Full-steam water heater

A water heater and full steam technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of short holding time, low utilization rate of heat energy, uneven water temperature, etc., and achieve long holding time and thermal energy. The effect of high utilization rate and uniform water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

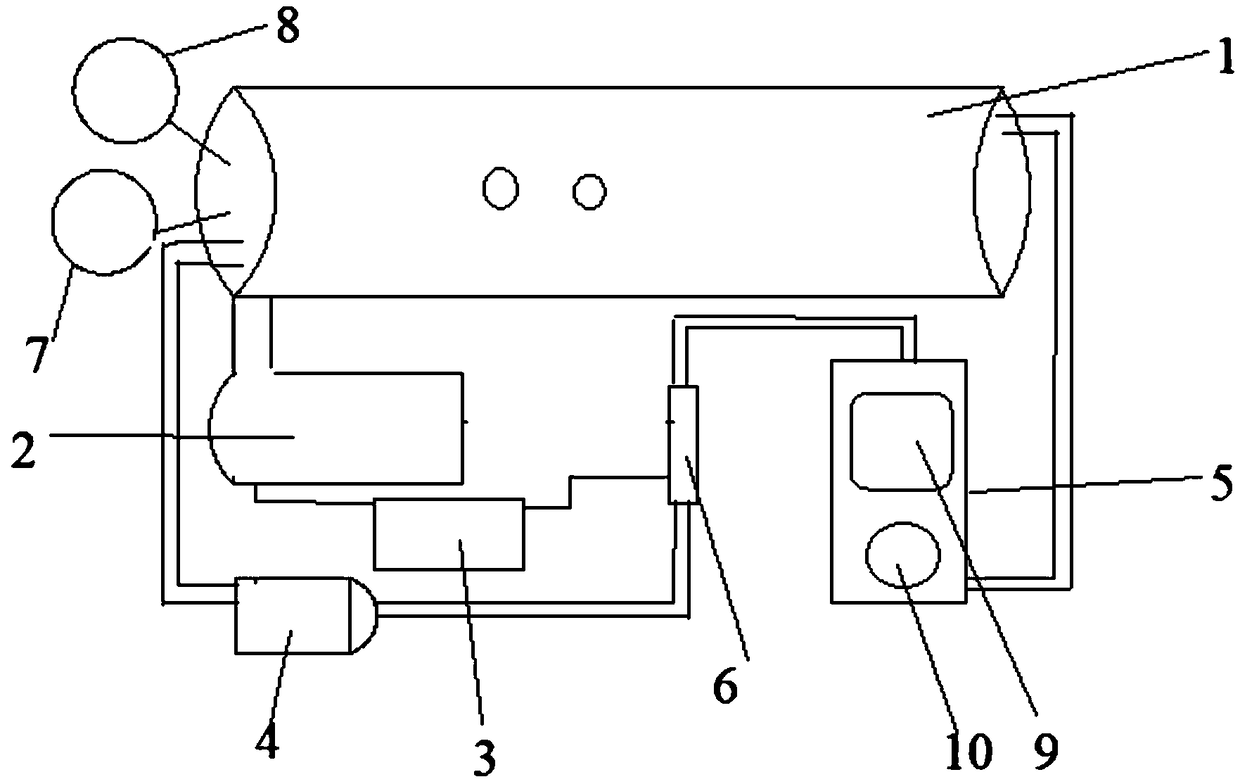

[0020] Such as Figure 1-Figure 2 As shown, a full-steam water heater includes a heat exchange tank 1, a liquid tank 2, a motor 3, a compressor 4, an atomizing tank 5, an electromagnetic heater 6, and pipes and wires for connecting instruments; the heat exchange tank The front end of 1 is connected to the input end of compressor 4 through a pipeline; the lower edge of the front end of the heat exchange tank 1 is connected to a liquid tank 2 through a pipeline; one end of the liquid tank 2 is provided with an electrical interface connected to the motor 3 through a wire, It is electrically connected with the atomizing tank 5; the input end of the electromagnetic heater 6 is connected with the output end of the compressor 4; the output end of the electromagnetic heater 6 is connected with the upper inlet of the atomizing tank 5; the atomizing The outlet at the lower end of the tank 5 is connected to the steam inlet on the upper edge of the rear end of the heat exchange tank 1 . ...

