Specific embodiments: when no air is blown into the hood cover 2, the turbine 10 does not rotate, the rotating shaft 9 does not rotate, the scroll spring 25 is not compressed; the heavy U-shaped block 28 does not rotate, and the telescopic rod spring 44 is in an unstretched state Eight executive rods 19 have one end of the tapered end 43 to pass through eight wind cap holes 3; the external thread 40 on the executive rod 19 is threadedly matched with the internal thread of the threaded sleeve 32 near one end of the connecting swivel 37, and the disc spring 33 is in the Stretched state.

[0080] Set the maximum compression amount of the scroll spring 25 to 10 turns, and after the rotation speed of the rotating shaft 9 reaches V0, the centrifugal force generated by the heavy U-shaped block 28 is enough to make the arc-shaped pendulum plate 29 contact with the inner circular surface of the ring shell 15.

[0081] When high-pressure and high-speed air is blown into the hood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com