Screw rod type wet-process oil smoke purification system

A kind of oil fume purification and screw type technology, which is applied in the field of oil fume extraction system, can solve the problems of expensive initial investment, and achieve the effect of avoiding fire hazards and sanitary hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

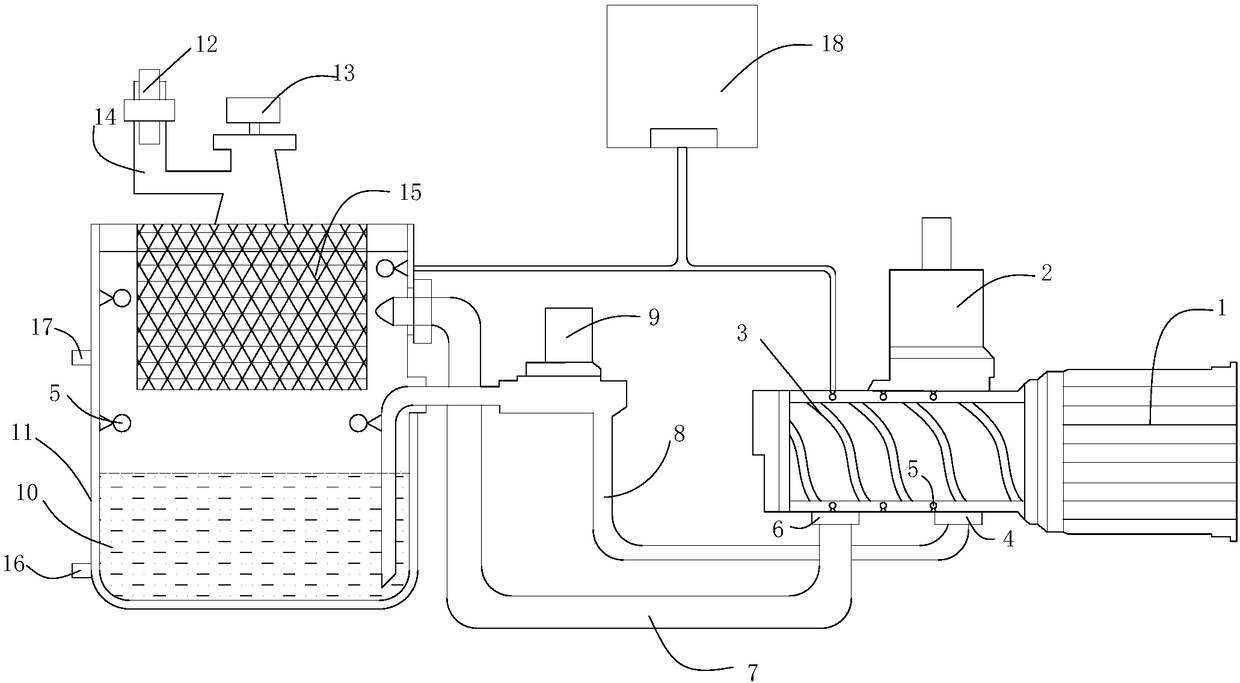

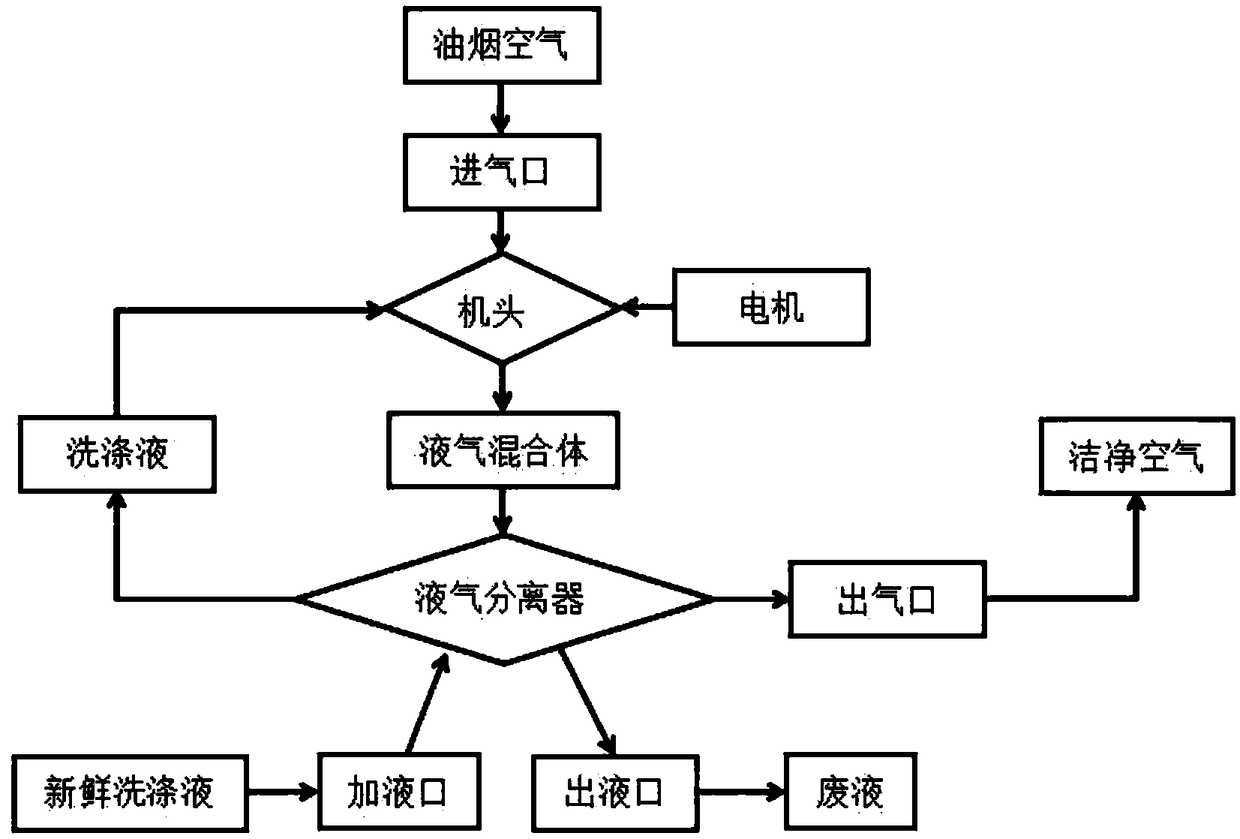

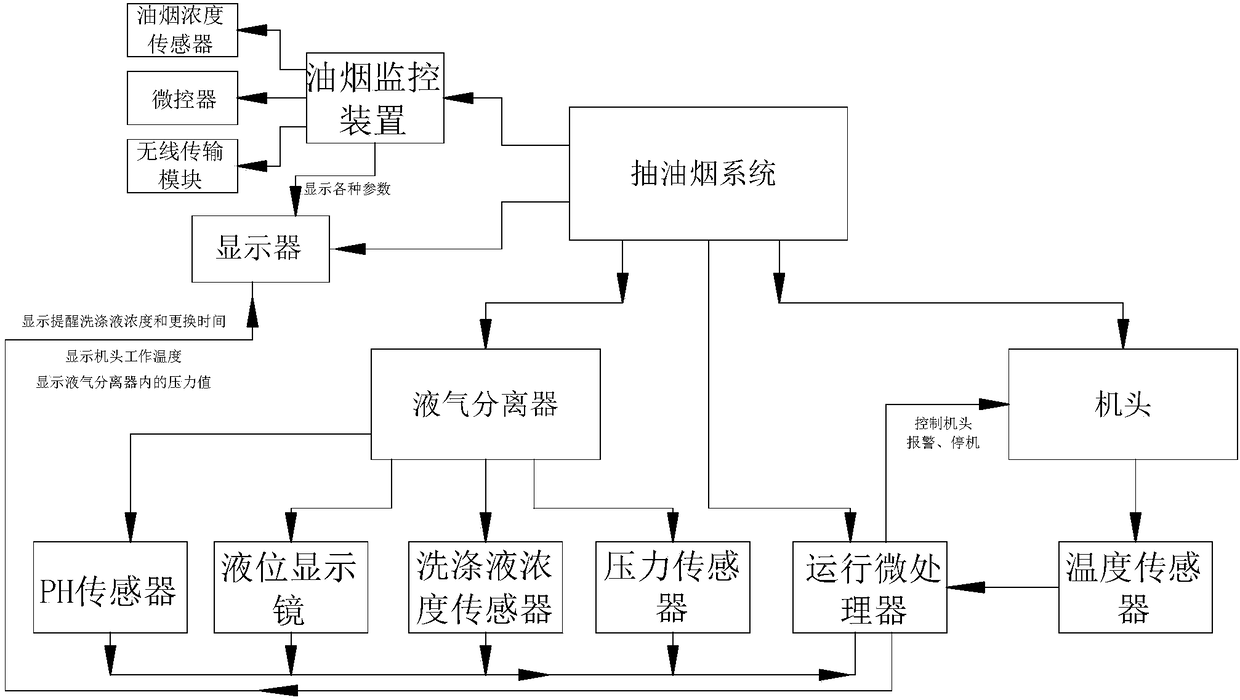

[0023] figure 1 , figure 2 middle, image 3 , a screw-type wet oil fume purification system, including a screw-type head 3 connected to a high-speed motor 1, and connected to an indoor oil fume inlet; The washing liquid 10 is transported to the washing liquid conveying device in the head 3 at high pressure, one end is connected to the head 3, and the other end is connected to the liquid-gas separator and placed in the washing liquid 10; the oil and gas are transported from the head 3 to the liquid-gas separator. The liquid and gas output pipe 7 is connected to the machine head 3 at one end and the liquid-gas separator at the other end; when the screw head 3 rotates and stirs at a high speed, the oil fume and the washing liquid 10 are quickly inhaled, and the oil fume and the incoming washing liquid 10 are in the machine The inside of the head 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com