Displacement ventilation dusting equipment used for workshop

A technology for replacing ventilation and dust removal equipment, which is applied to ventilation systems, mechanical equipment, lighting and heating equipment, etc. It can solve the problems of no self-cleaning structure of the dustproof filter, blockage of the filter, and influence on stability, so as to improve indoor air Excellent quality, dust reduction, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

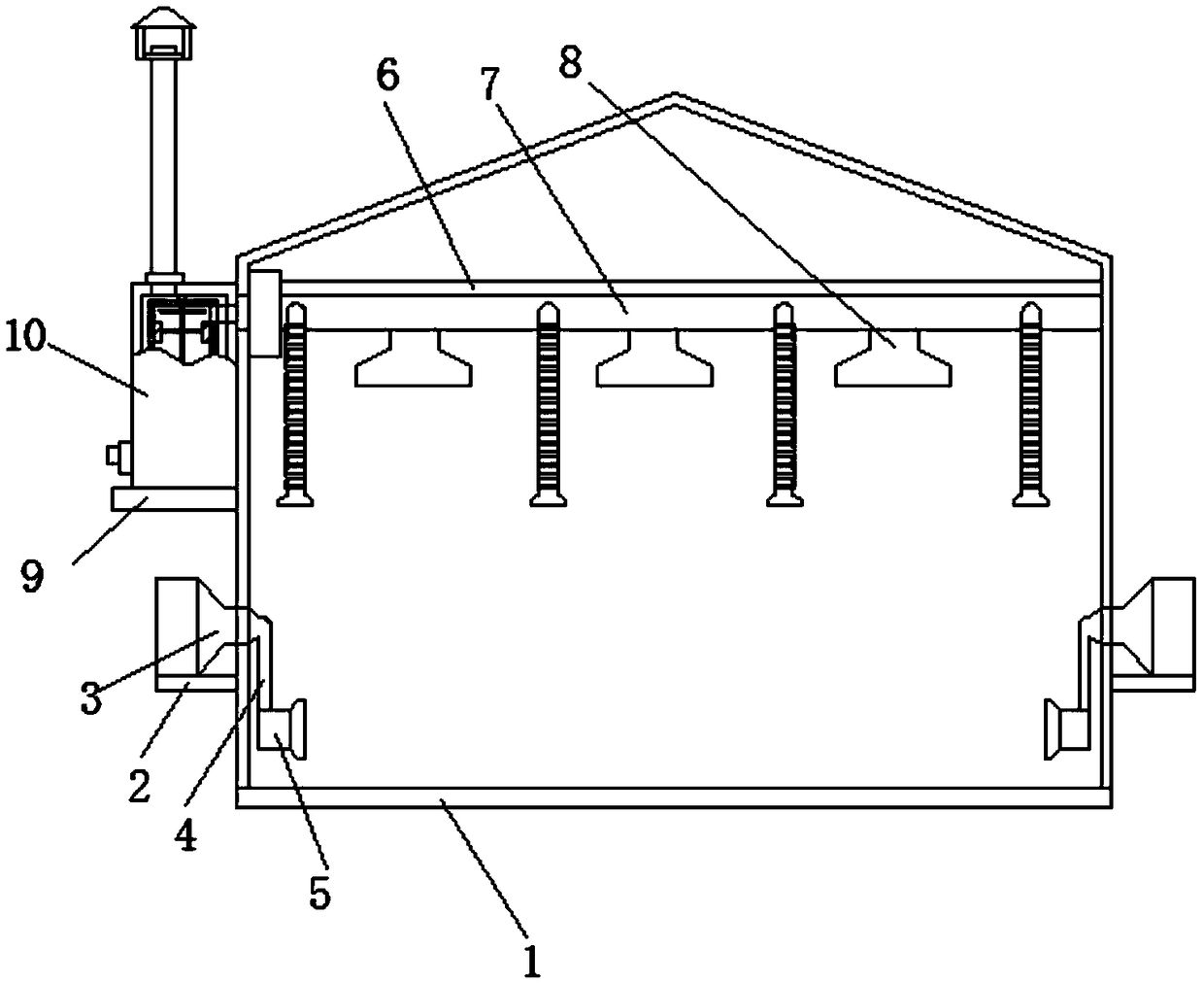

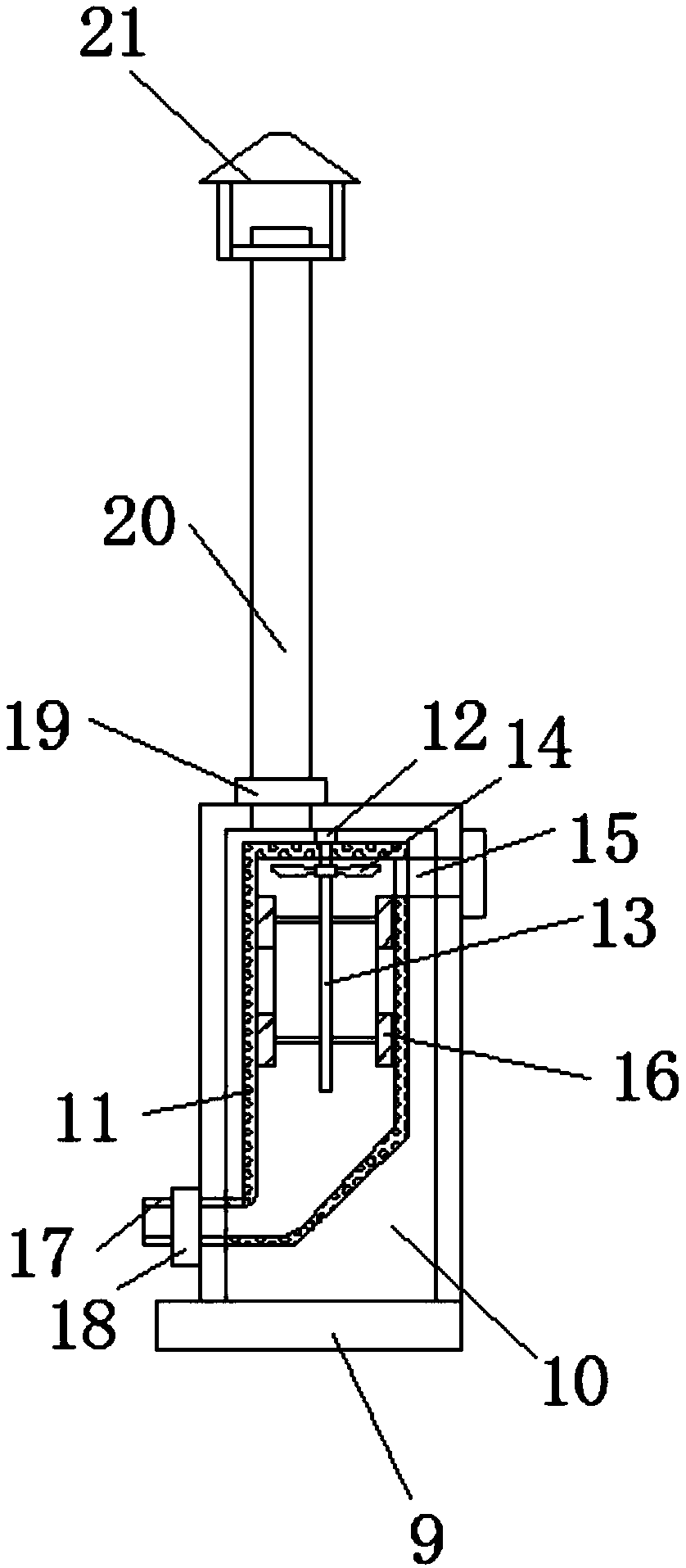

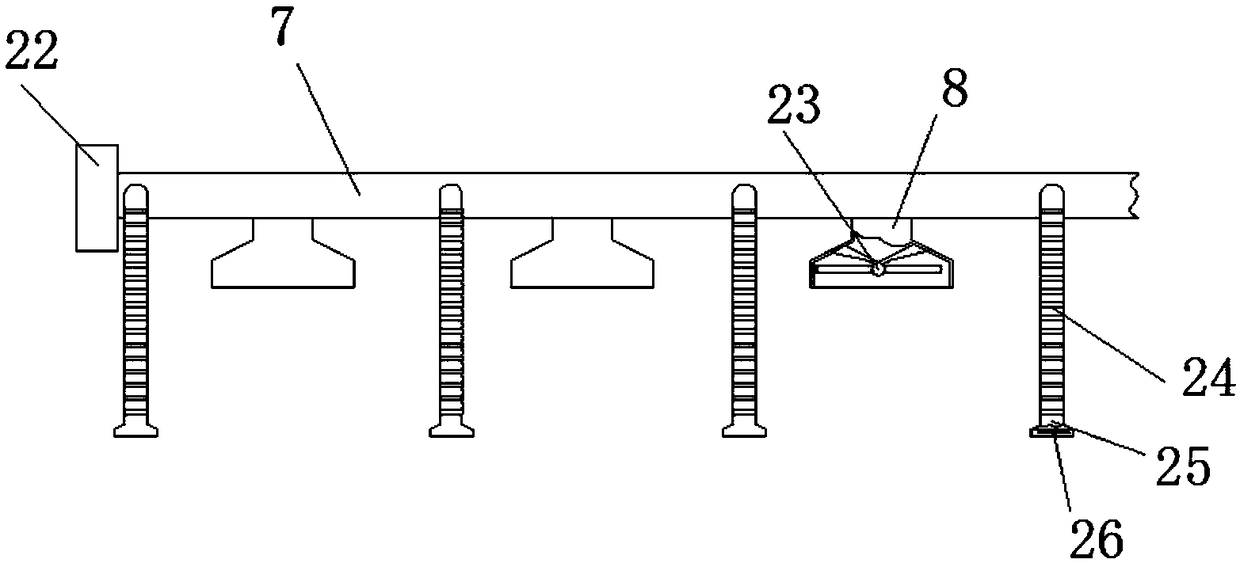

[0025] Embodiment one: refer to Figure 1-4 , a kind of replacement ventilation and dust removal equipment for a factory building, comprising a factory building body 1, a blower 3 is symmetrically fixed on the outer walls of both sides of the factory building body 1 through a first fixing seat 2, and the blower 3 is connected to an exhaust hood 5 through an air pipe 4, and The air pipe 4 runs through the