specific Embodiment approach

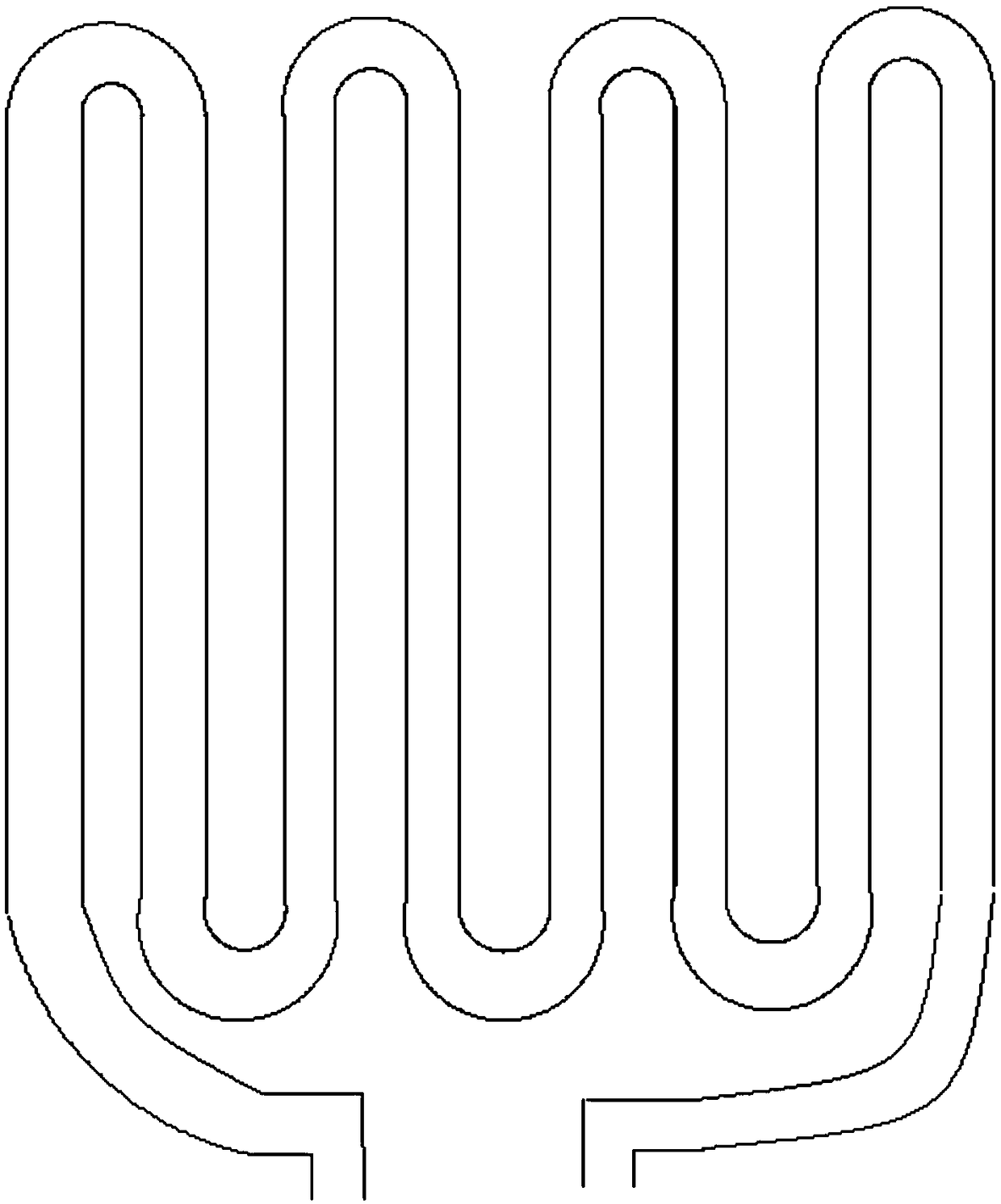

[0027] Specific implementation method: first, the liquid in the liquid tank is sent to the electromagnetic heater through the compressor and the motor, and the liquid is sent to the atomization tank after being heated, and then enters the gas-liquid separator to separate excess gas impurities, and separates out The liquid continues to be sent to the atomizing head in the atomizing tank, and the liquid is atomized by the atomizing head, and the steam is sent to the heat exchange tank, and the pipes arranged in S shape between the steam and the cold water outlet and the hot water outlet, Full heat exchange is carried out, and finally hot water with uniform temperature flows out from the hot water outlet. After the heat exchange of the steam, the temperature drops, and it will condense into a liquid. According to the principle of gravity, it will flow into the liquid tank for temporary storage. As the whole system continues, the liquid in the liquid tank will be sent to the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com