plant body 1, the exhaust hood 5 is located inside the plant body 1, the top of the plant body 1 is welded with a beam 6, the beam 6 is fixed with an exhaust pipe 7, and the exhaust pipe 7 is connected to the first suction pipe 7. Cover 8, a purifier 10 is fixed on the outer wall of one side of the plant body 1 through the second fixed seat 9, a filter cover 11 is clamped inside the purifier 10, a swivel seat 12 is fixed at the center of the top plate inside the purifier 10, and the swivel seat The top of 12 is fixed with a rotating shaft 13, and the rotating shaft 13 runs thr...

Embodiment 2

[0026] Embodiment two: refer to figure 1 and image 3 , the exhaust pipe 7 is conductively connected with the filter cover 11 inside the purifier 10 through the air intake pipe 15, and the second suction cover 25 is connected to the exhaust pipe 7 through a hose 24, and the inner bolts of the second suction cover 25 A second suction fan 26 is fixed, and a plurality of first suction hoods 8 are arranged in total, and a plurality of first suction hoods 8 are equidistantly arranged on the exhaust pipe 7, and the first suction hoods 8 are used for suctioning the factory building. The air in the body 1 is replaced by air. The second suction hood 25 can be fixed in the area where the dust gas is generated inside the plant body 1 through the stretching of the hose 24, and the generated dust gas can be directly discharged, which is beneficial to reduce Dust, improve indoor air quality.

Embodiment 3

[0027] Embodiment three: refer to Figure 1-2 , the top of the purifier 10 is connected with an exhaust pipe 20, a waterproof cover 21 is fixed at the top opening of the exhaust pipe 20, and a second control valve 19 is fixed on the exhaust pipe 20, and the second control valve 19 is used to control the exhaust The conduction and closing of the pipe 20, the waterproof cover 21 is used to place the exhaust pipe 20 to enter water and improve its waterproof ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com